Are you a seasoned Production Technologist seeking a new career path? Discover our professionally built Production Technologist Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

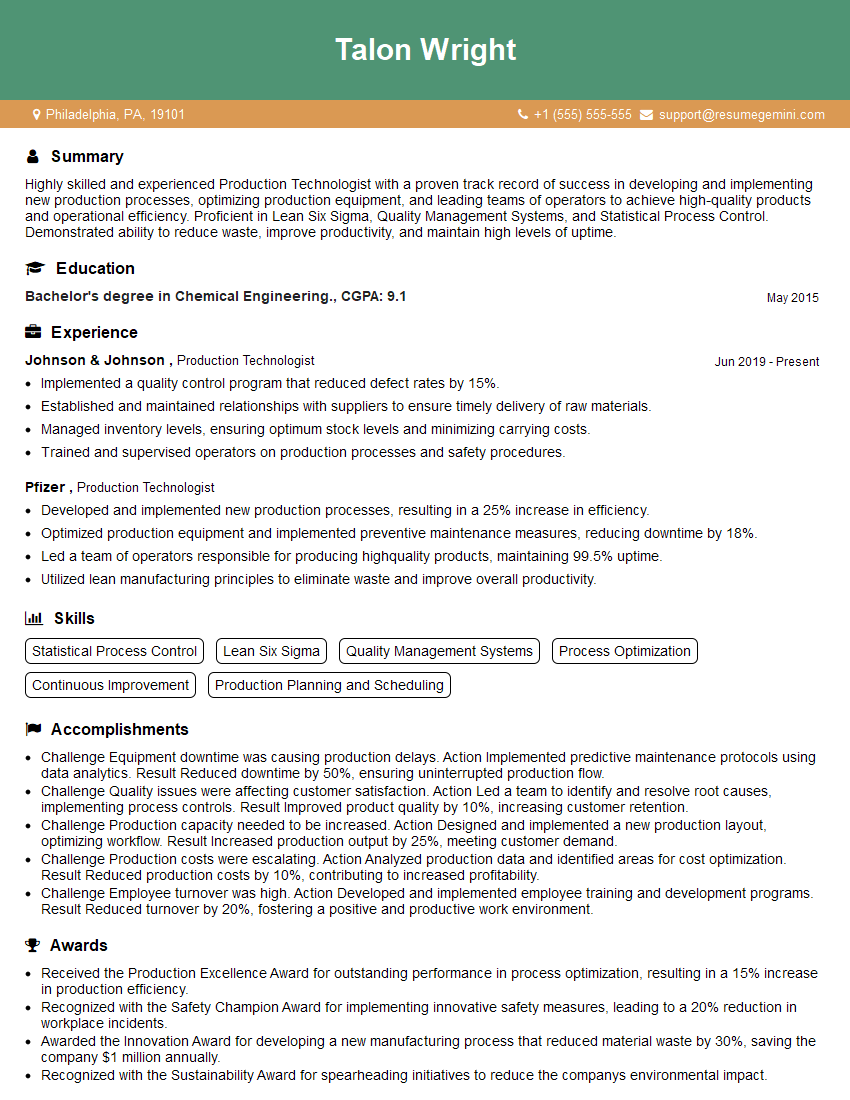

Talon Wright

Production Technologist

Summary

Highly skilled and experienced Production Technologist with a proven track record of success in developing and implementing new production processes, optimizing production equipment, and leading teams of operators to achieve high-quality products and operational efficiency. Proficient in Lean Six Sigma, Quality Management Systems, and Statistical Process Control. Demonstrated ability to reduce waste, improve productivity, and maintain high levels of uptime.

Education

Bachelor’s degree in Chemical Engineering.

May 2015

Skills

- Statistical Process Control

- Lean Six Sigma

- Quality Management Systems

- Process Optimization

- Continuous Improvement

- Production Planning and Scheduling

Work Experience

Production Technologist

- Implemented a quality control program that reduced defect rates by 15%.

- Established and maintained relationships with suppliers to ensure timely delivery of raw materials.

- Managed inventory levels, ensuring optimum stock levels and minimizing carrying costs.

- Trained and supervised operators on production processes and safety procedures.

Production Technologist

- Developed and implemented new production processes, resulting in a 25% increase in efficiency.

- Optimized production equipment and implemented preventive maintenance measures, reducing downtime by 18%.

- Led a team of operators responsible for producing highquality products, maintaining 99.5% uptime.

- Utilized lean manufacturing principles to eliminate waste and improve overall productivity.

Accomplishments

- Challenge Equipment downtime was causing production delays. Action Implemented predictive maintenance protocols using data analytics. Result Reduced downtime by 50%, ensuring uninterrupted production flow.

- Challenge Quality issues were affecting customer satisfaction. Action Led a team to identify and resolve root causes, implementing process controls. Result Improved product quality by 10%, increasing customer retention.

- Challenge Production capacity needed to be increased. Action Designed and implemented a new production layout, optimizing workflow. Result Increased production output by 25%, meeting customer demand.

- Challenge Production costs were escalating. Action Analyzed production data and identified areas for cost optimization. Result Reduced production costs by 10%, contributing to increased profitability.

- Challenge Employee turnover was high. Action Developed and implemented employee training and development programs. Result Reduced turnover by 20%, fostering a positive and productive work environment.

Awards

- Received the Production Excellence Award for outstanding performance in process optimization, resulting in a 15% increase in production efficiency.

- Recognized with the Safety Champion Award for implementing innovative safety measures, leading to a 20% reduction in workplace incidents.

- Awarded the Innovation Award for developing a new manufacturing process that reduced material waste by 30%, saving the company $1 million annually.

- Recognized with the Sustainability Award for spearheading initiatives to reduce the companys environmental impact.

Certificates

- ASQ Certified Quality Engineer

- ASQ Certified Manager of Quality/Operational Excellence

- PMI Certified Project Manager

- Certified Manufacturing Technologist

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Production Technologist

- Highlight your experience in developing and implementing new production processes that have resulted in significant efficiency gains.

- Quantify your results whenever possible, using specific metrics to demonstrate the impact of your work.

- Emphasize your skills in Lean Six Sigma, Quality Management Systems, and Statistical Process Control.

- Showcase your ability to lead teams and motivate operators to achieve high levels of performance.

- Tailor your resume to the specific requirements of each job you apply for, highlighting the skills and experience that are most relevant to the position.

Essential Experience Highlights for a Strong Production Technologist Resume

- Develop and implement new production processes to improve efficiency and reduce costs.

- Optimize production equipment and implement preventive maintenance measures to minimize downtime.

- Lead teams of operators responsible for producing high-quality products and maintaining operational efficiency.

- Utilize Lean Six Sigma principles to eliminate waste and improve overall productivity.

- Implement and maintain quality control programs to reduce defect rates and ensure product quality.

- Establish and maintain relationships with suppliers to ensure timely delivery of raw materials.

- Manage inventory levels to optimize stock levels and minimize carrying costs.

Frequently Asked Questions (FAQ’s) For Production Technologist

What is the role of a Production Technologist?

A Production Technologist is responsible for developing and implementing production processes that ensure the efficient and cost-effective manufacture of products. They work to optimize production equipment, reduce waste, and improve overall productivity.

What are the key skills required for a Production Technologist?

Key skills for a Production Technologist include proficiency in Lean Six Sigma, Quality Management Systems, and Statistical Process Control. They should also have a strong understanding of production processes, equipment maintenance, and inventory management.

What is the career path for a Production Technologist?

Production Technologists can advance to roles such as Production Manager, Operations Manager, or Plant Manager. With additional experience and education, they may also pursue careers in research and development or consulting.

What are the challenges faced by Production Technologists?

Production Technologists face challenges such as the need to continuously improve efficiency and reduce costs, while ensuring product quality and meeting customer demands. They must also stay abreast of new technologies and best practices in the manufacturing industry.

What is the job outlook for Production Technologists?

The job outlook for Production Technologists is expected to be favorable due to the increasing demand for skilled professionals in the manufacturing sector. As companies strive to improve efficiency and productivity, the need for Production Technologists will continue to grow.

What are the earning potential for Production Technologists?

The earning potential for Production Technologists varies depending on their experience, skills, and location. According to the U.S. Bureau of Labor Statistics, the median annual salary for Production Technologists is around $60,000.

What are the educational requirements for becoming a Production Technologist?

Most Production Technologists have a bachelor’s degree in Chemical Engineering, Industrial Engineering, or a related field. Some employers may also accept candidates with an associate’s degree in a technical field and relevant work experience.