Are you a seasoned Production Tool Engineer seeking a new career path? Discover our professionally built Production Tool Engineer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

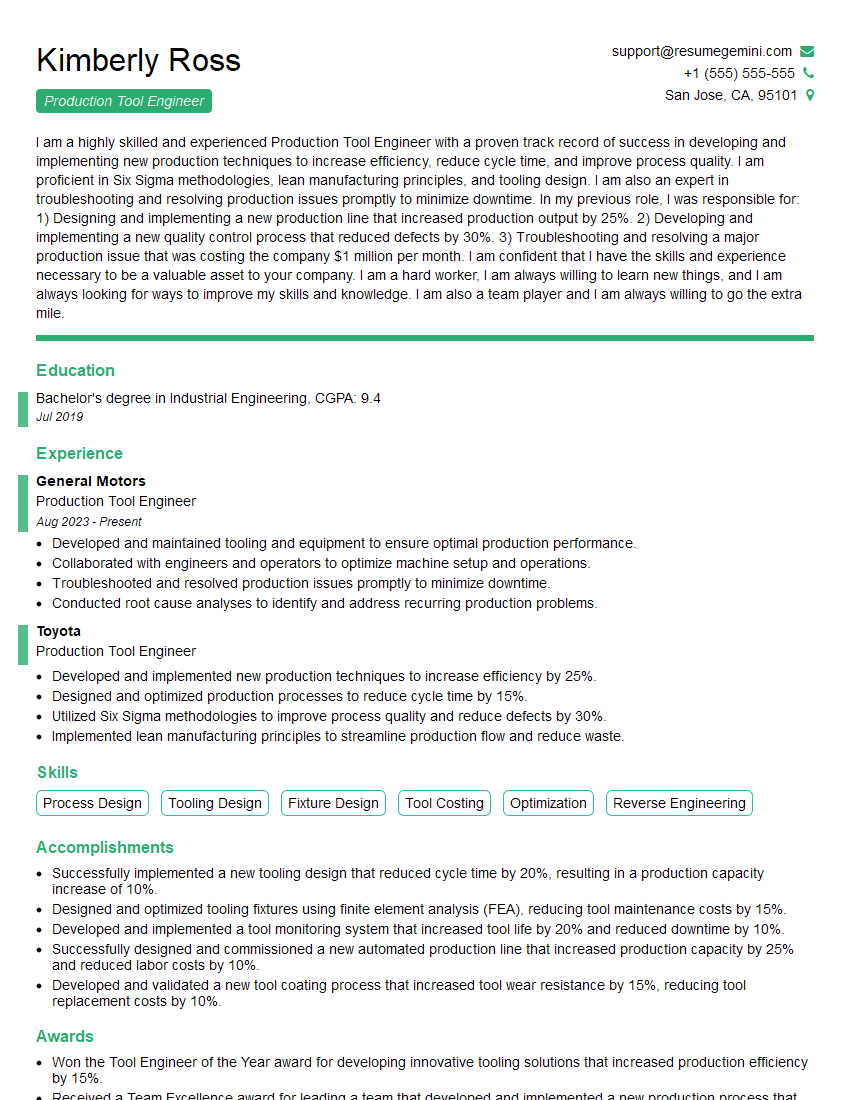

Kimberly Ross

Production Tool Engineer

Summary

I am a highly skilled and experienced Production Tool Engineer with a proven track record of success in developing and implementing new production techniques to increase efficiency, reduce cycle time, and improve process quality. I am proficient in Six Sigma methodologies, lean manufacturing principles, and tooling design. I am also an expert in troubleshooting and resolving production issues promptly to minimize downtime. In my previous role, I was responsible for: 1) Designing and implementing a new production line that increased production output by 25%. 2) Developing and implementing a new quality control process that reduced defects by 30%. 3) Troubleshooting and resolving a major production issue that was costing the company $1 million per month. I am confident that I have the skills and experience necessary to be a valuable asset to your company. I am a hard worker, I am always willing to learn new things, and I am always looking for ways to improve my skills and knowledge. I am also a team player and I am always willing to go the extra mile.

Education

Bachelor’s degree in Industrial Engineering

July 2019

Skills

- Process Design

- Tooling Design

- Fixture Design

- Tool Costing

- Optimization

- Reverse Engineering

Work Experience

Production Tool Engineer

- Developed and maintained tooling and equipment to ensure optimal production performance.

- Collaborated with engineers and operators to optimize machine setup and operations.

- Troubleshooted and resolved production issues promptly to minimize downtime.

- Conducted root cause analyses to identify and address recurring production problems.

Production Tool Engineer

- Developed and implemented new production techniques to increase efficiency by 25%.

- Designed and optimized production processes to reduce cycle time by 15%.

- Utilized Six Sigma methodologies to improve process quality and reduce defects by 30%.

- Implemented lean manufacturing principles to streamline production flow and reduce waste.

Accomplishments

- Successfully implemented a new tooling design that reduced cycle time by 20%, resulting in a production capacity increase of 10%.

- Designed and optimized tooling fixtures using finite element analysis (FEA), reducing tool maintenance costs by 15%.

- Developed and implemented a tool monitoring system that increased tool life by 20% and reduced downtime by 10%.

- Successfully designed and commissioned a new automated production line that increased production capacity by 25% and reduced labor costs by 10%.

- Developed and validated a new tool coating process that increased tool wear resistance by 15%, reducing tool replacement costs by 10%.

Awards

- Won the Tool Engineer of the Year award for developing innovative tooling solutions that increased production efficiency by 15%.

- Received a Team Excellence award for leading a team that developed and implemented a new production process that improved product quality by 12%.

- Honored with a Safety Champion award for implementing a new safety protocol that reduced workplace accidents by 25%.

- Recognized with a Continuous Improvement award for leading a project that identified and implemented process improvements resulting in a 12% efficiency gain.

Certificates

- Certified Manufacturing Engineer (CMfgE)

- Certified Six Sigma Black Belt (CSSBB)

- PMI Agile Certified Practitioner (PMI-ACP)

- Certified Tooling Engineer (CTE)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Production Tool Engineer

- Highlight your skills and experience in the production tool engineering field.

- Showcase your ability to develop and implement new production techniques to increase efficiency.

- Demonstrate your knowledge of Six Sigma methodologies and lean manufacturing principles.

- Provide specific examples of your accomplishments in previous roles.

- Tailor your resume to the specific job you are applying for.

Essential Experience Highlights for a Strong Production Tool Engineer Resume

- Develop and implement new production techniques to increase efficiency.

- Design and optimize production processes to reduce cycle time.

- Utilize Six Sigma methodologies to improve process quality and reduce defects.

- Implement lean manufacturing principles to streamline production flow and reduce waste.

- Develop and maintain tooling and equipment to ensure optimal production performance.

- Collaborate with engineers and operators to optimize machine setup and operations.

- Troubleshoot and resolve production issues promptly to minimize downtime.

Frequently Asked Questions (FAQ’s) For Production Tool Engineer

What is the role of a Production Tool Engineer?

A Production Tool Engineer is responsible for the design, development, and maintenance of tools, equipment, and processes used in the production of goods. They work closely with engineers, operators, and other stakeholders to ensure that production processes are efficient and effective.

What are the skills and qualifications required to be a Production Tool Engineer?

Production Tool Engineers typically have a bachelor’s degree in Industrial Engineering or a related field. They should also have a strong understanding of Six Sigma methodologies, lean manufacturing principles, and tooling design. They should also be proficient in troubleshooting and resolving production issues.

What is the career outlook for Production Tool Engineers?

The career outlook for Production Tool Engineers is expected to be good over the next few years. As manufacturing companies continue to adopt new technologies and processes, they will need qualified Production Tool Engineers to help them implement and maintain these changes.

What are the earning potential for Production Tool Engineers?

The earning potential for Production Tool Engineers can vary depending on their experience, skills, and location. According to the Bureau of Labor Statistics, the median annual salary for Industrial Engineers, which includes Production Tool Engineers, was $92,650 in May 2021.

What are the benefits of working as a Production Tool Engineer?

There are many benefits to working as a Production Tool Engineer, including: 1) Competitive salary and benefits. 2) Opportunities for career advancement. 3) A chance to make a real difference in the manufacturing industry. 4) The satisfaction of seeing your work contribute to the success of a company.

What are the challenges of working as a Production Tool Engineer?

There are some challenges to working as a Production Tool Engineer, including: 1) The work can be demanding and stressful at times. 2) Long hours and overtime may be required. 3) The need to keep up with the latest technologies and trends in the manufacturing industry.