Are you a seasoned Progressive Assembler and Fitter seeking a new career path? Discover our professionally built Progressive Assembler and Fitter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

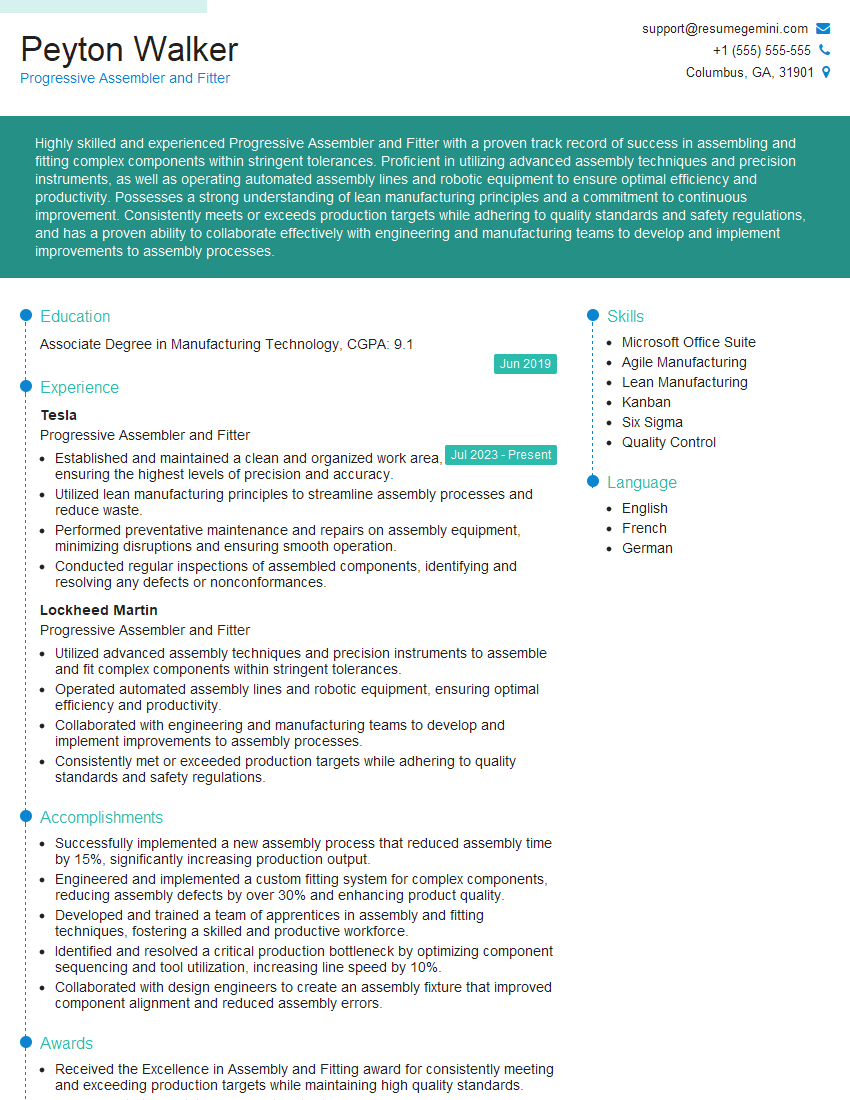

Peyton Walker

Progressive Assembler and Fitter

Summary

Highly skilled and experienced Progressive Assembler and Fitter with a proven track record of success in assembling and fitting complex components within stringent tolerances. Proficient in utilizing advanced assembly techniques and precision instruments, as well as operating automated assembly lines and robotic equipment to ensure optimal efficiency and productivity. Possesses a strong understanding of lean manufacturing principles and a commitment to continuous improvement. Consistently meets or exceeds production targets while adhering to quality standards and safety regulations, and has a proven ability to collaborate effectively with engineering and manufacturing teams to develop and implement improvements to assembly processes.

Education

Associate Degree in Manufacturing Technology

June 2019

Skills

- Microsoft Office Suite

- Agile Manufacturing

- Lean Manufacturing

- Kanban

- Six Sigma

- Quality Control

Work Experience

Progressive Assembler and Fitter

- Established and maintained a clean and organized work area, ensuring the highest levels of precision and accuracy.

- Utilized lean manufacturing principles to streamline assembly processes and reduce waste.

- Performed preventative maintenance and repairs on assembly equipment, minimizing disruptions and ensuring smooth operation.

- Conducted regular inspections of assembled components, identifying and resolving any defects or nonconformances.

Progressive Assembler and Fitter

- Utilized advanced assembly techniques and precision instruments to assemble and fit complex components within stringent tolerances.

- Operated automated assembly lines and robotic equipment, ensuring optimal efficiency and productivity.

- Collaborated with engineering and manufacturing teams to develop and implement improvements to assembly processes.

- Consistently met or exceeded production targets while adhering to quality standards and safety regulations.

Accomplishments

- Successfully implemented a new assembly process that reduced assembly time by 15%, significantly increasing production output.

- Engineered and implemented a custom fitting system for complex components, reducing assembly defects by over 30% and enhancing product quality.

- Developed and trained a team of apprentices in assembly and fitting techniques, fostering a skilled and productive workforce.

- Identified and resolved a critical production bottleneck by optimizing component sequencing and tool utilization, increasing line speed by 10%.

- Collaborated with design engineers to create an assembly fixture that improved component alignment and reduced assembly errors.

Awards

- Received the Excellence in Assembly and Fitting award for consistently meeting and exceeding production targets while maintaining high quality standards.

- Honored with the Outstanding Contributor to Team Performance award for actively collaborating with team members and contributing innovative solutions to production challenges.

- Recognized as Production Supervisor of the Quarter for successfully mentoring and guiding a team of assemblers and fitters, resulting in improved efficiency and decreased rework rates.

Certificates

- Certified Production Technician

- Six Sigma Green Belt

- Lean Manufacturing Certification

- Quality Control Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Progressive Assembler and Fitter

- Highlight your skills in advanced assembly techniques and precision instruments.

- Quantify your accomplishments and provide specific examples of how you have improved assembly processes.

- Demonstrate your understanding of lean manufacturing principles and how you have applied them to streamline operations.

- Emphasize your ability to work effectively in a team environment and to collaborate with engineering and manufacturing teams.

- Showcase your commitment to quality and safety by providing examples of how you have consistently met or exceeded production targets while adhering to standards and regulations.

Essential Experience Highlights for a Strong Progressive Assembler and Fitter Resume

- Assemble and fit complex components within stringent tolerances using advanced assembly techniques and precision instruments.

- Operate automated assembly lines and robotic equipment to ensure optimal efficiency and productivity.

- Collaborate with engineering and manufacturing teams to develop and implement improvements to assembly processes.

- Consistently meet or exceed production targets while adhering to quality standards and safety regulations.

- Establish and maintain a clean and organized work area, ensuring the highest levels of precision and accuracy.

- Utilize lean manufacturing principles to streamline assembly processes and reduce waste.

- Perform preventative maintenance and repairs on assembly equipment, minimizing disruptions and ensuring smooth operation.

Frequently Asked Questions (FAQ’s) For Progressive Assembler and Fitter

What is the role of a Progressive Assembler and Fitter?

A Progressive Assembler and Fitter is responsible for assembling and fitting complex components within stringent tolerances using advanced assembly techniques and precision instruments. They operate automated assembly lines and robotic equipment to ensure optimal efficiency and productivity, and collaborate with engineering and manufacturing teams to develop and implement improvements to assembly processes.

What skills are required to be a successful Progressive Assembler and Fitter?

Successful Progressive Assemblers and Fitters possess skills in advanced assembly techniques, precision instruments, automated assembly lines, robotic equipment, lean manufacturing principles, and quality control. They are also proficient in Microsoft Office Suite and have a strong understanding of Agile Manufacturing, Kanban, Six Sigma, and Quality Control.

What are the career prospects for Progressive Assemblers and Fitters?

Progressive Assemblers and Fitters can advance their careers by becoming Supervisors, Managers, or Engineers in the manufacturing industry. They may also specialize in a particular area of assembly, such as electronics, automotive, or aerospace.

What is the average salary for Progressive Assemblers and Fitters?

The average salary for Progressive Assemblers and Fitters varies depending on experience, location, and industry. According to Salary.com, the average salary for Progressive Assemblers and Fitters in the United States is $25.50 per hour or $53,000 per year.

What is the job outlook for Progressive Assemblers and Fitters?

The job outlook for Progressive Assemblers and Fitters is expected to grow faster than average over the next decade. This is due to the increasing demand for manufactured goods and the need for skilled workers to operate and maintain automated assembly lines.

What are the benefits of working as a Progressive Assembler and Fitter?

Benefits of working as a Progressive Assembler and Fitter include competitive salaries, opportunities for career advancement, and the satisfaction of working in a challenging and rewarding field.

What are the challenges of working as a Progressive Assembler and Fitter?

Challenges of working as a Progressive Assembler and Fitter include working in a fast-paced and demanding environment, meeting tight deadlines, and working with complex machinery.