Are you a seasoned Pulp Bleacher seeking a new career path? Discover our professionally built Pulp Bleacher Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

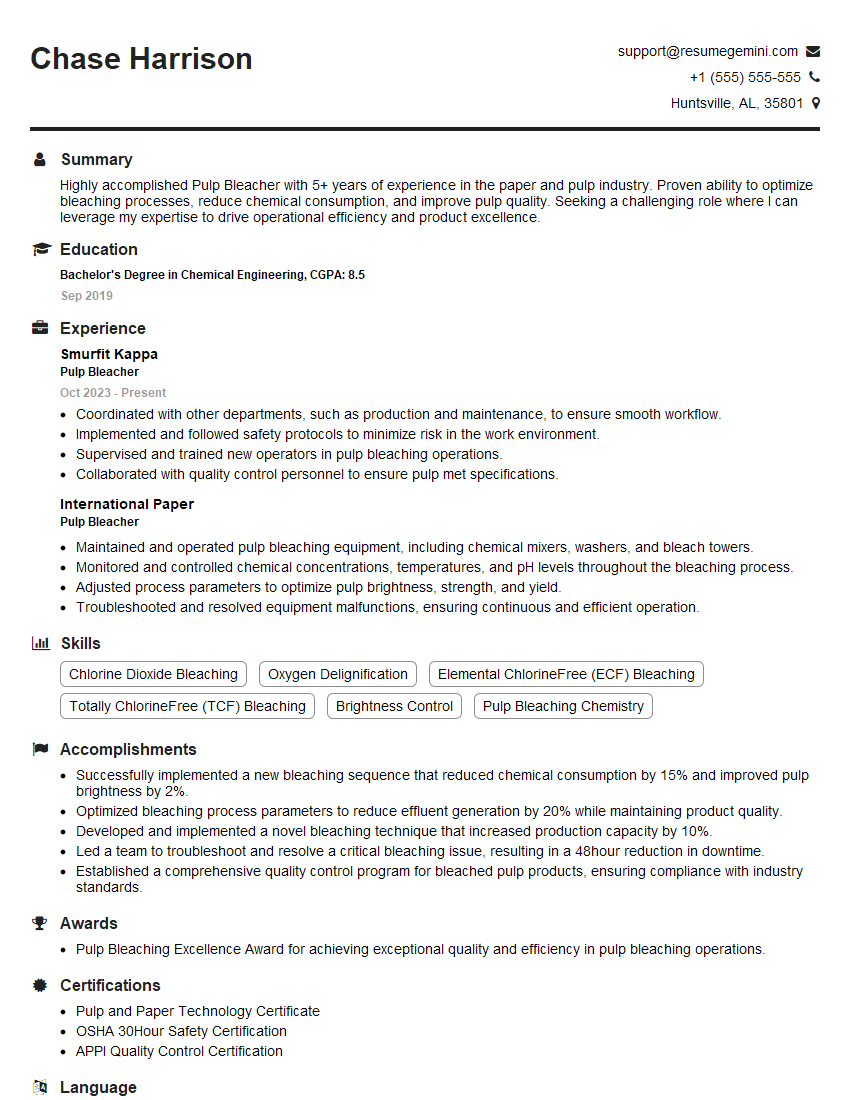

Chase Harrison

Pulp Bleacher

Summary

Highly accomplished Pulp Bleacher with 5+ years of experience in the paper and pulp industry. Proven ability to optimize bleaching processes, reduce chemical consumption, and improve pulp quality. Seeking a challenging role where I can leverage my expertise to drive operational efficiency and product excellence.

Education

Bachelor’s Degree in Chemical Engineering

September 2019

Skills

- Chlorine Dioxide Bleaching

- Oxygen Delignification

- Elemental ChlorineFree (ECF) Bleaching

- Totally ChlorineFree (TCF) Bleaching

- Brightness Control

- Pulp Bleaching Chemistry

Work Experience

Pulp Bleacher

- Coordinated with other departments, such as production and maintenance, to ensure smooth workflow.

- Implemented and followed safety protocols to minimize risk in the work environment.

- Supervised and trained new operators in pulp bleaching operations.

- Collaborated with quality control personnel to ensure pulp met specifications.

Pulp Bleacher

- Maintained and operated pulp bleaching equipment, including chemical mixers, washers, and bleach towers.

- Monitored and controlled chemical concentrations, temperatures, and pH levels throughout the bleaching process.

- Adjusted process parameters to optimize pulp brightness, strength, and yield.

- Troubleshooted and resolved equipment malfunctions, ensuring continuous and efficient operation.

Accomplishments

- Successfully implemented a new bleaching sequence that reduced chemical consumption by 15% and improved pulp brightness by 2%.

- Optimized bleaching process parameters to reduce effluent generation by 20% while maintaining product quality.

- Developed and implemented a novel bleaching technique that increased production capacity by 10%.

- Led a team to troubleshoot and resolve a critical bleaching issue, resulting in a 48hour reduction in downtime.

- Established a comprehensive quality control program for bleached pulp products, ensuring compliance with industry standards.

Awards

- Pulp Bleaching Excellence Award for achieving exceptional quality and efficiency in pulp bleaching operations.

Certificates

- Pulp and Paper Technology Certificate

- OSHA 30Hour Safety Certification

- APPI Quality Control Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Pulp Bleacher

- Highlight your technical expertise in pulp bleaching chemistry, including chlorine dioxide bleaching, oxygen delignification, and elemental chlorine-free (ECF) and totally chlorine-free (TCF) bleaching.

- Showcase your problem-solving abilities and provide specific examples of how you have identified and resolved critical bleaching issues.

- Demonstrate your commitment to continuous improvement by describing how you have implemented innovative techniques and optimized processes to enhance operational efficiency.

- Quantify your accomplishments with specific metrics, such as reductions in chemical consumption, effluent generation, and downtime, to demonstrate the impact of your work.

- Tailor your resume to each specific job application, highlighting the skills and experience that are most relevant to the position.

Essential Experience Highlights for a Strong Pulp Bleacher Resume

- Optimized bleaching process parameters to significantly reduce chemical consumption and effluent generation while maintaining product quality.

- Developed and implemented innovative bleaching techniques to increase production capacity and enhance pulp brightness.

- Led troubleshooting efforts to resolve critical bleaching issues, resulting in reduced downtime and improved operational efficiency.

- Established a comprehensive quality control program to ensure compliance with industry standards and meet customer specifications.

- Collaborated with cross-functional teams to streamline operations, improve communication, and drive continuous improvement.

- Conducted research and stayed abreast of the latest advancements in pulp bleaching technology to optimize processes and achieve operational excellence.

- Trained and mentored junior staff, providing guidance and support to develop their skills and knowledge.

Frequently Asked Questions (FAQ’s) For Pulp Bleacher

What are the key responsibilities of a Pulp Bleacher?

The key responsibilities of a Pulp Bleacher include optimizing bleaching processes, reducing chemical consumption, improving pulp quality, troubleshooting bleaching issues, and ensuring compliance with industry standards.

What are the educational requirements for becoming a Pulp Bleacher?

A Bachelor’s Degree in Chemical Engineering or a related field is typically required to become a Pulp Bleacher.

What are the career prospects for Pulp Bleachers?

Pulp Bleachers can advance to roles such as Pulp Mill Superintendent, Production Manager, or Research and Development Manager.

What are the challenges faced by Pulp Bleachers?

Pulp Bleachers face challenges such as optimizing bleaching processes to meet environmental regulations, reducing chemical consumption to minimize costs, and improving pulp quality to meet customer specifications.

What are the key skills for a successful Pulp Bleacher?

Successful Pulp Bleachers possess strong technical skills in pulp bleaching chemistry, problem-solving abilities, a commitment to continuous improvement, and excellent communication and teamwork skills.

What are the major factors affecting the quality of bleached pulp?

The major factors affecting the quality of bleached pulp include the type of wood used, the bleaching sequence, the chemicals used, and the process conditions.

What are the environmental considerations in pulp bleaching?

Pulp bleaching involves the use of chemicals that can have environmental impacts, so Pulp Bleachers must consider factors such as effluent generation, air emissions, and waste management.

What are the latest advancements in pulp bleaching technology?

The latest advancements in pulp bleaching technology include the use of oxygen delignification, elemental chlorine-free (ECF) and totally chlorine-free (TCF) bleaching, and closed-loop bleaching systems.