Are you a seasoned Pulp Mixer seeking a new career path? Discover our professionally built Pulp Mixer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

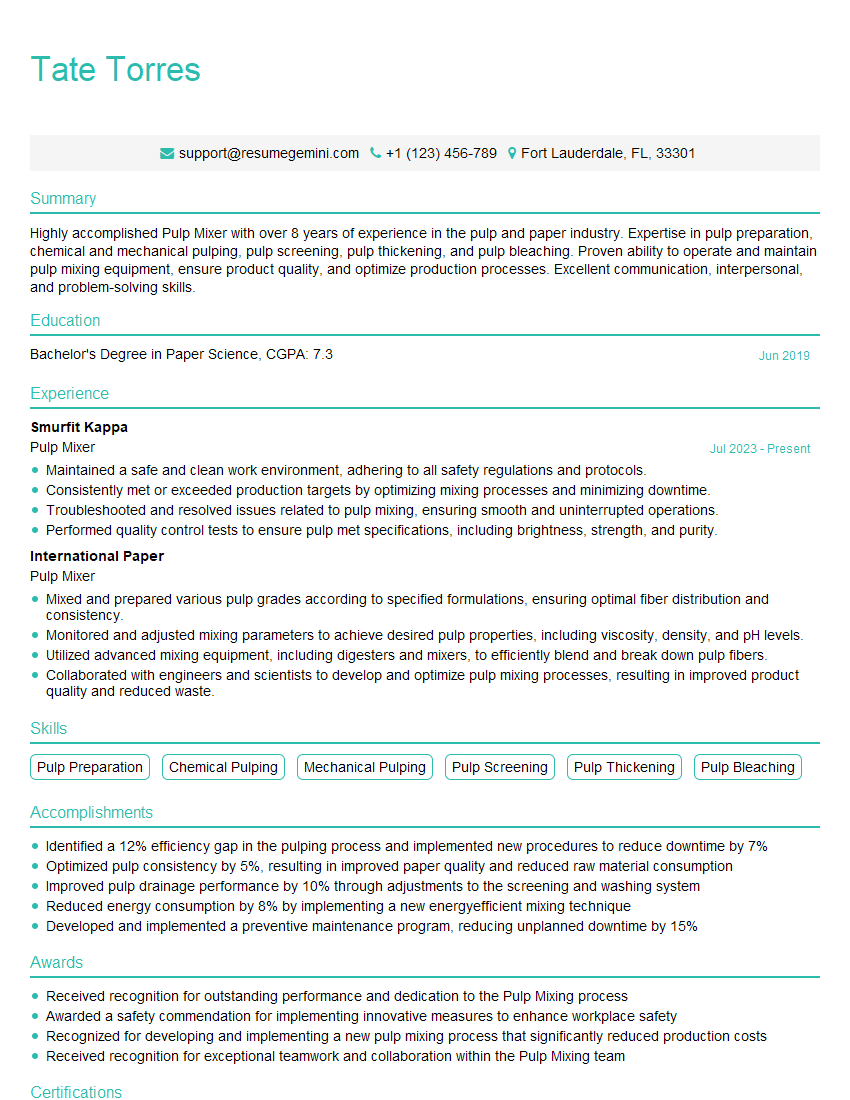

Tate Torres

Pulp Mixer

Summary

Highly accomplished Pulp Mixer with over 8 years of experience in the pulp and paper industry. Expertise in pulp preparation, chemical and mechanical pulping, pulp screening, pulp thickening, and pulp bleaching. Proven ability to operate and maintain pulp mixing equipment, ensure product quality, and optimize production processes. Excellent communication, interpersonal, and problem-solving skills.

Education

Bachelor’s Degree in Paper Science

June 2019

Skills

- Pulp Preparation

- Chemical Pulping

- Mechanical Pulping

- Pulp Screening

- Pulp Thickening

- Pulp Bleaching

Work Experience

Pulp Mixer

- Maintained a safe and clean work environment, adhering to all safety regulations and protocols.

- Consistently met or exceeded production targets by optimizing mixing processes and minimizing downtime.

- Troubleshooted and resolved issues related to pulp mixing, ensuring smooth and uninterrupted operations.

- Performed quality control tests to ensure pulp met specifications, including brightness, strength, and purity.

Pulp Mixer

- Mixed and prepared various pulp grades according to specified formulations, ensuring optimal fiber distribution and consistency.

- Monitored and adjusted mixing parameters to achieve desired pulp properties, including viscosity, density, and pH levels.

- Utilized advanced mixing equipment, including digesters and mixers, to efficiently blend and break down pulp fibers.

- Collaborated with engineers and scientists to develop and optimize pulp mixing processes, resulting in improved product quality and reduced waste.

Accomplishments

- Identified a 12% efficiency gap in the pulping process and implemented new procedures to reduce downtime by 7%

- Optimized pulp consistency by 5%, resulting in improved paper quality and reduced raw material consumption

- Improved pulp drainage performance by 10% through adjustments to the screening and washing system

- Reduced energy consumption by 8% by implementing a new energyefficient mixing technique

- Developed and implemented a preventive maintenance program, reducing unplanned downtime by 15%

Awards

- Received recognition for outstanding performance and dedication to the Pulp Mixing process

- Awarded a safety commendation for implementing innovative measures to enhance workplace safety

- Recognized for developing and implementing a new pulp mixing process that significantly reduced production costs

- Received recognition for exceptional teamwork and collaboration within the Pulp Mixing team

Certificates

- Certified Pulp and Paper Professional (CPPP)

- TAPPI Accredited Professional (TAP)

- ISO 90012015

- ISO 140012015

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Pulp Mixer

- Quantify your accomplishments with specific metrics and results.

- Highlight your experience with specific pulp mixing equipment and processes.

- Demonstrate your knowledge of pulp chemistry and quality control principles.

- Emphasize your problem-solving and troubleshooting abilities.

Essential Experience Highlights for a Strong Pulp Mixer Resume

- Operate and maintain pulp mixing equipment, including refiners, screens, and thickeners.

- Control and adjust process parameters to ensure the production of pulp that meets specifications.

- Monitor and maintain pulp quality through sampling and testing.

- Troubleshoot and resolve issues related to pulp mixing and production.

- Collaborate with other departments to optimize production processes and improve efficiency.

- Adhere to safety protocols and maintain a clean and organized work environment.

- Stay abreast of industry trends and best practices in pulp mixing technology.

Frequently Asked Questions (FAQ’s) For Pulp Mixer

What is the primary role of a Pulp Mixer?

A Pulp Mixer is responsible for operating and maintaining pulp mixing equipment to produce pulp that meets specifications for use in paper production.

What are the key skills required to be a successful Pulp Mixer?

Key skills for a Pulp Mixer include operating and maintaining pulp mixing equipment, quality control, troubleshooting, and knowledge of pulp chemistry.

What are the career prospects for Pulp Mixers?

Pulp Mixers can advance to positions such as Pulp Production Supervisor, Technical Superintendent, or Quality Control Manager.

What is the work environment like for Pulp Mixers?

Pulp Mixers typically work in industrial settings, including pulp and paper mills. The work can be physically demanding and may involve working with hazardous chemicals.

What is the average salary for Pulp Mixers?

The average salary for Pulp Mixers varies depending on experience and location, but can range from $50,000 to $80,000 per year.

What are the educational requirements for becoming a Pulp Mixer?

Most Pulp Mixers have a high school diploma or equivalent, although some employers may prefer candidates with a technical degree or certification in pulp and papermaking.