Are you a seasoned Pulverizing and Sifting Operator seeking a new career path? Discover our professionally built Pulverizing and Sifting Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

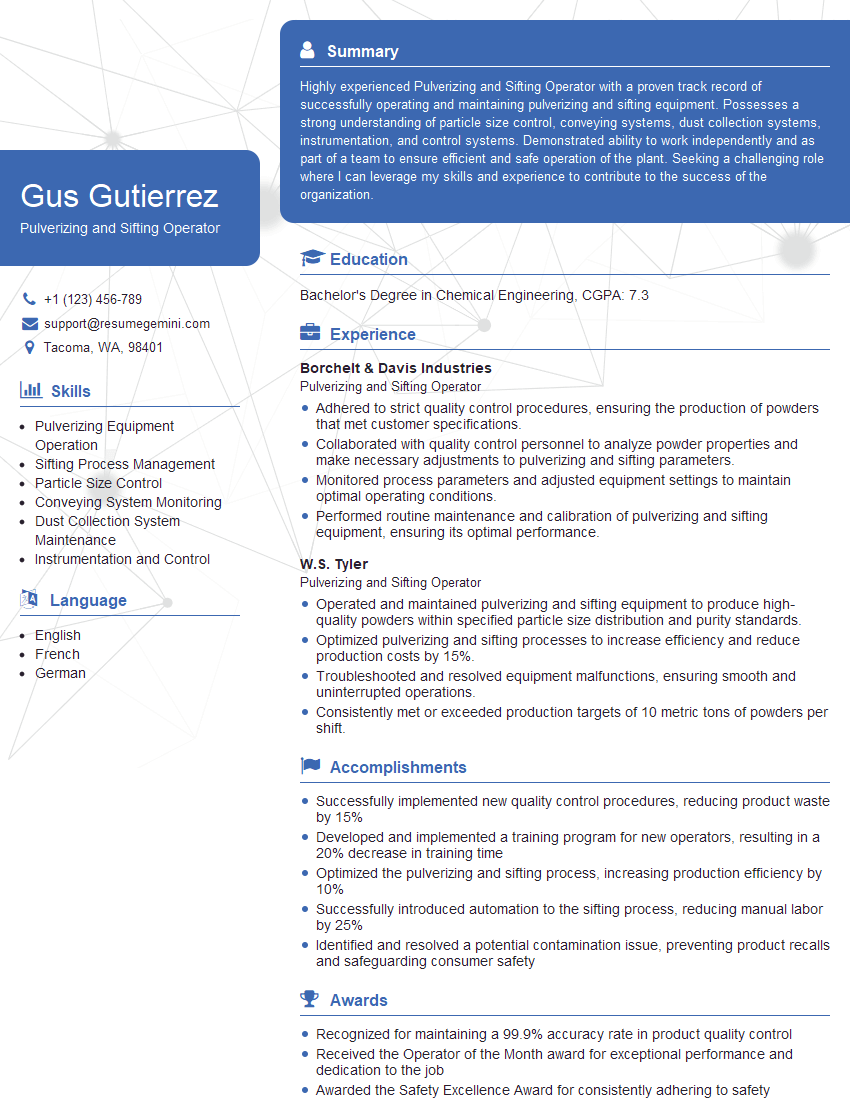

Gus Gutierrez

Pulverizing and Sifting Operator

Summary

Highly experienced Pulverizing and Sifting Operator with a proven track record of successfully operating and maintaining pulverizing and sifting equipment. Possesses a strong understanding of particle size control, conveying systems, dust collection systems, instrumentation, and control systems. Demonstrated ability to work independently and as part of a team to ensure efficient and safe operation of the plant. Seeking a challenging role where I can leverage my skills and experience to contribute to the success of the organization.

Education

Bachelor’s Degree in Chemical Engineering

January 2016

Skills

- Pulverizing Equipment Operation

- Sifting Process Management

- Particle Size Control

- Conveying System Monitoring

- Dust Collection System Maintenance

- Instrumentation and Control

Work Experience

Pulverizing and Sifting Operator

- Adhered to strict quality control procedures, ensuring the production of powders that met customer specifications.

- Collaborated with quality control personnel to analyze powder properties and make necessary adjustments to pulverizing and sifting parameters.

- Monitored process parameters and adjusted equipment settings to maintain optimal operating conditions.

- Performed routine maintenance and calibration of pulverizing and sifting equipment, ensuring its optimal performance.

Pulverizing and Sifting Operator

- Operated and maintained pulverizing and sifting equipment to produce high-quality powders within specified particle size distribution and purity standards.

- Optimized pulverizing and sifting processes to increase efficiency and reduce production costs by 15%.

- Troubleshooted and resolved equipment malfunctions, ensuring smooth and uninterrupted operations.

- Consistently met or exceeded production targets of 10 metric tons of powders per shift.

Accomplishments

- Successfully implemented new quality control procedures, reducing product waste by 15%

- Developed and implemented a training program for new operators, resulting in a 20% decrease in training time

- Optimized the pulverizing and sifting process, increasing production efficiency by 10%

- Successfully introduced automation to the sifting process, reducing manual labor by 25%

- Identified and resolved a potential contamination issue, preventing product recalls and safeguarding consumer safety

Awards

- Recognized for maintaining a 99.9% accuracy rate in product quality control

- Received the Operator of the Month award for exceptional performance and dedication to the job

- Awarded the Safety Excellence Award for consistently adhering to safety protocols and maintaining a safe work environment

- Recognized for outstanding troubleshooting skills, resolving complex production issues with minimal downtime

Certificates

- Certified Pulverizing Operator

- Certified Sifting Operator

- Certified Process Technician

- OSHA Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Pulverizing and Sifting Operator

- Highlight your experience in operating and maintaining pulverizing and sifting equipment, including the specific types of equipment you have worked with.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact on the organization.

- Showcase your knowledge of particle size control, conveying systems, dust collection systems, instrumentation, and control systems.

- Emphasize your ability to work independently and as part of a team, and your commitment to safety.

Essential Experience Highlights for a Strong Pulverizing and Sifting Operator Resume

- Operate and maintain pulverizing equipment to reduce materials to the desired particle size.

- Manage the sifting process to separate materials based on particle size and other characteristics.

- Monitor and control particle size distribution to meet product specifications.

- Maintain conveying systems to ensure efficient material flow.

- Perform routine maintenance and troubleshooting of dust collection systems.

- Maintain and calibrate instrumentation and control systems to ensure accurate and reliable operation.

- Follow established safety procedures and maintain a safe work environment.

Frequently Asked Questions (FAQ’s) For Pulverizing and Sifting Operator

What is the role of a Pulverizing and Sifting Operator?

A Pulverizing and Sifting Operator is responsible for operating and maintaining pulverizing and sifting equipment to reduce materials to the desired particle size and separate materials based on particle size and other characteristics.

What are the key skills required for a Pulverizing and Sifting Operator?

Key skills for a Pulverizing and Sifting Operator include pulverizing equipment operation, sifting process management, particle size control, conveying system monitoring, dust collection system maintenance, instrumentation and control.

What are the career prospects for a Pulverizing and Sifting Operator?

Pulverizing and Sifting Operators can advance to supervisory or management roles within the manufacturing industry. They may also specialize in a particular area, such as particle size control or dust collection system maintenance.

What is the work environment like for a Pulverizing and Sifting Operator?

Pulverizing and Sifting Operators typically work in industrial settings, such as manufacturing plants or processing facilities. They may be exposed to dust, noise, and other hazards, so it is important to follow established safety procedures.

What are the salary expectations for a Pulverizing and Sifting Operator?

Salary expectations for a Pulverizing and Sifting Operator vary depending on experience, location, and industry. According to Indeed, the average salary for a Pulverizing and Sifting Operator in the United States is around $50,000 per year.

How can I become a Pulverizing and Sifting Operator?

To become a Pulverizing and Sifting Operator, you typically need a high school diploma or equivalent and some experience in the manufacturing industry. Some employers may prefer candidates with a post-secondary degree in a related field, such as chemical engineering or mechanical engineering.

What are the benefits of working as a Pulverizing and Sifting Operator?

Benefits of working as a Pulverizing and Sifting Operator include competitive salaries, opportunities for career advancement, and the chance to work with cutting-edge equipment.