Are you a seasoned Pump Technician seeking a new career path? Discover our professionally built Pump Technician Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

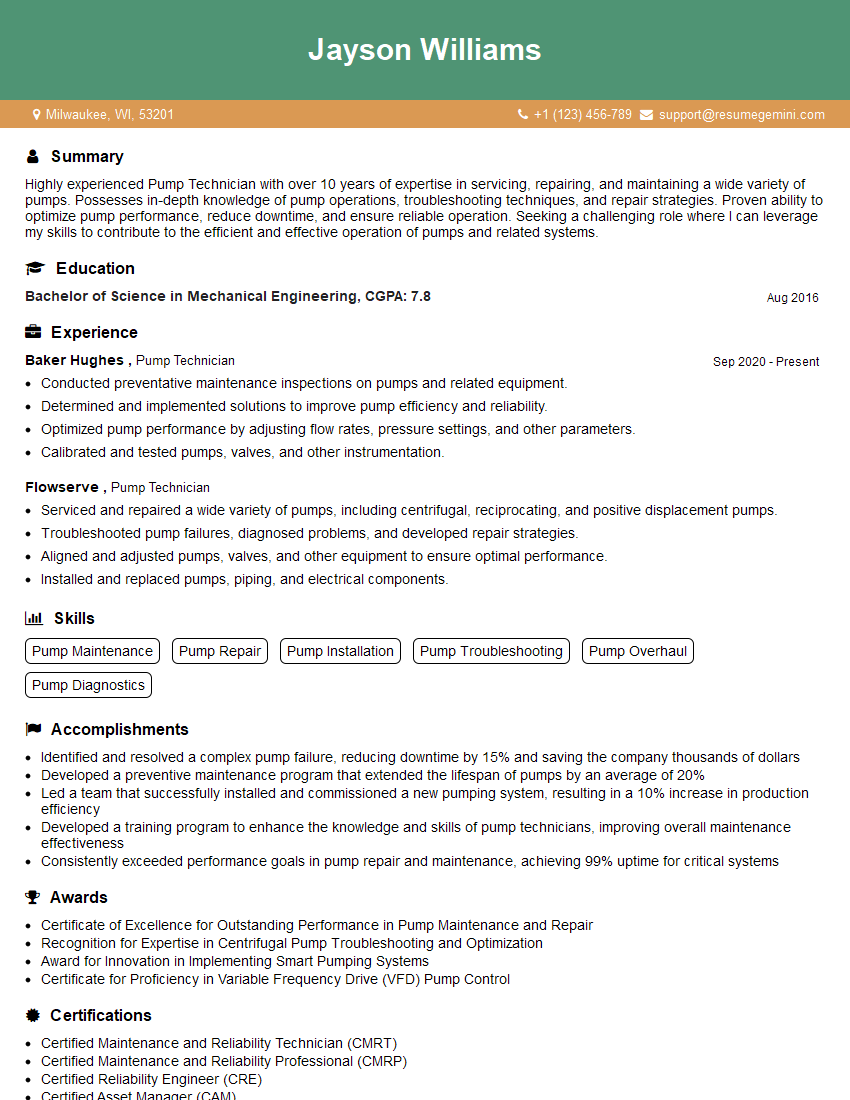

Jayson Williams

Pump Technician

Summary

Highly experienced Pump Technician with over 10 years of expertise in servicing, repairing, and maintaining a wide variety of pumps. Possesses in-depth knowledge of pump operations, troubleshooting techniques, and repair strategies. Proven ability to optimize pump performance, reduce downtime, and ensure reliable operation. Seeking a challenging role where I can leverage my skills to contribute to the efficient and effective operation of pumps and related systems.

Education

Bachelor of Science in Mechanical Engineering

August 2016

Skills

- Pump Maintenance

- Pump Repair

- Pump Installation

- Pump Troubleshooting

- Pump Overhaul

- Pump Diagnostics

Work Experience

Pump Technician

- Conducted preventative maintenance inspections on pumps and related equipment.

- Determined and implemented solutions to improve pump efficiency and reliability.

- Optimized pump performance by adjusting flow rates, pressure settings, and other parameters.

- Calibrated and tested pumps, valves, and other instrumentation.

Pump Technician

- Serviced and repaired a wide variety of pumps, including centrifugal, reciprocating, and positive displacement pumps.

- Troubleshooted pump failures, diagnosed problems, and developed repair strategies.

- Aligned and adjusted pumps, valves, and other equipment to ensure optimal performance.

- Installed and replaced pumps, piping, and electrical components.

Accomplishments

- Identified and resolved a complex pump failure, reducing downtime by 15% and saving the company thousands of dollars

- Developed a preventive maintenance program that extended the lifespan of pumps by an average of 20%

- Led a team that successfully installed and commissioned a new pumping system, resulting in a 10% increase in production efficiency

- Developed a training program to enhance the knowledge and skills of pump technicians, improving overall maintenance effectiveness

- Consistently exceeded performance goals in pump repair and maintenance, achieving 99% uptime for critical systems

Awards

- Certificate of Excellence for Outstanding Performance in Pump Maintenance and Repair

- Recognition for Expertise in Centrifugal Pump Troubleshooting and Optimization

- Award for Innovation in Implementing Smart Pumping Systems

- Certificate for Proficiency in Variable Frequency Drive (VFD) Pump Control

Certificates

- Certified Maintenance and Reliability Technician (CMRT)

- Certified Maintenance and Reliability Professional (CMRP)

- Certified Reliability Engineer (CRE)

- Certified Asset Manager (CAM)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Pump Technician

- Highlight your technical skills and experience in pump maintenance, repair, and troubleshooting.

- Showcase your knowledge of pump types, operations, and industry best practices.

- Emphasize your ability to work independently and as part of a team in a fast-paced environment.

- Quantify your accomplishments whenever possible to demonstrate the impact of your work.

Essential Experience Highlights for a Strong Pump Technician Resume

- Serviced and repaired various types of pumps, including centrifugal, reciprocating, and positive displacement pumps.

- Troubleshooted pump failures, accurately diagnosed problems, and implemented effective repair solutions.

- Aligned and adjusted pumps, valves, and other equipment to ensure optimal performance and efficiency.

- Installed and replaced pumps, piping, and electrical components to maintain system functionality.

- Conducted preventative maintenance inspections on pumps and associated equipment to identify potential issues.

- Determined and implemented solutions to improve pump efficiency, reliability, and lifespan.

- Optimized pump performance by adjusting flow rates, pressure settings, and other parameters to enhance system efficiency.

Frequently Asked Questions (FAQ’s) For Pump Technician

What are the key responsibilities of a Pump Technician?

Pump Technicians are responsible for maintaining, repairing, and installing pumps and associated systems. They troubleshoot pump failures, align and adjust equipment, conduct preventative maintenance inspections, and implement solutions to improve pump efficiency and reliability.

What are the qualifications required to become a Pump Technician?

Typically, a high school diploma or equivalent is required to become a Pump Technician. However, some employers may prefer candidates with a Bachelor’s degree in Mechanical Engineering or a related field.

What are the career prospects for a Pump Technician?

Pump Technicians can advance their careers by gaining experience and certifications. They can become Lead Pump Technicians, Supervisors, or Managers. Some may also specialize in a particular type of pump or industry.

What are the key skills and qualities of a successful Pump Technician?

Successful Pump Technicians possess strong technical skills, including the ability to troubleshoot and repair pumps and related equipment. They are also proficient in reading and interpreting technical drawings and schematics. Additionally, they have excellent communication and interpersonal skills.

What are the common work environments for a Pump Technician?

Pump Technicians typically work in industrial or manufacturing settings, where pumps are used for various applications. They may work indoors or outdoors, and may be required to work in confined spaces or at heights.

What are the safety precautions that Pump Technicians should take?

Pump Technicians should always follow proper safety protocols when working with pumps and related equipment. They should wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and earplugs, and be aware of potential hazards such as electrical shock, rotating machinery, and high-pressure systems.

What are the professional development opportunities for Pump Technicians?

Pump Technicians can enhance their skills and knowledge by attending training programs, workshops, and conferences. They can also obtain certifications from organizations such as the Hydraulic Institute or the National Institute for Certification in Engineering Technologies (NICET).