Are you a seasoned Quality Director seeking a new career path? Discover our professionally built Quality Director Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

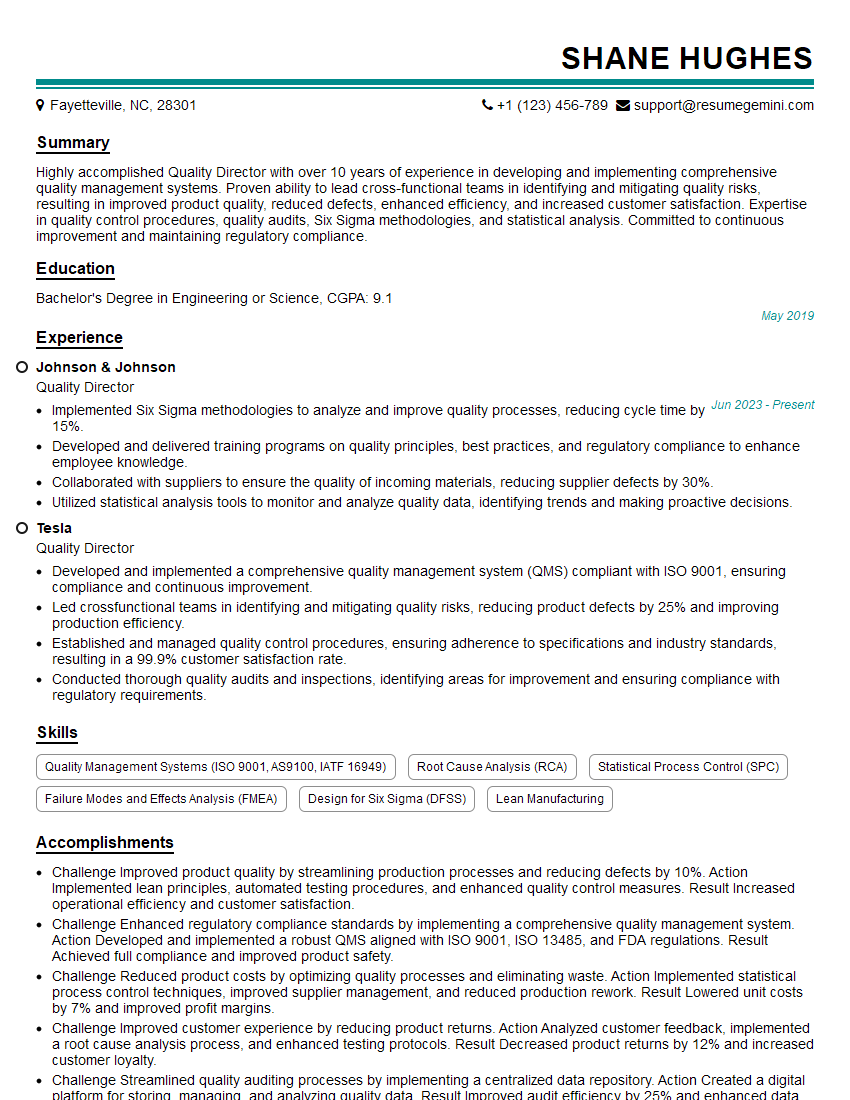

Shane Hughes

Quality Director

Summary

Highly accomplished Quality Director with over 10 years of experience in developing and implementing comprehensive quality management systems. Proven ability to lead cross-functional teams in identifying and mitigating quality risks, resulting in improved product quality, reduced defects, enhanced efficiency, and increased customer satisfaction. Expertise in quality control procedures, quality audits, Six Sigma methodologies, and statistical analysis. Committed to continuous improvement and maintaining regulatory compliance.

Education

Bachelor’s Degree in Engineering or Science

May 2019

Skills

- Quality Management Systems (ISO 9001, AS9100, IATF 16949)

- Root Cause Analysis (RCA)

- Statistical Process Control (SPC)

- Failure Modes and Effects Analysis (FMEA)

- Design for Six Sigma (DFSS)

- Lean Manufacturing

Work Experience

Quality Director

- Implemented Six Sigma methodologies to analyze and improve quality processes, reducing cycle time by 15%.

- Developed and delivered training programs on quality principles, best practices, and regulatory compliance to enhance employee knowledge.

- Collaborated with suppliers to ensure the quality of incoming materials, reducing supplier defects by 30%.

- Utilized statistical analysis tools to monitor and analyze quality data, identifying trends and making proactive decisions.

Quality Director

- Developed and implemented a comprehensive quality management system (QMS) compliant with ISO 9001, ensuring compliance and continuous improvement.

- Led crossfunctional teams in identifying and mitigating quality risks, reducing product defects by 25% and improving production efficiency.

- Established and managed quality control procedures, ensuring adherence to specifications and industry standards, resulting in a 99.9% customer satisfaction rate.

- Conducted thorough quality audits and inspections, identifying areas for improvement and ensuring compliance with regulatory requirements.

Accomplishments

- Challenge Improved product quality by streamlining production processes and reducing defects by 10%. Action Implemented lean principles, automated testing procedures, and enhanced quality control measures. Result Increased operational efficiency and customer satisfaction.

- Challenge Enhanced regulatory compliance standards by implementing a comprehensive quality management system. Action Developed and implemented a robust QMS aligned with ISO 9001, ISO 13485, and FDA regulations. Result Achieved full compliance and improved product safety.

- Challenge Reduced product costs by optimizing quality processes and eliminating waste. Action Implemented statistical process control techniques, improved supplier management, and reduced production rework. Result Lowered unit costs by 7% and improved profit margins.

- Challenge Improved customer experience by reducing product returns. Action Analyzed customer feedback, implemented a root cause analysis process, and enhanced testing protocols. Result Decreased product returns by 12% and increased customer loyalty.

- Challenge Streamlined quality auditing processes by implementing a centralized data repository. Action Created a digital platform for storing, managing, and analyzing quality data. Result Improved audit efficiency by 25% and enhanced data accessibility.

Awards

- Recognized with the Quality Excellence Award for implementing innovative quality initiatives that reduced product defects by 20%.

- Received the Six Sigma Black Belt Certification for expertise in applying Six Sigma principles to improve quality and efficiency.

- Awarded the Quality Leadership Award for driving continuous improvement programs that resulted in a 15% increase in customer satisfaction.

- Honored with the Quality Pioneer Award for developing and implementing a predictive analytics tool that reduced product recalls by 30%.

Certificates

- Certified Quality Engineer (CQE)

- Certified Manager of Quality / Organizational Excellence (CMQ/OE)

- Certified Six Sigma Black Belt (CSSBB)

- Certified Quality Auditor (CQA)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Quality Director

- Quantify your accomplishments and provide specific examples of how your contributions have impacted the organization’s quality performance.

- Highlight your expertise in quality management systems and industry standards, such as ISO 9001, AS9100, and IATF 16949.

- Demonstrate your proficiency in statistical analysis tools and methodologies, such as Six Sigma and SPC, and how you have used them to improve quality processes.

- Showcase your ability to collaborate effectively with cross-functional teams and build strong relationships with suppliers to ensure the highest quality standards throughout the supply chain.

Essential Experience Highlights for a Strong Quality Director Resume

- Develop and implement comprehensive quality management systems (QMS) compliant with ISO 9001, AS9100, IATF 16949, and other industry standards.

- Lead cross-functional teams in identifying and mitigating quality risks, implementing corrective actions, and driving continuous improvement initiatives.

- Establish and manage quality control procedures to ensure adherence to specifications and industry standards, resulting in high product quality and customer satisfaction.

- Conduct thorough quality audits and inspections to assess compliance, identify areas for improvement, and recommend corrective actions.

- Implement Six Sigma methodologies to analyze and improve quality processes, reducing cycle time and improving efficiency.

- Develop and deliver training programs on quality principles, best practices, and regulatory compliance to enhance employee knowledge and skills.

- Collaborate with suppliers to ensure the quality of incoming materials and reduce supplier defects through robust supplier management practices.

Frequently Asked Questions (FAQ’s) For Quality Director

What are the key responsibilities of a Quality Director?

The key responsibilities of a Quality Director include developing and implementing quality management systems, leading cross-functional teams in identifying and mitigating quality risks, establishing and managing quality control procedures, conducting quality audits and inspections, implementing Six Sigma methodologies, developing and delivering training programs on quality principles, and collaborating with suppliers to ensure the quality of incoming materials.

What are the essential skills and qualifications for a Quality Director?

Essential skills and qualifications for a Quality Director include expertise in quality management systems, such as ISO 9001, AS9100, and IATF 16949, proficiency in statistical analysis tools and methodologies, such as Six Sigma and SPC, strong leadership and communication skills, and the ability to collaborate effectively with cross-functional teams and build relationships with suppliers.

What are the career prospects for a Quality Director?

Quality Directors have excellent career prospects, with opportunities for advancement within the quality management field, such as Senior Quality Director, Vice President of Quality, or Chief Quality Officer. They can also move into general management roles, such as Operations Manager, General Manager, or CEO.

What are the salary expectations for a Quality Director?

Salary expectations for a Quality Director vary depending on experience, qualifications, industry, and location. According to Salary.com, the average salary for a Quality Director in the United States is $115,000 per year.

What are the challenges faced by Quality Directors?

Quality Directors face several challenges, including ensuring compliance with regulatory standards, meeting customer expectations, managing quality risks, and driving continuous improvement. They must also stay up-to-date on the latest quality management trends and technologies to maintain a competitive edge.

What are the qualities of a successful Quality Director?

Successful Quality Directors are passionate about quality, have a strong attention to detail, and are committed to continuous improvement. They are also effective leaders, communicators, and problem solvers, and they possess the ability to build strong relationships with cross-functional teams and suppliers.