Are you a seasoned Quartz Cutter seeking a new career path? Discover our professionally built Quartz Cutter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

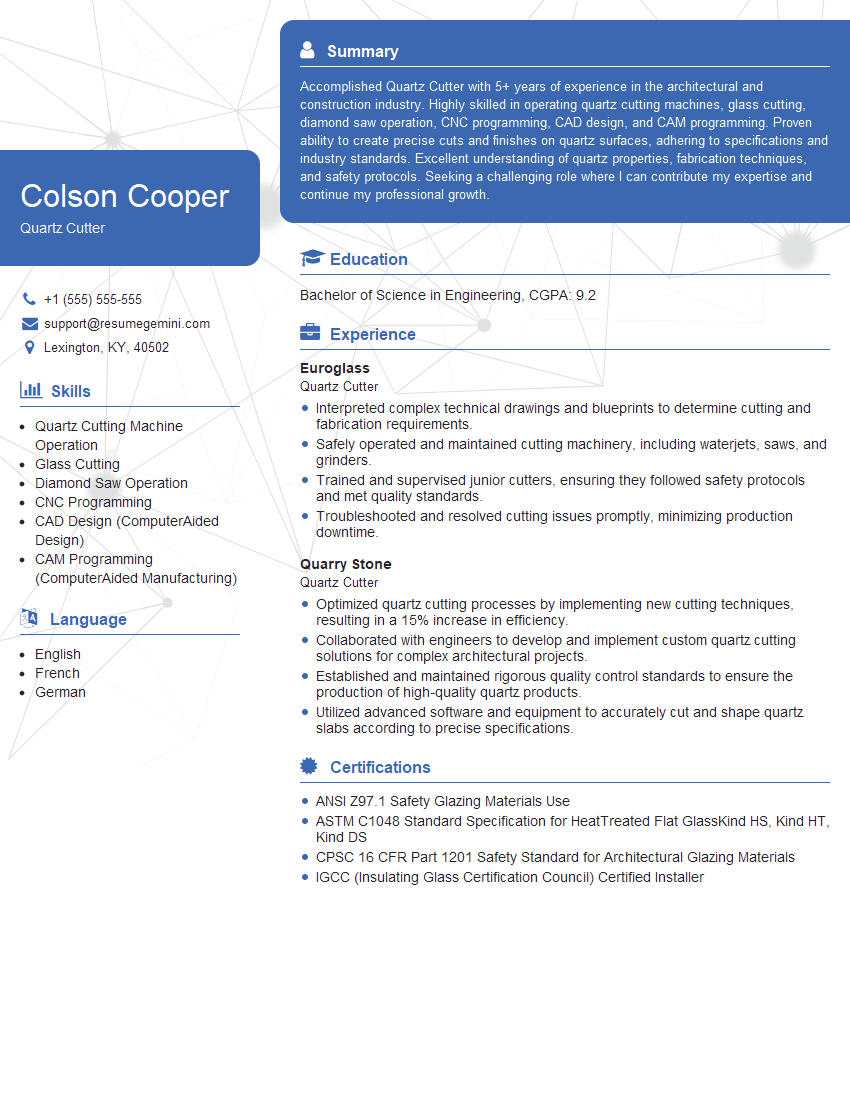

Colson Cooper

Quartz Cutter

Summary

Accomplished Quartz Cutter with 5+ years of experience in the architectural and construction industry. Highly skilled in operating quartz cutting machines, glass cutting, diamond saw operation, CNC programming, CAD design, and CAM programming. Proven ability to create precise cuts and finishes on quartz surfaces, adhering to specifications and industry standards. Excellent understanding of quartz properties, fabrication techniques, and safety protocols. Seeking a challenging role where I can contribute my expertise and continue my professional growth.

Education

Bachelor of Science in Engineering

December 2016

Skills

- Quartz Cutting Machine Operation

- Glass Cutting

- Diamond Saw Operation

- CNC Programming

- CAD Design (ComputerAided Design)

- CAM Programming (ComputerAided Manufacturing)

Work Experience

Quartz Cutter

- Interpreted complex technical drawings and blueprints to determine cutting and fabrication requirements.

- Safely operated and maintained cutting machinery, including waterjets, saws, and grinders.

- Trained and supervised junior cutters, ensuring they followed safety protocols and met quality standards.

- Troubleshooted and resolved cutting issues promptly, minimizing production downtime.

Quartz Cutter

- Optimized quartz cutting processes by implementing new cutting techniques, resulting in a 15% increase in efficiency.

- Collaborated with engineers to develop and implement custom quartz cutting solutions for complex architectural projects.

- Established and maintained rigorous quality control standards to ensure the production of high-quality quartz products.

- Utilized advanced software and equipment to accurately cut and shape quartz slabs according to precise specifications.

Certificates

- ANSI Z97.1 Safety Glazing Materials Use

- ASTM C1048 Standard Specification for HeatTreated Flat GlassKind HS, Kind HT, Kind DS

- CPSC 16 CFR Part 1201 Safety Standard for Architectural Glazing Materials

- IGCC (Insulating Glass Certification Council) Certified Installer

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Quartz Cutter

Quantify your accomplishments

: Use specific numbers and metrics to demonstrate your impact in previous roles.Highlight your technical skills

: Emphasize your proficiency in quartz cutting machines, CNC programming, and CAD design.Showcase your attention to detail

: Describe your ability to produce accurate and precise cuts and finishes.Tailor your resume to the job description

: Address the specific requirements and keywords mentioned in the job posting.

Essential Experience Highlights for a Strong Quartz Cutter Resume

- Operate quartz cutting machines, including CNC saws and waterjets, to cut and shape quartz surfaces according to specifications.

- Interpret blueprints, design drawings, and work orders to determine cutting parameters and ensure accuracy.

- Calculate measurements, angles, and dimensions using computer-aided design (CAD) software.

- Program and operate CNC cutting machines to achieve precise cuts and finishes.

- Inspect finished quartz surfaces for quality, accuracy, and adherence to specifications.

- Maintain and calibrate quartz cutting equipment to ensure optimal performance and safety.

- Follow established safety protocols and wear appropriate personal protective equipment (PPE) while operating machinery.

Frequently Asked Questions (FAQ’s) For Quartz Cutter

What are the essential skills for a Quartz Cutter?

Essential skills for a Quartz Cutter include proficiency in operating quartz cutting machines, glass cutting, diamond saw operation, CNC programming, CAD design, and CAM programming.

What is the primary role of a Quartz Cutter?

The primary role of a Quartz Cutter is to cut and shape quartz surfaces according to design specifications and industry standards.

What qualifications are typically required for a Quartz Cutter?

Typically, a Quartz Cutter requires a high school diploma or equivalent, with or without additional training in fabrication or engineering.

What are the career prospects for a Quartz Cutter?

Quartz Cutters with experience and expertise can advance to supervisory roles, such as Fabrication Manager or Production Supervisor.

What is the average salary range for a Quartz Cutter?

The average salary range for a Quartz Cutter varies depending on experience, location, and company size. It typically falls between $35,000 to $60,000 per year.

What safety precautions should a Quartz Cutter follow?

Quartz Cutters must wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and hearing protection. They should also be trained in proper machine operation and safety protocols.

What are some common challenges faced by Quartz Cutters?

Common challenges faced by Quartz Cutters include working with heavy materials, adhering to precise specifications, and ensuring the safety of themselves and others.