Are you a seasoned Reaming Machine Operator for Plastic seeking a new career path? Discover our professionally built Reaming Machine Operator for Plastic Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

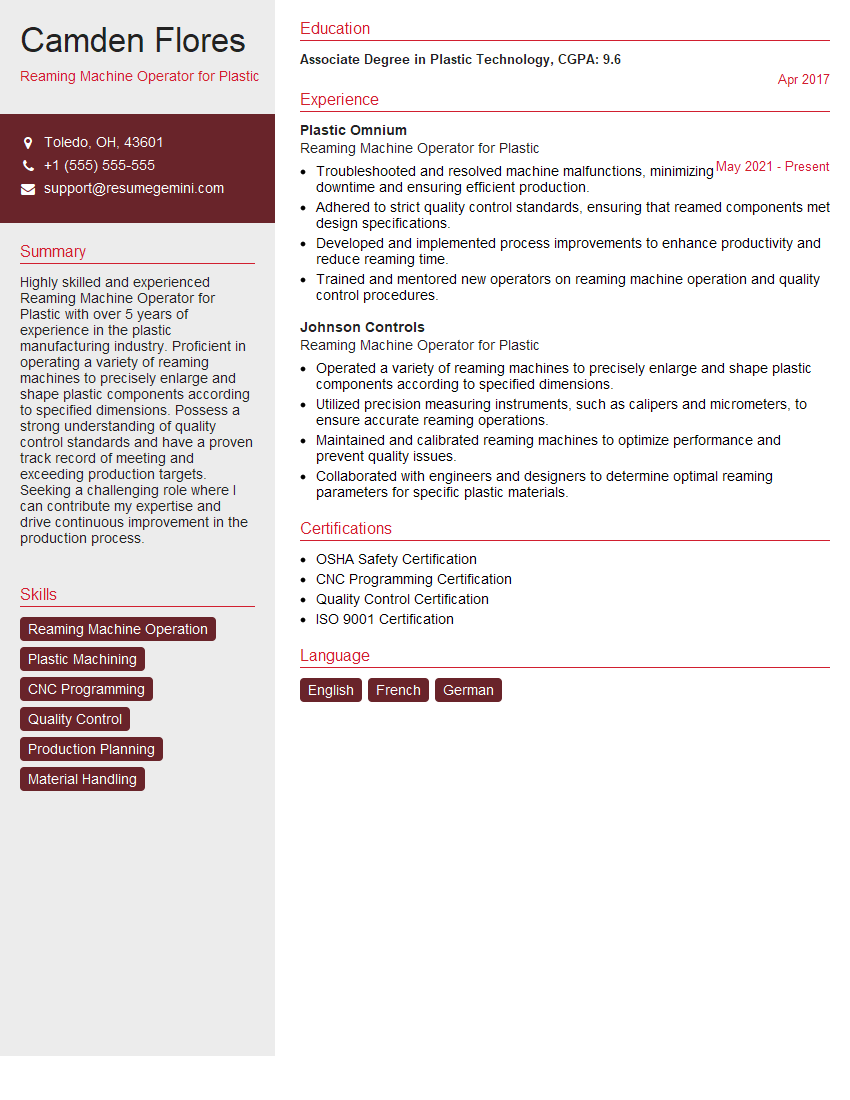

Camden Flores

Reaming Machine Operator for Plastic

Summary

Highly skilled and experienced Reaming Machine Operator for Plastic with over 5 years of experience in the plastic manufacturing industry. Proficient in operating a variety of reaming machines to precisely enlarge and shape plastic components according to specified dimensions. Possess a strong understanding of quality control standards and have a proven track record of meeting and exceeding production targets. Seeking a challenging role where I can contribute my expertise and drive continuous improvement in the production process.

Education

Associate Degree in Plastic Technology

April 2017

Skills

- Reaming Machine Operation

- Plastic Machining

- CNC Programming

- Quality Control

- Production Planning

- Material Handling

Work Experience

Reaming Machine Operator for Plastic

- Troubleshooted and resolved machine malfunctions, minimizing downtime and ensuring efficient production.

- Adhered to strict quality control standards, ensuring that reamed components met design specifications.

- Developed and implemented process improvements to enhance productivity and reduce reaming time.

- Trained and mentored new operators on reaming machine operation and quality control procedures.

Reaming Machine Operator for Plastic

- Operated a variety of reaming machines to precisely enlarge and shape plastic components according to specified dimensions.

- Utilized precision measuring instruments, such as calipers and micrometers, to ensure accurate reaming operations.

- Maintained and calibrated reaming machines to optimize performance and prevent quality issues.

- Collaborated with engineers and designers to determine optimal reaming parameters for specific plastic materials.

Certificates

- OSHA Safety Certification

- CNC Programming Certification

- Quality Control Certification

- ISO 9001 Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Reaming Machine Operator for Plastic

- Highlight your experience and skills in operating reaming machines for plastic.

- Quantify your accomplishments whenever possible, such as reducing downtime by a certain percentage.

- Demonstrate your commitment to quality by mentioning any certifications or training you have received.

- Network with other professionals in the industry to learn about new technologies and trends.

Essential Experience Highlights for a Strong Reaming Machine Operator for Plastic Resume

- Operate reaming machines to precisely enlarge and shape plastic components.

- Utilize precision measuring instruments to ensure accurate reaming operations.

- Maintain and calibrate reaming machines to optimize performance and prevent quality issues.

- Collaborate with engineers and designers to determine optimal reaming parameters for specific plastic materials.

- Troubleshoot and resolve machine malfunctions to minimize downtime.

- Adhere to strict quality control standards to ensure that reamed components meet design specifications.

Frequently Asked Questions (FAQ’s) For Reaming Machine Operator for Plastic

What is the role of a Reaming Machine Operator for Plastic?

A Reaming Machine Operator for Plastic is responsible for operating reaming machines to precisely enlarge and shape plastic components according to specified dimensions. They also maintain and calibrate reaming machines to ensure optimal performance and prevent quality issues.

What are the key skills required to be a successful Reaming Machine Operator for Plastic?

Key skills for a Reaming Machine Operator for Plastic include: operating reaming machines, plastic machining, CNC programming, quality control, production planning, and material handling.

What is the typical work environment for a Reaming Machine Operator for Plastic?

Reaming Machine Operators for Plastic typically work in a manufacturing environment, often in a production line setting. They may work with other operators, engineers, and quality control personnel.

What are the career prospects for a Reaming Machine Operator for Plastic?

With experience and additional training, Reaming Machine Operators for Plastic can advance to supervisory roles or become CNC programmers. They may also specialize in a particular area of plastic machining, such as mold making or prototyping.

What is the average salary for a Reaming Machine Operator for Plastic?

The average salary for a Reaming Machine Operator for Plastic varies depending on factors such as experience, location, and company size. According to Salary.com, the average salary for a Reaming Machine Operator for Plastic in the United States is $25.63 per hour.

What are the benefits of working as a Reaming Machine Operator for Plastic?

Benefits of working as a Reaming Machine Operator for Plastic include: job security, opportunities for advancement, and competitive pay.