Are you a seasoned Rebar Fabricator seeking a new career path? Discover our professionally built Rebar Fabricator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

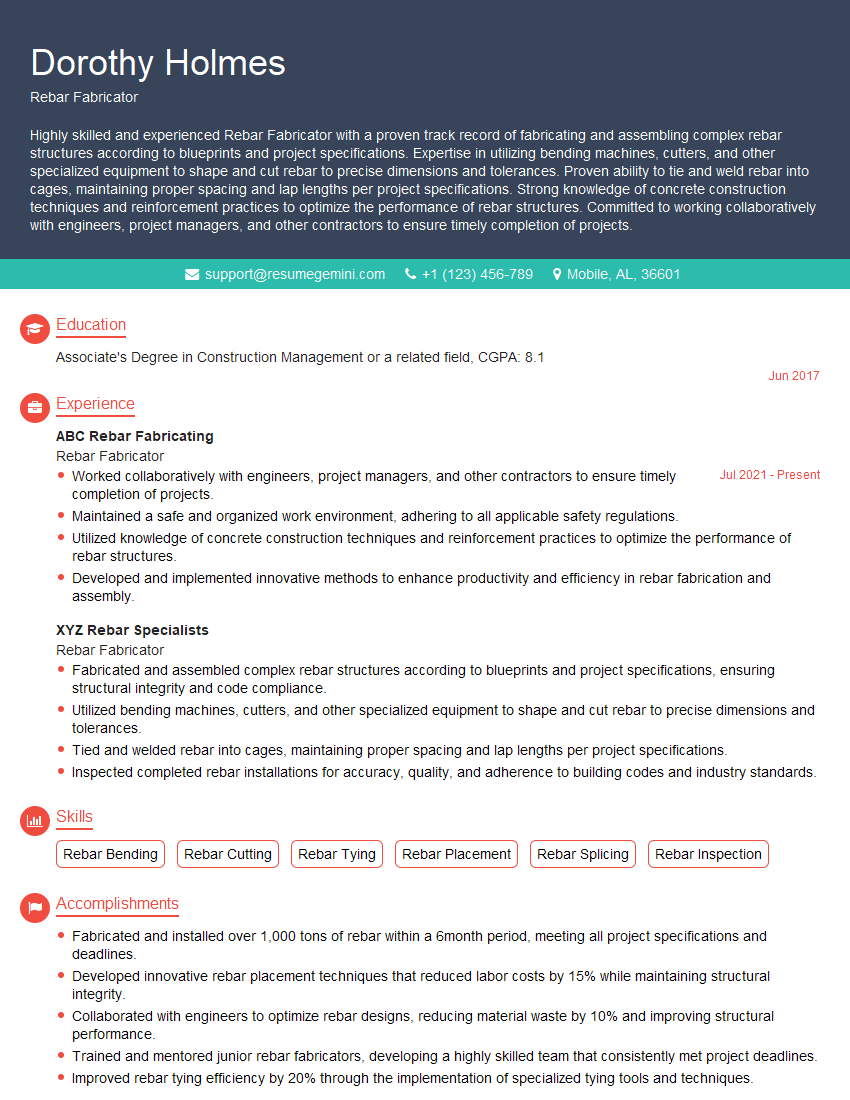

Dorothy Holmes

Rebar Fabricator

Summary

Highly skilled and experienced Rebar Fabricator with a proven track record of fabricating and assembling complex rebar structures according to blueprints and project specifications. Expertise in utilizing bending machines, cutters, and other specialized equipment to shape and cut rebar to precise dimensions and tolerances. Proven ability to tie and weld rebar into cages, maintaining proper spacing and lap lengths per project specifications. Strong knowledge of concrete construction techniques and reinforcement practices to optimize the performance of rebar structures. Committed to working collaboratively with engineers, project managers, and other contractors to ensure timely completion of projects.

Education

Associate’s Degree in Construction Management or a related field

June 2017

Skills

- Rebar Bending

- Rebar Cutting

- Rebar Tying

- Rebar Placement

- Rebar Splicing

- Rebar Inspection

Work Experience

Rebar Fabricator

- Worked collaboratively with engineers, project managers, and other contractors to ensure timely completion of projects.

- Maintained a safe and organized work environment, adhering to all applicable safety regulations.

- Utilized knowledge of concrete construction techniques and reinforcement practices to optimize the performance of rebar structures.

- Developed and implemented innovative methods to enhance productivity and efficiency in rebar fabrication and assembly.

Rebar Fabricator

- Fabricated and assembled complex rebar structures according to blueprints and project specifications, ensuring structural integrity and code compliance.

- Utilized bending machines, cutters, and other specialized equipment to shape and cut rebar to precise dimensions and tolerances.

- Tied and welded rebar into cages, maintaining proper spacing and lap lengths per project specifications.

- Inspected completed rebar installations for accuracy, quality, and adherence to building codes and industry standards.

Accomplishments

- Fabricated and installed over 1,000 tons of rebar within a 6month period, meeting all project specifications and deadlines.

- Developed innovative rebar placement techniques that reduced labor costs by 15% while maintaining structural integrity.

- Collaborated with engineers to optimize rebar designs, reducing material waste by 10% and improving structural performance.

- Trained and mentored junior rebar fabricators, developing a highly skilled team that consistently met project deadlines.

- Improved rebar tying efficiency by 20% through the implementation of specialized tying tools and techniques.

Awards

- Received Rebar Fabricator of the Year award for outstanding performance in rebar fabrication techniques and safety compliance.

- Recognized for exceptional attention to detail and accuracy in rebar bending and placement, resulting in zero structural defects.

- Awarded for consistently exceeding safety standards, maintaining a spotless safety record with zero accidents or injuries.

- Recognized for exceptional problemsolving skills, resolving complex rebar placement challenges and ensuring project completion.

Certificates

- ACI Concrete Field Testing Technician – Grade I

- OSHA 30-Hour Construction Safety Training

- National Institute for Certification in Engineering Technologies (NICET) Level I Rebar Detailing

- American Welding Society (AWS) D1.4 Welder Qualification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Rebar Fabricator

- Highlight your experience in fabricating and assembling complex rebar structures.

- Showcase your skills in utilizing bending machines, cutters, and other specialized equipment.

- Emphasize your ability to tie and weld rebar into cages, maintaining proper spacing and lap lengths.

- Demonstrate your knowledge of concrete construction techniques and reinforcement practices.

- Provide examples of your involvement in collaborative projects with engineers, project managers, and other contractors.

Essential Experience Highlights for a Strong Rebar Fabricator Resume

- Fabricate and assemble complex rebar structures according to blueprints and project specifications.

- Utilize bending machines, cutters, and other specialized equipment to shape and cut rebar to precise dimensions and tolerances.

- Tie and weld rebar into cages, maintaining proper spacing and lap lengths per project specifications.

- Inspect completed rebar installations for accuracy, quality, and adherence to building codes and industry standards.

- Work collaboratively with engineers, project managers, and other contractors to ensure timely completion of projects.

- Maintain a safe and organized work environment, adhering to all applicable safety regulations.

- Utilize knowledge of concrete construction techniques and reinforcement practices to optimize the performance of rebar structures.

Frequently Asked Questions (FAQ’s) For Rebar Fabricator

What are the key responsibilities of a Rebar Fabricator?

The key responsibilities of a Rebar Fabricator include fabricating and assembling rebar structures according to blueprints, utilizing specialized equipment to shape and cut rebar, tying and welding rebar into cages, inspecting completed installations, working collaboratively with project teams, maintaining a safe work environment, and utilizing knowledge of concrete construction techniques.

What skills are required to be a successful Rebar Fabricator?

To be a successful Rebar Fabricator, individuals should possess skills in rebar bending, cutting, tying, placement, splicing, and inspection. They should also have a strong understanding of concrete construction techniques and reinforcement practices.

What is the work environment of a Rebar Fabricator like?

Rebar Fabricators typically work in outdoor environments, often at construction sites. They may be exposed to various weather conditions and may need to work at heights.

What are the career advancement opportunities for Rebar Fabricators?

Rebar Fabricators with experience and additional training may advance to positions such as Foreman, Supervisor, or Project Manager. They may also choose to specialize in areas such as structural or architectural fabrication.

What are the safety precautions that Rebar Fabricators must follow?

Rebar Fabricators must follow safety precautions such as wearing appropriate protective gear, using equipment properly, and maintaining a clean and organized work area. They must also be aware of potential hazards such as sharp edges, heavy loads, and electrical equipment.