Are you a seasoned Reeling Operator seeking a new career path? Discover our professionally built Reeling Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

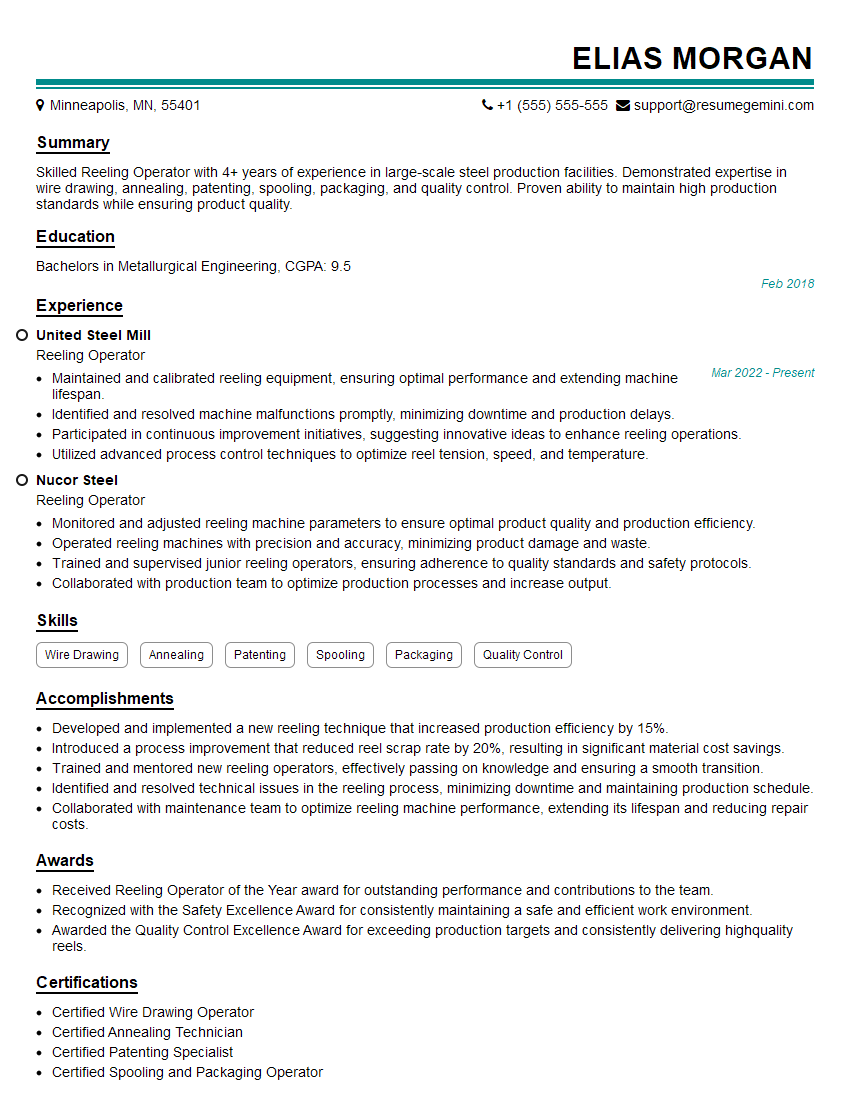

Elias Morgan

Reeling Operator

Summary

Skilled Reeling Operator with 4+ years of experience in large-scale steel production facilities. Demonstrated expertise in wire drawing, annealing, patenting, spooling, packaging, and quality control. Proven ability to maintain high production standards while ensuring product quality.

Education

Bachelors in Metallurgical Engineering

February 2018

Skills

- Wire Drawing

- Annealing

- Patenting

- Spooling

- Packaging

- Quality Control

Work Experience

Reeling Operator

- Maintained and calibrated reeling equipment, ensuring optimal performance and extending machine lifespan.

- Identified and resolved machine malfunctions promptly, minimizing downtime and production delays.

- Participated in continuous improvement initiatives, suggesting innovative ideas to enhance reeling operations.

- Utilized advanced process control techniques to optimize reel tension, speed, and temperature.

Reeling Operator

- Monitored and adjusted reeling machine parameters to ensure optimal product quality and production efficiency.

- Operated reeling machines with precision and accuracy, minimizing product damage and waste.

- Trained and supervised junior reeling operators, ensuring adherence to quality standards and safety protocols.

- Collaborated with production team to optimize production processes and increase output.

Accomplishments

- Developed and implemented a new reeling technique that increased production efficiency by 15%.

- Introduced a process improvement that reduced reel scrap rate by 20%, resulting in significant material cost savings.

- Trained and mentored new reeling operators, effectively passing on knowledge and ensuring a smooth transition.

- Identified and resolved technical issues in the reeling process, minimizing downtime and maintaining production schedule.

- Collaborated with maintenance team to optimize reeling machine performance, extending its lifespan and reducing repair costs.

Awards

- Received Reeling Operator of the Year award for outstanding performance and contributions to the team.

- Recognized with the Safety Excellence Award for consistently maintaining a safe and efficient work environment.

- Awarded the Quality Control Excellence Award for exceeding production targets and consistently delivering highquality reels.

Certificates

- Certified Wire Drawing Operator

- Certified Annealing Technician

- Certified Patenting Specialist

- Certified Spooling and Packaging Operator

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Reeling Operator

- Highlight your experience and expertise with different types of reeling machines, and various processes involved in wire production.

- Showcase your knowledge of quality control procedures and your ability to analyze and resolve production issues.

- Emphasize your familiarity with safety regulations and your commitment to maintaining a safe work environment.

- Consider obtaining industry certifications, such as the American Iron and Steel Institute’s (AISI) Reeling Operator certification, to enhance your professional credibility.

Essential Experience Highlights for a Strong Reeling Operator Resume

- Operate and monitor reeling machines to produce steel wire of various grades and dimensions.

- Control annealing and patenting processes to achieve the desired wire properties.

- Conduct quality control tests to verify compliance with specifications.

- Maintain and adjust machinery to optimize production efficiency.

- Monitor production processes and identify areas for improvement.

- Ensure a safe work environment and adhere to all safety regulations.

- Work effectively as part of a team to achieve production targets.

Frequently Asked Questions (FAQ’s) For Reeling Operator

What does a Reeling Operator do?

A Reeling Operator is responsible for the operation of wire drawing and reeling machines in the production of steel wire. They monitor and control the entire reeling process, including annealing, patenting, spooling, packaging, and quality control. Reeling Operators are also responsible for the maintenance and adjustment of machinery and the safe operation of their work environment.

What qualifications are required to become a Reeling Operator?

Most Reeling Operators hold a high school diploma or equivalent qualification. However, some employers may prefer candidates with a Bachelors in Metallurgical Engineering or related fields. Relevant work experience in a production or manufacturing environment is also highly beneficial.

What skills are needed to be a successful Reeling Operator?

Reeling Operators should possess strong mechanical aptitude and the ability to operate and maintain machinery. They should also have a good understanding of wire drawing and patenting processes, as well as quality control procedures. Excellent communication, problem-solving, and teamwork skills are also essential for success in this role.

What career opportunities are available to Reeling Operators?

Reeling Operators can progress into various roles within the wire production industry, such as Machine Supervisor or Production Manager. They can also specialize in areas such as quality control or maintenance. With additional education and experience, it is possible to move into roles in engineering or management.

What is the work environment of a Reeling Operator like?

Reeling Operators typically work in industrial manufacturing facilities, often around heavy machinery and potential hazards. They may be exposed to noise, heat, and chemicals, so wearing appropriate protective gear is essential. Reeling Operators may work varying shifts, including nights and weekends, to meet production demands.

What are the safety precautions that Reeling Operators should take?

Reeling Operators should always follow proper safety protocols when working with machinery. They should wear appropriate protective gear, including gloves, safety glasses, and hearing protection. Operators should be aware of potential hazards, such as moving parts, hot surfaces, and electrical components. They should also be properly trained on the operation of the machinery and emergency procedures.