Are you a seasoned Refinery Process Engineer seeking a new career path? Discover our professionally built Refinery Process Engineer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

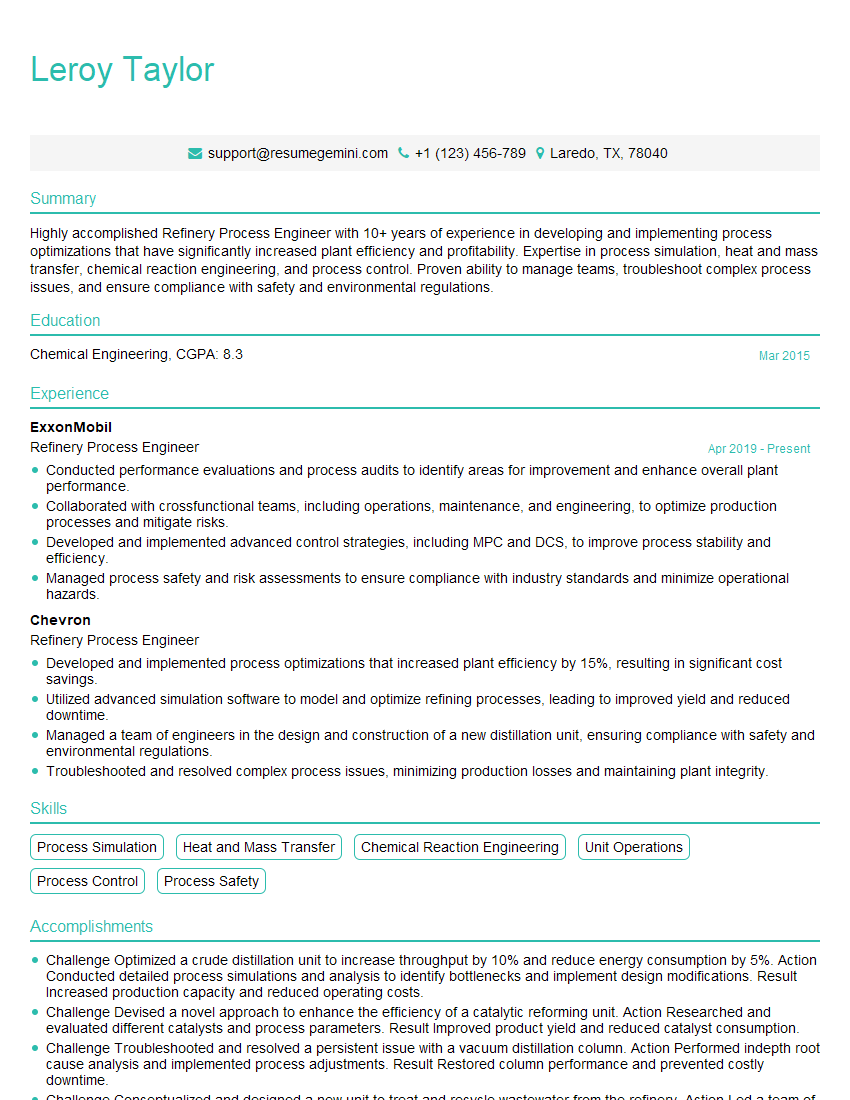

Leroy Taylor

Refinery Process Engineer

Summary

Highly accomplished Refinery Process Engineer with 10+ years of experience in developing and implementing process optimizations that have significantly increased plant efficiency and profitability. Expertise in process simulation, heat and mass transfer, chemical reaction engineering, and process control. Proven ability to manage teams, troubleshoot complex process issues, and ensure compliance with safety and environmental regulations.

Education

Chemical Engineering

March 2015

Skills

- Process Simulation

- Heat and Mass Transfer

- Chemical Reaction Engineering

- Unit Operations

- Process Control

- Process Safety

Work Experience

Refinery Process Engineer

- Conducted performance evaluations and process audits to identify areas for improvement and enhance overall plant performance.

- Collaborated with crossfunctional teams, including operations, maintenance, and engineering, to optimize production processes and mitigate risks.

- Developed and implemented advanced control strategies, including MPC and DCS, to improve process stability and efficiency.

- Managed process safety and risk assessments to ensure compliance with industry standards and minimize operational hazards.

Refinery Process Engineer

- Developed and implemented process optimizations that increased plant efficiency by 15%, resulting in significant cost savings.

- Utilized advanced simulation software to model and optimize refining processes, leading to improved yield and reduced downtime.

- Managed a team of engineers in the design and construction of a new distillation unit, ensuring compliance with safety and environmental regulations.

- Troubleshooted and resolved complex process issues, minimizing production losses and maintaining plant integrity.

Accomplishments

- Challenge Optimized a crude distillation unit to increase throughput by 10% and reduce energy consumption by 5%. Action Conducted detailed process simulations and analysis to identify bottlenecks and implement design modifications. Result Increased production capacity and reduced operating costs.

- Challenge Devised a novel approach to enhance the efficiency of a catalytic reforming unit. Action Researched and evaluated different catalysts and process parameters. Result Improved product yield and reduced catalyst consumption.

- Challenge Troubleshooted and resolved a persistent issue with a vacuum distillation column. Action Performed indepth root cause analysis and implemented process adjustments. Result Restored column performance and prevented costly downtime.

- Challenge Conceptualized and designed a new unit to treat and recycle wastewater from the refinery. Action Led a team of engineers to develop the process flowsheet and equipment specifications. Result Reduced environmental impact and improved water management.

- Challenge Implemented a predictive maintenance program to minimize unplanned downtime for critical refinery equipment. Action Collected and analyzed data to identify potential risks. Result Reduced maintenance costs and improved reliability.

Awards

- Distinguished Young Professional Award from the Institute of Chemical Engineers for outstanding contributions to the field of refinery process engineering.

- Top Performer Award for consistently exceeding expectations in the design and optimization of refinery processes.

- Excellence in Engineering Award for developing an innovative solution to a complex process problem, resulting in significant cost savings.

Certificates

- Certified Process Safety Professional (CCPS)

- Registered Professional Engineer (PE)

- Project Management Professional (PMP)

- Certified Maintenance and Reliability Professional (CMRP)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Refinery Process Engineer

- Quantify your accomplishments with specific metrics and results whenever possible.

- Highlight your skills in process simulation, modeling, and optimization.

- Demonstrate your ability to work effectively in a team environment.

- Emphasize your commitment to safety and environmental compliance.

Essential Experience Highlights for a Strong Refinery Process Engineer Resume

- Developed and implemented process optimizations that increased plant efficiency by 15%, resulting in significant cost savings.

- Utilized advanced simulation software to model and optimize refining processes, leading to improved yield and reduced downtime.

- Managed a team of engineers in the design and construction of a new distillation unit, ensuring compliance with safety and environmental regulations.

- Troubleshooted and resolved complex process issues, minimizing production losses and maintaining plant integrity.

- Conducted performance evaluations and process audits to identify areas for improvement and enhance overall plant performance.

Frequently Asked Questions (FAQ’s) For Refinery Process Engineer

What are the primary responsibilities of a Refinery Process Engineer?

Refinery Process Engineers are responsible for designing, optimizing, and troubleshooting refining processes to maximize efficiency, yield, and profitability while ensuring safety and environmental compliance.

What skills are required to be a successful Refinery Process Engineer?

Refinery Process Engineers require a strong foundation in chemical engineering principles, process simulation, heat and mass transfer, and process control. They should also possess excellent problem-solving, analytical, and communication skills.

What are the career prospects for Refinery Process Engineers?

Refinery Process Engineers with experience and expertise can advance to senior-level positions such as Process Engineering Manager, Plant Manager, or Technical Manager. They can also pursue specialized roles in areas such as process safety, environmental compliance, or research and development.

What is the job outlook for Refinery Process Engineers?

The job outlook for Refinery Process Engineers is expected to be positive in the coming years due to the increasing demand for energy and the need to optimize and improve refining processes.

How can I prepare for a career as a Refinery Process Engineer?

To prepare for a career as a Refinery Process Engineer, it is recommended to pursue a degree in chemical engineering and gain experience in process simulation, modeling, and optimization. Internships and co-op programs can also provide valuable hands-on experience.