Are you a seasoned Reflow Operator seeking a new career path? Discover our professionally built Reflow Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

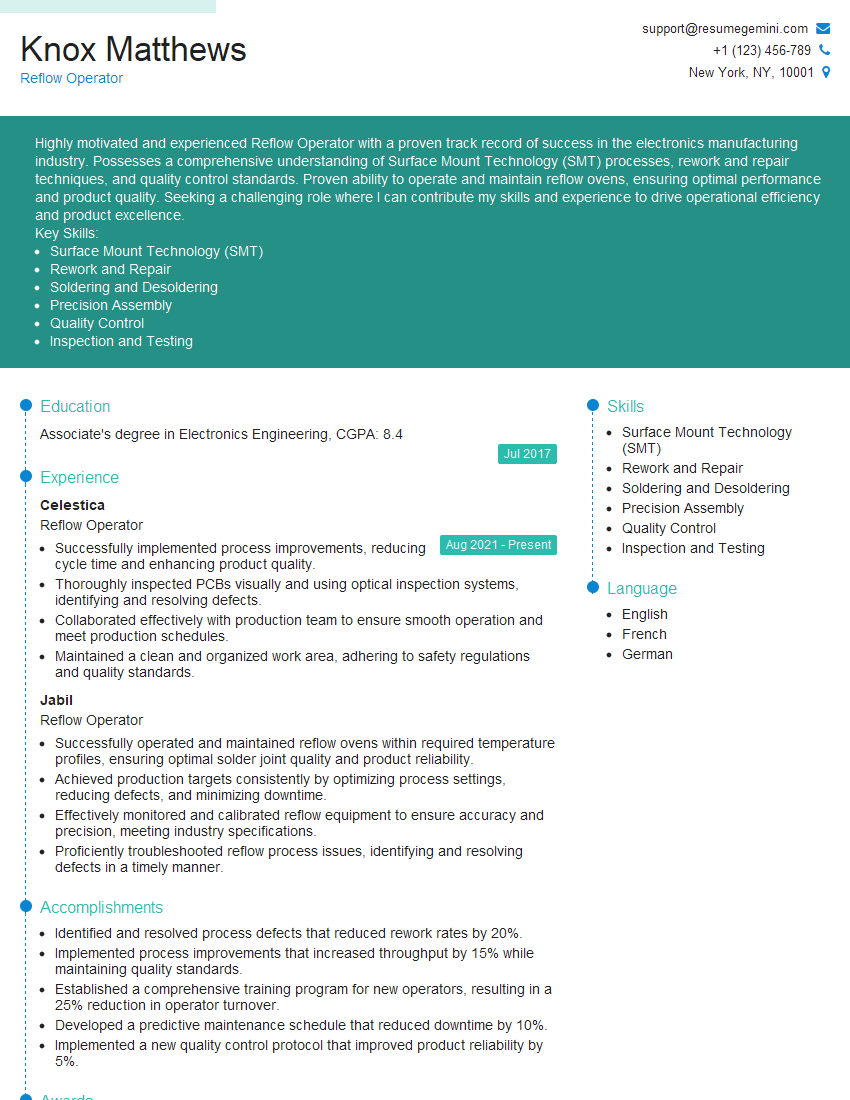

Knox Matthews

Reflow Operator

Summary

Highly motivated and experienced Reflow Operator with a proven track record of success in the electronics manufacturing industry. Possesses a comprehensive understanding of Surface Mount Technology (SMT) processes, rework and repair techniques, and quality control standards. Proven ability to operate and maintain reflow ovens, ensuring optimal performance and product quality. Seeking a challenging role where I can contribute my skills and experience to drive operational efficiency and product excellence.

Key Skills:

- Surface Mount Technology (SMT)

- Rework and Repair

- Soldering and Desoldering

- Precision Assembly

- Quality Control

- Inspection and Testing

Education

Associate’s degree in Electronics Engineering

July 2017

Skills

- Surface Mount Technology (SMT)

- Rework and Repair

- Soldering and Desoldering

- Precision Assembly

- Quality Control

- Inspection and Testing

Work Experience

Reflow Operator

- Successfully implemented process improvements, reducing cycle time and enhancing product quality.

- Thoroughly inspected PCBs visually and using optical inspection systems, identifying and resolving defects.

- Collaborated effectively with production team to ensure smooth operation and meet production schedules.

- Maintained a clean and organized work area, adhering to safety regulations and quality standards.

Reflow Operator

- Successfully operated and maintained reflow ovens within required temperature profiles, ensuring optimal solder joint quality and product reliability.

- Achieved production targets consistently by optimizing process settings, reducing defects, and minimizing downtime.

- Effectively monitored and calibrated reflow equipment to ensure accuracy and precision, meeting industry specifications.

- Proficiently troubleshooted reflow process issues, identifying and resolving defects in a timely manner.

Accomplishments

- Identified and resolved process defects that reduced rework rates by 20%.

- Implemented process improvements that increased throughput by 15% while maintaining quality standards.

- Established a comprehensive training program for new operators, resulting in a 25% reduction in operator turnover.

- Developed a predictive maintenance schedule that reduced downtime by 10%.

- Implemented a new quality control protocol that improved product reliability by 5%.

Awards

- Received the Outstanding Reflow Operator Award for maintaining exceptional cycle times and achieving 99.9% yield.

- Recognized for exceptional troubleshooting skills and quick resolution of production issues.

- Nominated for the Top Performer Award for consistently surpassing performance targets.

- Awarded the Safety Excellence Award for maintaining a spotless safety record.

Certificates

- IPC-A-610 Acceptability of Electronic Assemblies

- IPC/WHMA-A-620 Requirements and Acceptance for Cable and Wire Harness Assemblies

- Certified Reflow Operator (CRO)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Reflow Operator

- Highlight your technical skills and expertise in Surface Mount Technology (SMT) and reflow soldering.

- Quantify your accomplishments and provide specific examples of how you have contributed to quality and efficiency.

- Demonstrate your understanding of quality control standards and your commitment to producing high-quality products.

- Showcase your ability to work effectively in a team environment and your willingness to learn and adapt to new technologies.

Essential Experience Highlights for a Strong Reflow Operator Resume

- Operate and maintain reflow ovens, ensuring optimal temperature profiles and process parameters.

- Load and unload printed circuit boards (PCBs) into reflow ovens using automated or manual equipment.

- Monitor and adjust process parameters to meet specifications, including temperature, time, and cooling rates.

- Inspect PCBs for defects after reflow, identifying and documenting any non-conformances.

- Perform rework and repair of defective PCBs, using appropriate tools and techniques.

- Adhere to quality control standards and procedures, ensuring the production of high-quality products.

- Maintain a clean and organized work area, following established safety protocols.

Frequently Asked Questions (FAQ’s) For Reflow Operator

What is the primary role of a Reflow Operator?

The primary role of a Reflow Operator is to operate and maintain reflow ovens, ensuring optimal performance and product quality during the surface mount technology (SMT) process.

What are the key skills required for a Reflow Operator?

Key skills for a Reflow Operator include Surface Mount Technology (SMT) knowledge, rework and repair techniques, soldering and desoldering proficiency, precision assembly skills, quality control principles, and inspection and testing procedures.

What is the educational background typically required for a Reflow Operator?

While formal education requirements may vary, many Reflow Operators possess an Associate’s degree in Electronics Engineering or a related field.

What are the career advancement opportunities for a Reflow Operator?

Reflow Operators with experience and expertise can advance to roles such as Production Supervisor, Quality Control Inspector, or Process Engineer within the electronics manufacturing industry.

What are the safety protocols that Reflow Operators must follow?

Reflow Operators must adhere to established safety protocols, including proper handling and storage of chemicals, wearing appropriate personal protective equipment (PPE), and following lockout/tagout procedures when working on equipment.

What are the key quality control standards that Reflow Operators must follow?

Reflow Operators must follow quality control standards such as IPC-A-610 and IPC-6012, ensuring that PCBs meet specifications and industry best practices.

What are the latest trends and technologies in reflow soldering?

Recent advancements in reflow soldering include the use of lead-free solders, selective soldering, and vapor-phase reflow techniques, which aim to improve product quality, efficiency, and environmental sustainability.

How can Reflow Operators stay updated with the latest industry trends?

Reflow Operators can stay updated by attending industry conferences, reading technical journals, and participating in online forums and training programs.