Are you a seasoned Refractory Furnace Designer seeking a new career path? Discover our professionally built Refractory Furnace Designer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

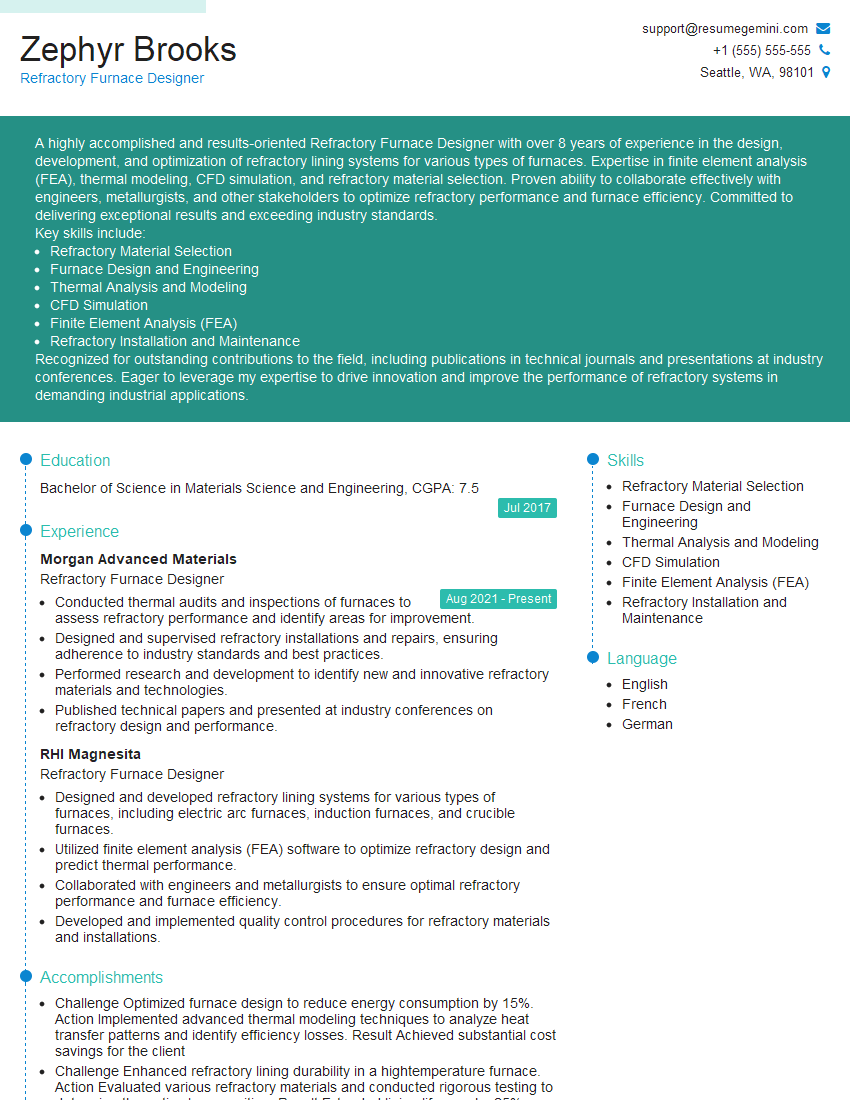

Zephyr Brooks

Refractory Furnace Designer

Summary

A highly accomplished and results-oriented Refractory Furnace Designer with over 8 years of experience in the design, development, and optimization of refractory lining systems for various types of furnaces. Expertise in finite element analysis (FEA), thermal modeling, CFD simulation, and refractory material selection. Proven ability to collaborate effectively with engineers, metallurgists, and other stakeholders to optimize refractory performance and furnace efficiency. Committed to delivering exceptional results and exceeding industry standards.

Key skills include:

- Refractory Material Selection

- Furnace Design and Engineering

- Thermal Analysis and Modeling

- CFD Simulation

- Finite Element Analysis (FEA)

- Refractory Installation and Maintenance

Recognized for outstanding contributions to the field, including publications in technical journals and presentations at industry conferences. Eager to leverage my expertise to drive innovation and improve the performance of refractory systems in demanding industrial applications.

Education

Bachelor of Science in Materials Science and Engineering

July 2017

Skills

- Refractory Material Selection

- Furnace Design and Engineering

- Thermal Analysis and Modeling

- CFD Simulation

- Finite Element Analysis (FEA)

- Refractory Installation and Maintenance

Work Experience

Refractory Furnace Designer

- Conducted thermal audits and inspections of furnaces to assess refractory performance and identify areas for improvement.

- Designed and supervised refractory installations and repairs, ensuring adherence to industry standards and best practices.

- Performed research and development to identify new and innovative refractory materials and technologies.

- Published technical papers and presented at industry conferences on refractory design and performance.

Refractory Furnace Designer

- Designed and developed refractory lining systems for various types of furnaces, including electric arc furnaces, induction furnaces, and crucible furnaces.

- Utilized finite element analysis (FEA) software to optimize refractory design and predict thermal performance.

- Collaborated with engineers and metallurgists to ensure optimal refractory performance and furnace efficiency.

- Developed and implemented quality control procedures for refractory materials and installations.

Accomplishments

- Challenge Optimized furnace design to reduce energy consumption by 15%. Action Implemented advanced thermal modeling techniques to analyze heat transfer patterns and identify efficiency losses. Result Achieved substantial cost savings for the client

- Challenge Enhanced refractory lining durability in a hightemperature furnace. Action Evaluated various refractory materials and conducted rigorous testing to determine the optimal composition. Result Extended lining lifespan by 25%, reducing maintenance downtime

- Challenge Developed a stateoftheart refractory design for a complex furnace assembly. Action Utilized advanced 3D CAD modeling and finite element analysis to ensure structural integrity and optimize performance. Result Ensured reliable operation and extended equipment longevity

- Challenge Streamlined refractory procurement and inventory management. Action Implemented an automated inventory system and established relationships with key suppliers. Result Reduced lead times and optimized material availability, improving project efficiency

- Challenge Enhanced safety measures for refractory installation and maintenance. Action Developed comprehensive safety protocols and trained personnel on proper handling techniques. Result Minimized risks and ensured compliance with industry standards

Awards

- Awarded Rising Star at the Refractory Furnace Design Conference for innovative contributions to the industry

- Recipient of the Technical Excellence Award from the American Society of Heating, Refrigeration and AirConditioning Engineers (ASHRAE) for developing a groundbreaking refractory design

Certificates

- Certified Refractory Engineer (CRE)

- American Ceramic Society (ACerS) Member

- National Board of Boiler and Pressure Vessel Inspectors (NBBI)

- OSHA 10-Hour Safety Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Refractory Furnace Designer

- Highlight your technical expertise: Emphasize your proficiency in refractory material selection, furnace design, and thermal analysis. Showcase your ability to apply engineering principles to optimize refractory systems and enhance furnace performance.

- Quantify your accomplishments: Use specific metrics and data to demonstrate the positive impact of your work. For example, quantify the improvements in furnace efficiency, refractory life, or energy consumption achieved through your design innovations.

- Showcase your problem-solving skills: Provide examples of how you have identified and resolved complex refractory issues. Highlight your ability to analyze furnace data, troubleshoot problems, and develop effective solutions.

- Demonstrate your commitment to continuous learning: Mention any industry certifications or professional development courses you have completed. Show that you are eager to stay abreast of the latest advancements in refractory technology and best practices.

- Tailor your resume to the specific job requirements: Carefully review the job description and identify the key skills and experience sought by the employer. Tailor your resume to highlight how your qualifications align with their needs.

Essential Experience Highlights for a Strong Refractory Furnace Designer Resume

- Design and develop refractory lining systems for various types of furnaces, including electric arc furnaces, induction furnaces, and crucible furnaces.

- Utilize finite element analysis (FEA) software to optimize refractory design and predict thermal performance.

- Collaborate with engineers and metallurgists to ensure optimal refractory performance and furnace efficiency.

- Develop and implement quality control procedures for refractory materials and installations.

- Conduct thermal audits and inspections of furnaces to assess refractory performance and identify areas for improvement.

- Design and supervise refractory installations and repairs, ensuring adherence to industry standards and best practices.

- Perform research and development to identify new and innovative refractory materials and technologies.

Frequently Asked Questions (FAQ’s) For Refractory Furnace Designer

What are the key responsibilities of a Refractory Furnace Designer?

The key responsibilities of a Refractory Furnace Designer include designing and developing refractory lining systems, optimizing refractory performance through thermal modeling and analysis, collaborating with engineers and metallurgists, implementing quality control procedures, conducting furnace inspections and audits, supervising refractory installations and repairs, and researching and developing new refractory materials and technologies.

What qualifications are required to become a Refractory Furnace Designer?

Typically, a Refractory Furnace Designer requires a Bachelor of Science in Materials Science and Engineering or a related field. Additionally, a strong understanding of refractory materials, furnace design, thermal analysis, and engineering principles is essential.

What are the career prospects for a Refractory Furnace Designer?

Refractory Furnace Designers are in high demand due to the increasing need for efficient and reliable refractory systems in various industries. With experience and expertise, Refractory Furnace Designers can advance to senior-level positions, such as Refractory Manager or Chief Refractory Engineer.

What are the key skills required for a successful Refractory Furnace Designer?

Key skills for a successful Refractory Furnace Designer include a strong understanding of refractory materials and their properties, proficiency in thermal modeling and analysis techniques, expertise in furnace design and engineering, excellent problem-solving and analytical abilities, and effective communication and collaboration skills.

What is the work environment for a Refractory Furnace Designer like?

Refractory Furnace Designers typically work in research and development laboratories, engineering offices, or industrial settings. They may be involved in both field and office work, including visiting customer sites, conducting furnace inspections, and collaborating with production teams.

What are the challenges faced by a Refractory Furnace Designer?

Refractory Furnace Designers face challenges related to optimizing refractory performance in demanding industrial environments. They must consider factors such as high temperatures, corrosive atmospheres, thermal stresses, and mechanical loads. Additionally, they need to stay updated on the latest advancements in refractory materials and technologies to meet evolving industry requirements.

What is the salary range for a Refractory Furnace Designer?

The salary range for a Refractory Furnace Designer varies depending on factors such as experience, qualifications, location, and industry. According to Salary.com, the average salary for a Refractory Furnace Designer in the United States is around $85,000 per year.

What are the professional organizations and resources available for Refractory Furnace Designers?

Refractory Furnace Designers can benefit from joining professional organizations such as the American Ceramic Society (ACerS), the Refractories Institute (RI), and the National Institute of Ceramic Engineers (NICE). These organizations provide opportunities for networking, professional development, and access to industry resources.