Are you a seasoned Refractory Manager seeking a new career path? Discover our professionally built Refractory Manager Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

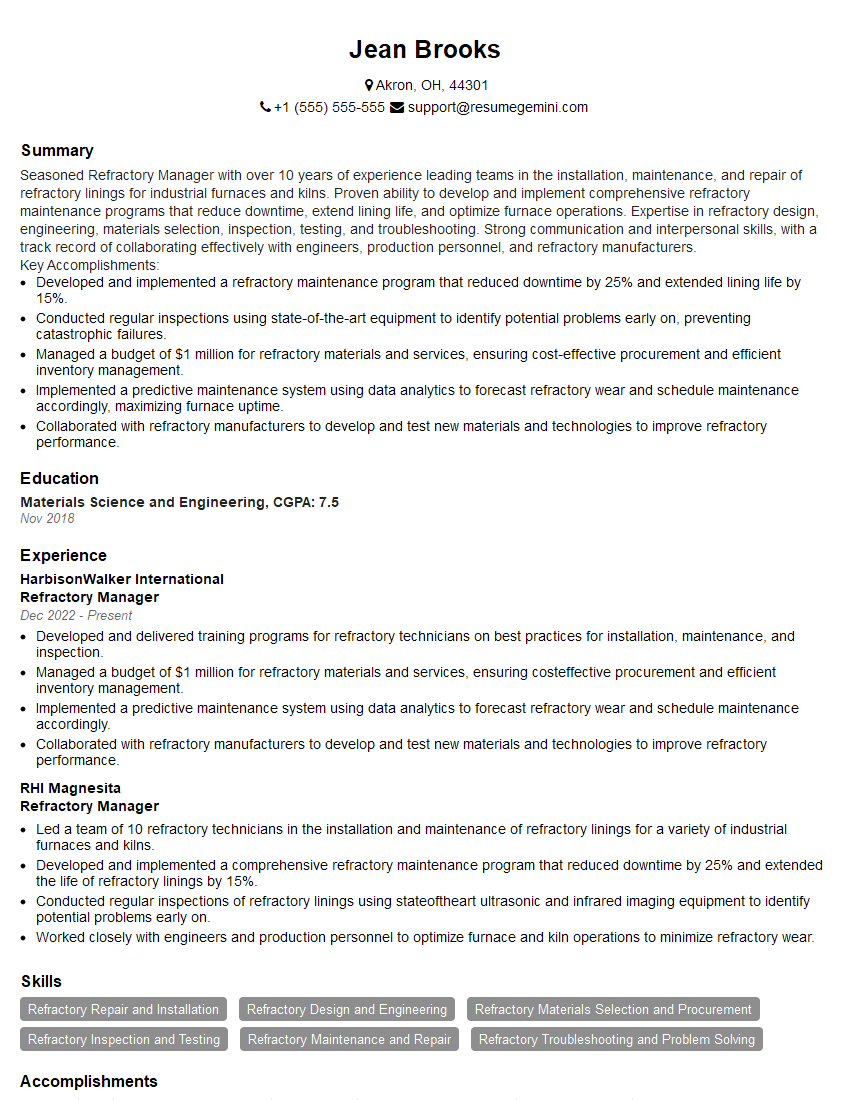

Jean Brooks

Refractory Manager

Summary

Seasoned Refractory Manager with over 10 years of experience leading teams in the installation, maintenance, and repair of refractory linings for industrial furnaces and kilns. Proven ability to develop and implement comprehensive refractory maintenance programs that reduce downtime, extend lining life, and optimize furnace operations. Expertise in refractory design, engineering, materials selection, inspection, testing, and troubleshooting. Strong communication and interpersonal skills, with a track record of collaborating effectively with engineers, production personnel, and refractory manufacturers.

Key Accomplishments:

- Developed and implemented a refractory maintenance program that reduced downtime by 25% and extended lining life by 15%.

- Conducted regular inspections using state-of-the-art equipment to identify potential problems early on, preventing catastrophic failures.

- Managed a budget of $1 million for refractory materials and services, ensuring cost-effective procurement and efficient inventory management.

- Implemented a predictive maintenance system using data analytics to forecast refractory wear and schedule maintenance accordingly, maximizing furnace uptime.

- Collaborated with refractory manufacturers to develop and test new materials and technologies to improve refractory performance.

Education

Materials Science and Engineering

November 2018

Skills

- Refractory Repair and Installation

- Refractory Design and Engineering

- Refractory Materials Selection and Procurement

- Refractory Inspection and Testing

- Refractory Maintenance and Repair

- Refractory Troubleshooting and Problem Solving

Work Experience

Refractory Manager

- Developed and delivered training programs for refractory technicians on best practices for installation, maintenance, and inspection.

- Managed a budget of $1 million for refractory materials and services, ensuring costeffective procurement and efficient inventory management.

- Implemented a predictive maintenance system using data analytics to forecast refractory wear and schedule maintenance accordingly.

- Collaborated with refractory manufacturers to develop and test new materials and technologies to improve refractory performance.

Refractory Manager

- Led a team of 10 refractory technicians in the installation and maintenance of refractory linings for a variety of industrial furnaces and kilns.

- Developed and implemented a comprehensive refractory maintenance program that reduced downtime by 25% and extended the life of refractory linings by 15%.

- Conducted regular inspections of refractory linings using stateoftheart ultrasonic and infrared imaging equipment to identify potential problems early on.

- Worked closely with engineers and production personnel to optimize furnace and kiln operations to minimize refractory wear.

Accomplishments

- Led a team to develop and implement a new refractory lining design for a critical furnace, resulting in a 35% increase in furnace lifespan and a significant reduction in refractory maintenance costs.

- Successfully managed the refractory inventory for a complex multifurnace plant, optimizing stock levels, reducing inventory costs, and ensuring uninterrupted operations.

- Developed and implemented a predictive maintenance system for refractory linings, reducing unplanned outages and improving overall plant availability.

- Collaborated with suppliers to negotiate favorable refractory prices and terms, resulting in significant cost savings for the organization.

- Successfully optimized refractory installation techniques, reducing installation time and improving the quality of refractory linings.

Awards

- Received the Refractory Manager of the Year award for outstanding performance in optimizing refractory usage, reducing maintenance downtime, and improving overall plant efficiency.

- Recognized for excellence in refractory management during a major plant expansion, ensuring smooth operations and timely project completion.

- Received a commendation for implementing a comprehensive refractory testing program, improving refractory performance and reliability.

- Recognized for exceptional leadership in managing a team of refractory technicians and engineers, fostering a culture of excellence and innovation.

Certificates

- American Ceramic Society (ACS) Certified Refractory Engineer

- American Institute of Plant Engineers (AIPE) Certified Maintenance Manager (CMM)

- American Society for Nondestructive Testing (ASNT) Level II Inspector

- National Board of Boiler and Pressure Vessel Inspectors (NBBI) Commission

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Refractory Manager

- Highlight your technical expertise in refractory materials, design, engineering, and maintenance.

- Quantify your accomplishments with specific metrics and results, demonstrating the impact of your work.

- Showcase your leadership and management skills, emphasizing your ability to motivate and guide teams.

- Demonstrate your commitment to continuous improvement and innovation by sharing examples of how you have developed and implemented new technologies or processes.

- Proofread your resume carefully for any errors or inconsistencies.

Essential Experience Highlights for a Strong Refractory Manager Resume

- Lead and manage a team of refractory technicians in the installation, maintenance, and repair of refractory linings.

- Develop and implement comprehensive refractory maintenance programs to minimize downtime and extend lining life.

- Conduct regular inspections of refractory linings using state-of-the-art ultrasonic and infrared imaging equipment.

- Work closely with engineers and production personnel to optimize furnace and kiln operations to minimize refractory wear.

- Develop and deliver training programs for refractory technicians on best practices for installation, maintenance, and inspection.

- Manage a budget for refractory materials and services, ensuring cost-effective procurement and efficient inventory management.

- Collaborate with refractory manufacturers to develop and test new materials and technologies to improve refractory performance.

Frequently Asked Questions (FAQ’s) For Refractory Manager

What is the role of a Refractory Manager?

A Refractory Manager is responsible for overseeing the installation, maintenance, and repair of refractory linings in industrial furnaces and kilns. They develop and implement maintenance programs, conduct inspections, and work closely with engineers and production personnel to optimize furnace operations and minimize refractory wear.

What qualifications are required to become a Refractory Manager?

Typically, a Refractory Manager holds a degree in Materials Science and Engineering or a related field, and has several years of experience in the refractory industry. They should have a strong understanding of refractory materials, design, engineering, and maintenance practices.

What are the key responsibilities of a Refractory Manager?

Key responsibilities of a Refractory Manager include leading and managing a team of refractory technicians, developing and implementing refractory maintenance programs, conducting regular inspections, working with engineers and production personnel to optimize furnace operations, managing a budget, and collaborating with refractory manufacturers.

What skills are important for a Refractory Manager?

Important skills for a Refractory Manager include technical expertise in refractory materials, design, engineering, and maintenance, as well as leadership, management, communication, and problem-solving skills.

What is the job outlook for Refractory Managers?

The job outlook for Refractory Managers is expected to be good over the next few years, as there is a growing demand for qualified professionals in the refractory industry.

What are the earning prospects for Refractory Managers?

Earning prospects for Refractory Managers vary depending on experience, qualifications, and location. However, they can earn a competitive salary and benefits package.

How can I become a Refractory Manager?

To become a Refractory Manager, you can earn a degree in Materials Science and Engineering or a related field, gain experience in the refractory industry, and develop the necessary skills and knowledge.