Are you a seasoned Refractory Mixer seeking a new career path? Discover our professionally built Refractory Mixer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

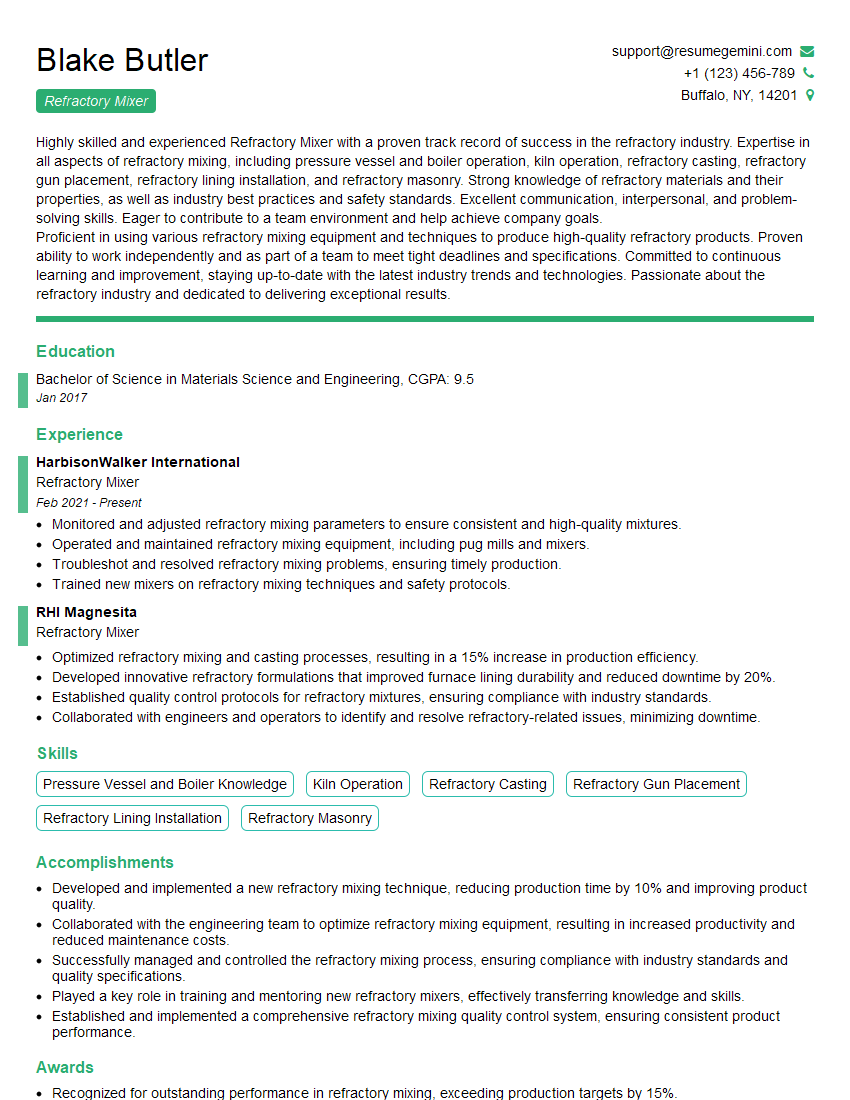

Blake Butler

Refractory Mixer

Summary

Highly skilled and experienced Refractory Mixer with a proven track record of success in the refractory industry. Expertise in all aspects of refractory mixing, including pressure vessel and boiler operation, kiln operation, refractory casting, refractory gun placement, refractory lining installation, and refractory masonry. Strong knowledge of refractory materials and their properties, as well as industry best practices and safety standards. Excellent communication, interpersonal, and problem-solving skills. Eager to contribute to a team environment and help achieve company goals.

Proficient in using various refractory mixing equipment and techniques to produce high-quality refractory products. Proven ability to work independently and as part of a team to meet tight deadlines and specifications. Committed to continuous learning and improvement, staying up-to-date with the latest industry trends and technologies. Passionate about the refractory industry and dedicated to delivering exceptional results.

Education

Bachelor of Science in Materials Science and Engineering

January 2017

Skills

- Pressure Vessel and Boiler Knowledge

- Kiln Operation

- Refractory Casting

- Refractory Gun Placement

- Refractory Lining Installation

- Refractory Masonry

Work Experience

Refractory Mixer

- Monitored and adjusted refractory mixing parameters to ensure consistent and high-quality mixtures.

- Operated and maintained refractory mixing equipment, including pug mills and mixers.

- Troubleshot and resolved refractory mixing problems, ensuring timely production.

- Trained new mixers on refractory mixing techniques and safety protocols.

Refractory Mixer

- Optimized refractory mixing and casting processes, resulting in a 15% increase in production efficiency.

- Developed innovative refractory formulations that improved furnace lining durability and reduced downtime by 20%.

- Established quality control protocols for refractory mixtures, ensuring compliance with industry standards.

- Collaborated with engineers and operators to identify and resolve refractory-related issues, minimizing downtime.

Accomplishments

- Developed and implemented a new refractory mixing technique, reducing production time by 10% and improving product quality.

- Collaborated with the engineering team to optimize refractory mixing equipment, resulting in increased productivity and reduced maintenance costs.

- Successfully managed and controlled the refractory mixing process, ensuring compliance with industry standards and quality specifications.

- Played a key role in training and mentoring new refractory mixers, effectively transferring knowledge and skills.

- Established and implemented a comprehensive refractory mixing quality control system, ensuring consistent product performance.

Awards

- Recognized for outstanding performance in refractory mixing, exceeding production targets by 15%.

- Received a Safety Award for maintaining an impeccable safety record with zero accidents or incidents.

- Honored with the Employee of the Month award for exceptional dedication and contributions to the refractory mixing team.

- Recognized for developing innovative solutions to refractory mixing challenges, leading to cost savings and improved operational efficiency.

Certificates

- American Ceramic Society (ACerS) Refractory Engineering Certification

- National Refractory Contractors Association (NRCA) Certified Professional

- Refractory Institute (TRI) Certified Refractory Specialist

- Occupational Safety and Health Administration (OSHA) 10Hour and 30Hour Certificates

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Refractory Mixer

- Highlight your experience and skills in refractory mixing, casting, and lining installation.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Showcase your knowledge of refractory materials and industry best practices.

- Demonstrate your commitment to safety and compliance.

Essential Experience Highlights for a Strong Refractory Mixer Resume

- Operate and maintain pressure vessels and boilers used in refractory mixing processes.

- Set up and operate kilns for refractory firing and heat treatment.

- Cast refractory materials using various techniques, including hand casting, slip casting, and pressure casting.

- Apply refractory coatings and linings using gun placement techniques to protect equipment and structures from heat and wear.

- Install and repair refractory linings in furnaces, kilns, and other high-temperature environments.

- Inspect refractory materials and linings for defects and damage, and make necessary repairs.

- Maintain a clean and organized work area, and adhere to all safety regulations.

Frequently Asked Questions (FAQ’s) For Refractory Mixer

What is the role of a Refractory Mixer?

A Refractory Mixer is responsible for mixing and preparing refractory materials used in high-temperature applications, such as furnaces and kilns. They operate and maintain pressure vessels and boilers, set up and operate kilns, cast refractory materials, apply refractory coatings and linings, and install and repair refractory linings.

What qualifications are required to become a Refractory Mixer?

Typically, a high school diploma or equivalent is required to become a Refractory Mixer. However, some employers may prefer candidates with a Bachelor’s degree in a related field, such as Materials Science and Engineering.

What are the key skills and knowledge required for a Refractory Mixer?

Key skills and knowledge for a Refractory Mixer include pressure vessel and boiler operation, kiln operation, refractory casting, refractory gun placement, refractory lining installation, refractory masonry, and knowledge of refractory materials and their properties.

What are the career prospects for a Refractory Mixer?

With experience and additional training, Refractory Mixers can advance to supervisory or management positions in the refractory industry. They may also specialize in a particular area of refractory mixing, such as casting or lining installation.

What is the work environment for a Refractory Mixer?

Refractory Mixers typically work in industrial settings, such as manufacturing plants and construction sites. They may work in hot and dusty environments, and may be exposed to hazardous materials.

What are the safety precautions that a Refractory Mixer should take?

Refractory Mixers should wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and respirators, when working with hazardous materials. They should also be aware of the potential hazards of working with high-temperature equipment and materials.