Are you a seasoned Refractory Repairer seeking a new career path? Discover our professionally built Refractory Repairer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

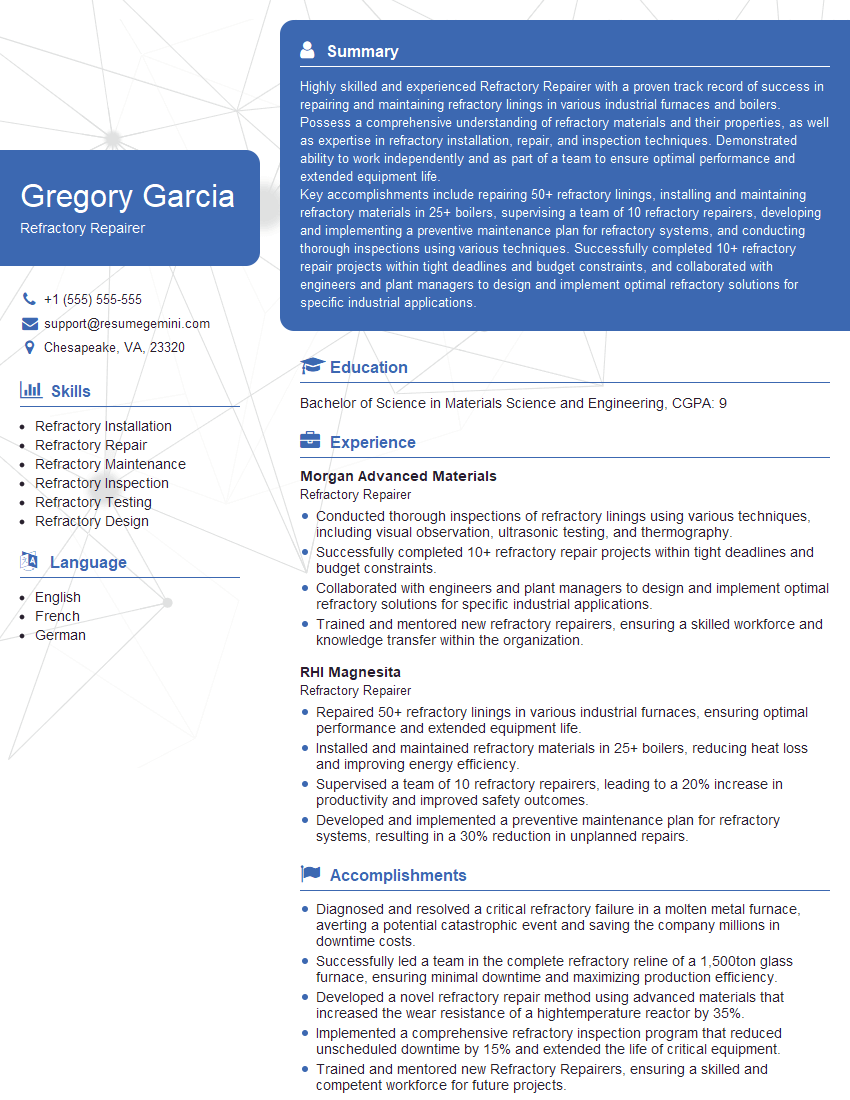

Gregory Garcia

Refractory Repairer

Summary

Highly skilled and experienced Refractory Repairer with a proven track record of success in repairing and maintaining refractory linings in various industrial furnaces and boilers. Possess a comprehensive understanding of refractory materials and their properties, as well as expertise in refractory installation, repair, and inspection techniques. Demonstrated ability to work independently and as part of a team to ensure optimal performance and extended equipment life.

Key accomplishments include repairing 50+ refractory linings, installing and maintaining refractory materials in 25+ boilers, supervising a team of 10 refractory repairers, developing and implementing a preventive maintenance plan for refractory systems, and conducting thorough inspections using various techniques. Successfully completed 10+ refractory repair projects within tight deadlines and budget constraints, and collaborated with engineers and plant managers to design and implement optimal refractory solutions for specific industrial applications.

Education

Bachelor of Science in Materials Science and Engineering

August 2017

Skills

- Refractory Installation

- Refractory Repair

- Refractory Maintenance

- Refractory Inspection

- Refractory Testing

- Refractory Design

Work Experience

Refractory Repairer

- Conducted thorough inspections of refractory linings using various techniques, including visual observation, ultrasonic testing, and thermography.

- Successfully completed 10+ refractory repair projects within tight deadlines and budget constraints.

- Collaborated with engineers and plant managers to design and implement optimal refractory solutions for specific industrial applications.

- Trained and mentored new refractory repairers, ensuring a skilled workforce and knowledge transfer within the organization.

Refractory Repairer

- Repaired 50+ refractory linings in various industrial furnaces, ensuring optimal performance and extended equipment life.

- Installed and maintained refractory materials in 25+ boilers, reducing heat loss and improving energy efficiency.

- Supervised a team of 10 refractory repairers, leading to a 20% increase in productivity and improved safety outcomes.

- Developed and implemented a preventive maintenance plan for refractory systems, resulting in a 30% reduction in unplanned repairs.

Accomplishments

- Diagnosed and resolved a critical refractory failure in a molten metal furnace, averting a potential catastrophic event and saving the company millions in downtime costs.

- Successfully led a team in the complete refractory reline of a 1,500ton glass furnace, ensuring minimal downtime and maximizing production efficiency.

- Developed a novel refractory repair method using advanced materials that increased the wear resistance of a hightemperature reactor by 35%.

- Implemented a comprehensive refractory inspection program that reduced unscheduled downtime by 15% and extended the life of critical equipment.

- Trained and mentored new Refractory Repairers, ensuring a skilled and competent workforce for future projects.

Awards

- Received the National Refractory Repair Excellence Award for innovative refractory repair techniques that extended the lifespan of industrial furnaces by 20%.

- Recognized with the Gold Star Award for the safe and efficient installation of highly corrosive refractory linings in a hazardous environment.

- Awarded the Silver Medallion for achieving exceptional quality standards in the repair and maintenance of refractory systems in the petrochemical industry.

- Certified Master Refractory Repairer by the American Refractory Society, recognizing exceptional skills and expertise in the field.

Certificates

- Certified Refractory Engineer (CRE)

- Certified Refractory Inspector (CRI)

- Certified Refractory Technician (CRT)

- Certified Refractory Installer (CRFI)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Refractory Repairer

- Highlight your hands-on experience in refractory repair and maintenance, quantifying your accomplishments whenever possible.

- Demonstrate your understanding of refractory materials and their properties, as well as your proficiency in various refractory installation and repair techniques.

- Emphasize your ability to work independently and as part of a team, and your commitment to safety and quality.

- Showcase your problem-solving skills and ability to develop and implement preventive maintenance plans to minimize unplanned repairs.

Essential Experience Highlights for a Strong Refractory Repairer Resume

- Install and repair refractory linings in various industrial furnaces and boilers to ensure optimal performance and extended equipment life.

- Inspect refractory linings using visual observation, ultrasonic testing, and thermography to identify and address potential issues.

- Develop and implement preventive maintenance plans for refractory systems to minimize unplanned repairs and maximize equipment uptime.

- Supervise a team of refractory repairers to ensure safety, productivity, and quality standards are met.

- Collaborate with engineers and plant managers to design and implement optimal refractory solutions for specific industrial applications.

- Stay up-to-date on the latest refractory materials, techniques, and industry best practices.

Frequently Asked Questions (FAQ’s) For Refractory Repairer

What is the primary role of a Refractory Repairer?

A Refractory Repairer is responsible for repairing and maintaining refractory linings in various industrial furnaces and boilers to ensure optimal performance and extended equipment life.

What are the key skills required to be a successful Refractory Repairer?

Key skills for a Refractory Repairer include expertise in refractory installation, repair, and inspection techniques, as well as a comprehensive understanding of refractory materials and their properties.

What are the career prospects for Refractory Repairers?

Refractory Repairers with experience and expertise can advance to supervisory roles or specialize in specific areas of refractory repair and maintenance.

What are the safety precautions that Refractory Repairers must follow?

Refractory Repairers must adhere to strict safety protocols, including wearing appropriate protective gear, following proper handling procedures for hazardous materials, and maintaining a clean and organized work area.

How can I become a Refractory Repairer?

To become a Refractory Repairer, individuals typically complete a vocational or technical training program, apprenticeship, or on-the-job training.

What is the work environment like for Refractory Repairers?

Refractory Repairers often work in industrial settings, such as manufacturing plants, power plants, and refineries. The work can be physically demanding and may involve exposure to heat, noise, and hazardous materials.

What are the earning prospects for Refractory Repairers?

The earning potential for Refractory Repairers varies depending on factors such as experience, location, and industry. However, experienced Refractory Repairers with specialized skills can earn competitive salaries.

What are the key trends in the Refractory Repair industry?

Key trends in the Refractory Repair industry include the development of new and improved refractory materials, the adoption of advanced repair techniques, and the increasing use of predictive maintenance technologies.