Are you a seasoned Refractory Technician seeking a new career path? Discover our professionally built Refractory Technician Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

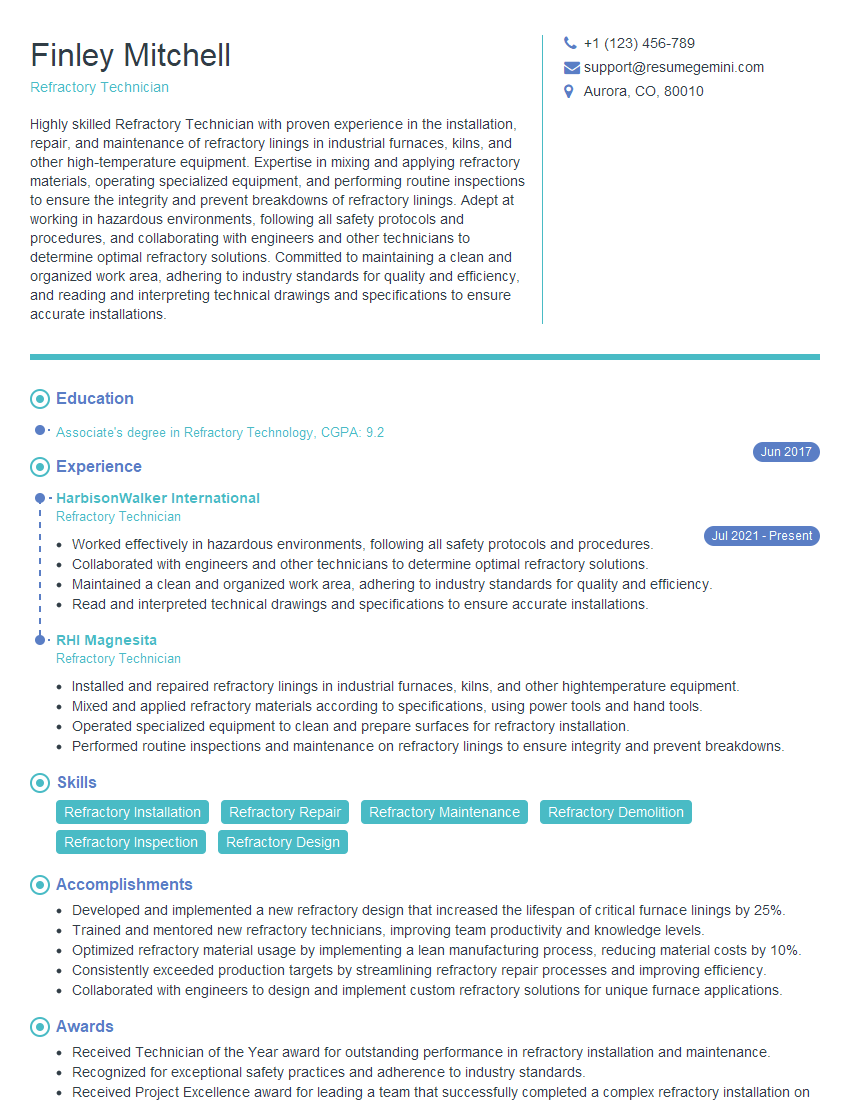

Finley Mitchell

Refractory Technician

Summary

Highly skilled Refractory Technician with proven experience in the installation, repair, and maintenance of refractory linings in industrial furnaces, kilns, and other high-temperature equipment. Expertise in mixing and applying refractory materials, operating specialized equipment, and performing routine inspections to ensure the integrity and prevent breakdowns of refractory linings. Adept at working in hazardous environments, following all safety protocols and procedures, and collaborating with engineers and other technicians to determine optimal refractory solutions. Committed to maintaining a clean and organized work area, adhering to industry standards for quality and efficiency, and reading and interpreting technical drawings and specifications to ensure accurate installations.

Education

Associate’s degree in Refractory Technology

June 2017

Skills

- Refractory Installation

- Refractory Repair

- Refractory Maintenance

- Refractory Demolition

- Refractory Inspection

- Refractory Design

Work Experience

Refractory Technician

- Worked effectively in hazardous environments, following all safety protocols and procedures.

- Collaborated with engineers and other technicians to determine optimal refractory solutions.

- Maintained a clean and organized work area, adhering to industry standards for quality and efficiency.

- Read and interpreted technical drawings and specifications to ensure accurate installations.

Refractory Technician

- Installed and repaired refractory linings in industrial furnaces, kilns, and other hightemperature equipment.

- Mixed and applied refractory materials according to specifications, using power tools and hand tools.

- Operated specialized equipment to clean and prepare surfaces for refractory installation.

- Performed routine inspections and maintenance on refractory linings to ensure integrity and prevent breakdowns.

Accomplishments

- Developed and implemented a new refractory design that increased the lifespan of critical furnace linings by 25%.

- Trained and mentored new refractory technicians, improving team productivity and knowledge levels.

- Optimized refractory material usage by implementing a lean manufacturing process, reducing material costs by 10%.

- Consistently exceeded production targets by streamlining refractory repair processes and improving efficiency.

- Collaborated with engineers to design and implement custom refractory solutions for unique furnace applications.

Awards

- Received Technician of the Year award for outstanding performance in refractory installation and maintenance.

- Recognized for exceptional safety practices and adherence to industry standards.

- Received Project Excellence award for leading a team that successfully completed a complex refractory installation on time and within budget.

- Certified as a Level 2 Refractory Technician by the National Refractory Technicians Association.

Certificates

- American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code Certification

- National Board of Boiler and Pressure Vessel Inspectors (NBBI) Certification

- Refractory Material Institute (RMI) Certification

- American Ceramic Society (ACerS) Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Refractory Technician

- Highlight your experience and skills in refractory installation, repair, and maintenance.

- Showcase your knowledge of refractory materials and their applications.

- Emphasize your ability to work in hazardous environments and follow safety protocols.

- Include any certifications or training related to refractory technology.

- Quantify your accomplishments whenever possible, using specific numbers and metrics.

Essential Experience Highlights for a Strong Refractory Technician Resume

- Installed and repaired refractory linings in industrial furnaces, kilns, and other high-temperature equipment.

- Mixed and applied refractory materials according to specifications, using power tools and hand tools.

- Operated specialized equipment to clean and prepare surfaces for refractory installation.

- Performed routine inspections and maintenance on refractory linings to ensure integrity and prevent breakdowns.

- Worked effectively in hazardous environments, following all safety protocols and procedures.

- Collaborated with engineers and other technicians to determine optimal refractory solutions.

- Maintained a clean and organized work area, adhering to industry standards for quality and efficiency.

- Read and interpreted technical drawings and specifications to ensure accurate installations.

Frequently Asked Questions (FAQ’s) For Refractory Technician

What is the role of a Refractory Technician?

A Refractory Technician is responsible for installing, repairing, and maintaining refractory linings in industrial furnaces, kilns, and other high-temperature equipment. They mix and apply refractory materials, operate specialized equipment, and perform routine inspections to ensure the integrity of the refractory linings.

What are the qualifications for a Refractory Technician?

Most Refractory Technicians have an associate’s degree in Refractory Technology or a related field. They also have experience in the installation, repair, and maintenance of refractory linings. Additionally, they must be able to work in hazardous environments and follow safety protocols.

What are the key skills for a Refractory Technician?

Key skills for a Refractory Technician include the ability to install and repair refractory linings, mix and apply refractory materials, operate specialized equipment, and perform routine inspections. They must also be able to work in hazardous environments and follow safety protocols.

What are the career prospects for a Refractory Technician?

Refractory Technicians can advance to positions such as Refractory Supervisor or Refractory Engineer. They can also start their own businesses.

What is the salary range for a Refractory Technician?

The salary range for a Refractory Technician varies depending on experience, location, and company size. According to Indeed, the average salary for a Refractory Technician in the United States is $62,000 per year.

What are the working conditions for a Refractory Technician?

Refractory Technicians typically work in industrial settings, such as factories and power plants. They may be exposed to heat, dust, and fumes. They must also be able to work in confined spaces.