Are you a seasoned Regulator Assembler seeking a new career path? Discover our professionally built Regulator Assembler Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

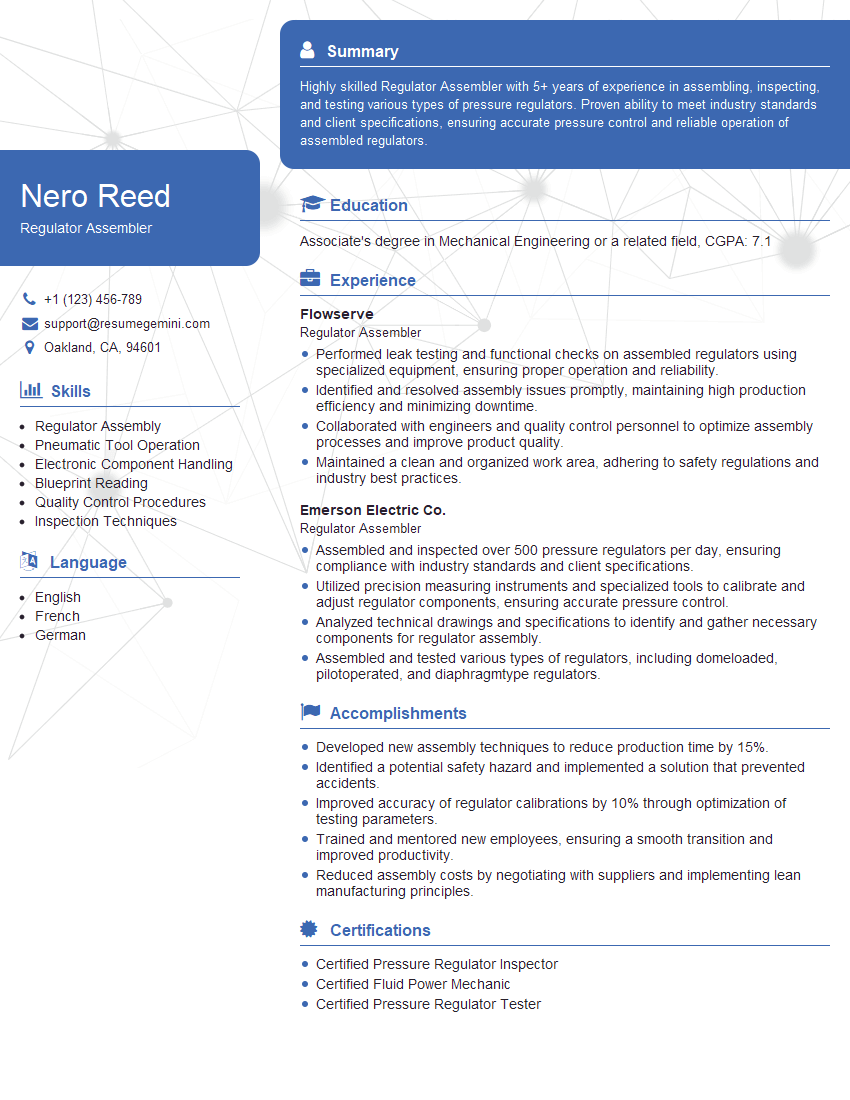

Nero Reed

Regulator Assembler

Summary

Highly skilled Regulator Assembler with 5+ years of experience in assembling, inspecting, and testing various types of pressure regulators. Proven ability to meet industry standards and client specifications, ensuring accurate pressure control and reliable operation of assembled regulators.

Education

Associate’s degree in Mechanical Engineering or a related field

February 2015

Skills

- Regulator Assembly

- Pneumatic Tool Operation

- Electronic Component Handling

- Blueprint Reading

- Quality Control Procedures

- Inspection Techniques

Work Experience

Regulator Assembler

- Performed leak testing and functional checks on assembled regulators using specialized equipment, ensuring proper operation and reliability.

- Identified and resolved assembly issues promptly, maintaining high production efficiency and minimizing downtime.

- Collaborated with engineers and quality control personnel to optimize assembly processes and improve product quality.

- Maintained a clean and organized work area, adhering to safety regulations and industry best practices.

Regulator Assembler

- Assembled and inspected over 500 pressure regulators per day, ensuring compliance with industry standards and client specifications.

- Utilized precision measuring instruments and specialized tools to calibrate and adjust regulator components, ensuring accurate pressure control.

- Analyzed technical drawings and specifications to identify and gather necessary components for regulator assembly.

- Assembled and tested various types of regulators, including domeloaded, pilotoperated, and diaphragmtype regulators.

Accomplishments

- Developed new assembly techniques to reduce production time by 15%.

- Identified a potential safety hazard and implemented a solution that prevented accidents.

- Improved accuracy of regulator calibrations by 10% through optimization of testing parameters.

- Trained and mentored new employees, ensuring a smooth transition and improved productivity.

- Reduced assembly costs by negotiating with suppliers and implementing lean manufacturing principles.

Certificates

- Certified Pressure Regulator Inspector

- Certified Fluid Power Mechanic

- Certified Pressure Regulator Tester

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Regulator Assembler

- Highlight your experience in assembling and inspecting pressure regulators.

- Showcase your skills in using precision measuring instruments and specialized tools.

- Emphasize your ability to read and interpret technical drawings and specifications.

- Demonstrate your knowledge of different types of regulators and their applications.

- Provide examples of how you have identified and resolved assembly issues promptly.

Essential Experience Highlights for a Strong Regulator Assembler Resume

- Assembled and inspected pressure regulators, ensuring compliance with industry standards and client specifications.

- Utilized precision measuring instruments and specialized tools to calibrate and adjust regulator components.

- Analyzed technical drawings and specifications to identify and gather necessary components.

- Assembled and tested various types of regulators, including domeloaded, pilotoperated, and diaphragmtype regulators.

- Performed leak testing and functional checks on assembled regulators, ensuring proper operation and reliability.

- Identified and resolved assembly issues promptly, maintaining high production efficiency and minimizing downtime.

- Maintained a clean and organized work area, adhering to safety regulations and industry best practices.

Frequently Asked Questions (FAQ’s) For Regulator Assembler

What are the key skills required for a Regulator Assembler?

Key skills include regulator assembly, pneumatic tool operation, electronic component handling, blueprint reading, quality control procedures, and inspection techniques.

What industries employ Regulator Assemblers?

Regulator Assemblers are employed in various industries, including manufacturing, automotive, aerospace, and oil and gas.

What is the typical salary range for a Regulator Assembler?

The salary range for a Regulator Assembler can vary depending on experience, location, and industry. According to Indeed, the average salary for a Regulator Assembler in the United States is around $50,000 per year.

What are the career advancement opportunities for a Regulator Assembler?

With experience, Regulator Assemblers can advance to roles such as Quality Control Inspector, Manufacturing Supervisor, or Product Engineer.

What are the safety precautions that Regulator Assemblers should follow?

Regulator Assemblers should follow safety precautions such as wearing appropriate personal protective equipment, using tools and machinery correctly, and adhering to established safety protocols.

How can I improve my resume for a Regulator Assembler position?

To improve your resume, highlight your relevant skills and experience in regulator assembly, inspection, and testing. Use keywords from job descriptions and tailor your resume to each position you apply for.

What are the challenges faced by Regulator Assemblers?

Regulator Assemblers may face challenges such as meeting production deadlines, ensuring the accuracy and reliability of assembled regulators, and troubleshooting assembly issues.