Are you a seasoned Reliability Technologist seeking a new career path? Discover our professionally built Reliability Technologist Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

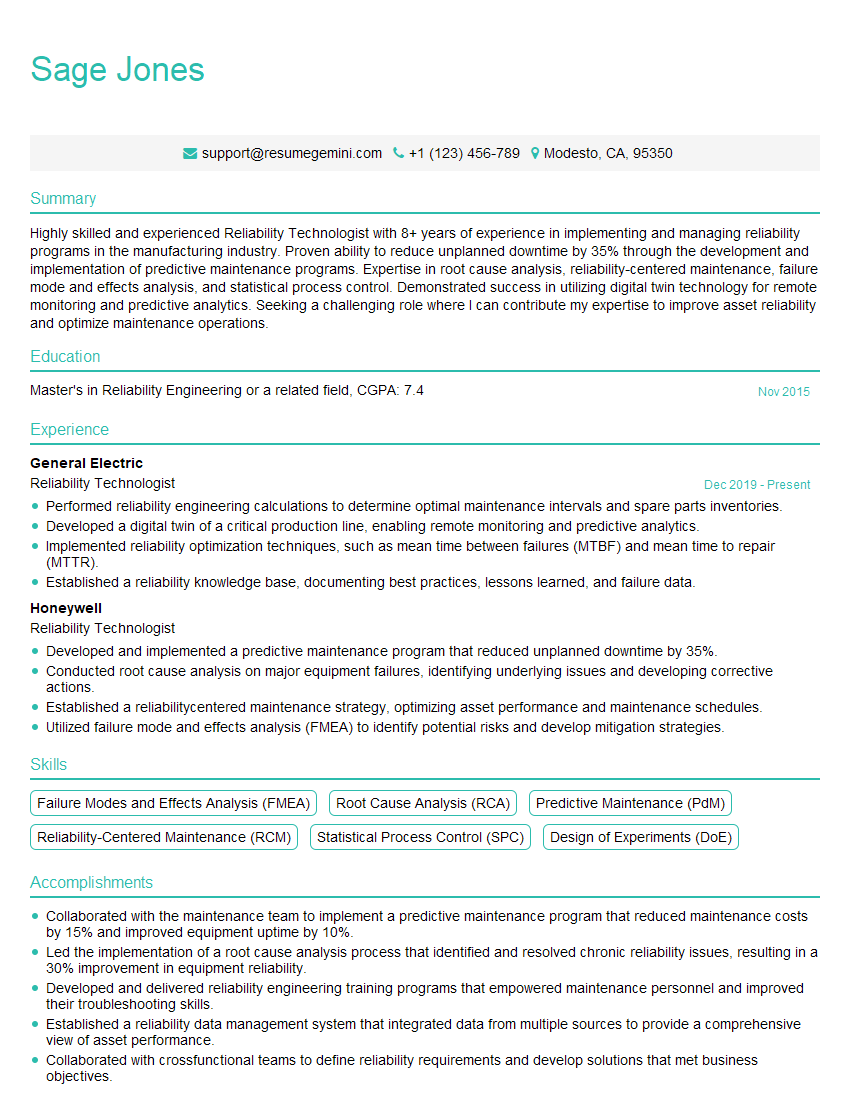

Sage Jones

Reliability Technologist

Summary

Highly skilled and experienced Reliability Technologist with 8+ years of experience in implementing and managing reliability programs in the manufacturing industry. Proven ability to reduce unplanned downtime by 35% through the development and implementation of predictive maintenance programs. Expertise in root cause analysis, reliability-centered maintenance, failure mode and effects analysis, and statistical process control. Demonstrated success in utilizing digital twin technology for remote monitoring and predictive analytics. Seeking a challenging role where I can contribute my expertise to improve asset reliability and optimize maintenance operations.

Education

Master’s in Reliability Engineering or a related field

November 2015

Skills

- Failure Modes and Effects Analysis (FMEA)

- Root Cause Analysis (RCA)

- Predictive Maintenance (PdM)

- Reliability-Centered Maintenance (RCM)

- Statistical Process Control (SPC)

- Design of Experiments (DoE)

Work Experience

Reliability Technologist

- Performed reliability engineering calculations to determine optimal maintenance intervals and spare parts inventories.

- Developed a digital twin of a critical production line, enabling remote monitoring and predictive analytics.

- Implemented reliability optimization techniques, such as mean time between failures (MTBF) and mean time to repair (MTTR).

- Established a reliability knowledge base, documenting best practices, lessons learned, and failure data.

Reliability Technologist

- Developed and implemented a predictive maintenance program that reduced unplanned downtime by 35%.

- Conducted root cause analysis on major equipment failures, identifying underlying issues and developing corrective actions.

- Established a reliabilitycentered maintenance strategy, optimizing asset performance and maintenance schedules.

- Utilized failure mode and effects analysis (FMEA) to identify potential risks and develop mitigation strategies.

Accomplishments

- Collaborated with the maintenance team to implement a predictive maintenance program that reduced maintenance costs by 15% and improved equipment uptime by 10%.

- Led the implementation of a root cause analysis process that identified and resolved chronic reliability issues, resulting in a 30% improvement in equipment reliability.

- Developed and delivered reliability engineering training programs that empowered maintenance personnel and improved their troubleshooting skills.

- Established a reliability data management system that integrated data from multiple sources to provide a comprehensive view of asset performance.

- Collaborated with crossfunctional teams to define reliability requirements and develop solutions that met business objectives.

Awards

- Received the Reliability Excellence Award for developing and implementing innovative reliability strategies that resulted in a 20% reduction in downtime.

- Recognized by the industry association for developing a reliability engineering framework that enhanced asset performance and reduced operating costs.

- Received a patent for a novel approach to reliability modeling and simulation that improved accuracy and reduced timetomarket.

- Honored as a Subject Matter Expert in the field of Reliability Technology by the IEEE.

Certificates

- Certified Maintenance and Reliability Professional (CMRP)

- Certified Reliability Engineer (CRE)

- Reliability Leader Professional (RLP)

- Certified Root Cause Analyst (CRCA)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Reliability Technologist

- Highlight your expertise in reliability engineering principles and methodologies, including failure mode and effects analysis (FMEA), root cause analysis (RCA), and reliability-centered maintenance (RCM).

- Quantify your accomplishments with specific metrics, such as the percentage reduction in unplanned downtime or the increase in asset uptime.

- Showcase your ability to utilize digital technologies, such as digital twins and predictive analytics, to improve reliability and maintenance operations.

- Demonstrate your knowledge of statistical process control (SPC) and design of experiments (DoE) techniques for reliability improvement.

- Emphasize your ability to work effectively in a team environment and collaborate with cross-functional stakeholders.

Essential Experience Highlights for a Strong Reliability Technologist Resume

- Develop and implement reliability programs to improve asset performance and reduce unplanned downtime.

- Conduct root cause analysis on major equipment failures to identify underlying issues and develop corrective actions.

- Establish reliability-centered maintenance strategies to optimize asset performance and maintenance schedules.

- Utilize failure mode and effects analysis (FMEA) to identify potential risks and develop mitigation strategies.

- Perform reliability engineering calculations to determine optimal maintenance intervals and spare parts inventories.

- Develop digital twins of critical production lines to enable remote monitoring and predictive analytics.

- Implement reliability optimization techniques, such as mean time between failures (MTBF) and mean time to repair (MTTR).

- Establish a reliability knowledge base to document best practices, lessons learned, and failure data.

Frequently Asked Questions (FAQ’s) For Reliability Technologist

What is the role of a Reliability Technologist?

A Reliability Technologist is responsible for developing and implementing reliability programs to improve asset performance, reduce unplanned downtime, and optimize maintenance operations.

What skills are required to be a successful Reliability Technologist?

Successful Reliability Technologists typically possess a strong understanding of reliability engineering principles, failure analysis techniques, and maintenance optimization strategies. They are also proficient in using digital technologies and statistical methods to improve reliability and maintenance operations.

What industries employ Reliability Technologists?

Reliability Technologists are employed in various industries, including manufacturing, energy, transportation, and healthcare, where asset reliability and uptime are critical to operational efficiency and safety.

What is the career path for a Reliability Technologist?

Reliability Technologists can advance their careers by taking on leadership roles in reliability engineering, maintenance management, or asset management. They can also specialize in specific areas, such as predictive maintenance or reliability engineering for complex systems.

What are the challenges faced by Reliability Technologists?

Reliability Technologists face challenges in dealing with complex and aging assets, increasing regulatory requirements, and the need to optimize maintenance operations in a cost-effective manner.

What are the emerging trends in Reliability Technology?

Emerging trends in Reliability Technology include the use of artificial intelligence (AI) and machine learning for predictive maintenance, the application of digital twins for remote monitoring and asset optimization, and the development of new reliability engineering methodologies for complex systems.