Are you a seasoned Repair Armature Winder Helper seeking a new career path? Discover our professionally built Repair Armature Winder Helper Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

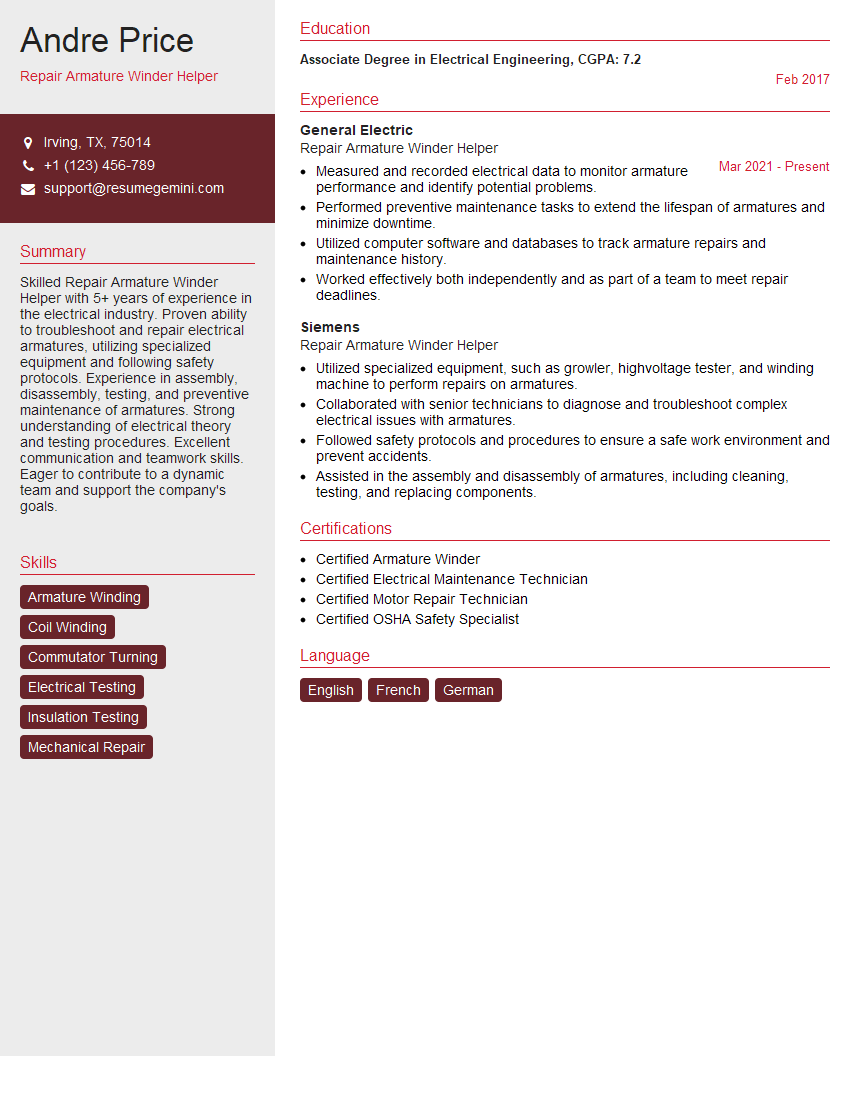

Andre Price

Repair Armature Winder Helper

Summary

Skilled Repair Armature Winder Helper with 5+ years of experience in the electrical industry. Proven ability to troubleshoot and repair electrical armatures, utilizing specialized equipment and following safety protocols. Experience in assembly, disassembly, testing, and preventive maintenance of armatures. Strong understanding of electrical theory and testing procedures. Excellent communication and teamwork skills. Eager to contribute to a dynamic team and support the company’s goals.

Education

Associate Degree in Electrical Engineering

February 2017

Skills

- Armature Winding

- Coil Winding

- Commutator Turning

- Electrical Testing

- Insulation Testing

- Mechanical Repair

Work Experience

Repair Armature Winder Helper

- Measured and recorded electrical data to monitor armature performance and identify potential problems.

- Performed preventive maintenance tasks to extend the lifespan of armatures and minimize downtime.

- Utilized computer software and databases to track armature repairs and maintenance history.

- Worked effectively both independently and as part of a team to meet repair deadlines.

Repair Armature Winder Helper

- Utilized specialized equipment, such as growler, highvoltage tester, and winding machine to perform repairs on armatures.

- Collaborated with senior technicians to diagnose and troubleshoot complex electrical issues with armatures.

- Followed safety protocols and procedures to ensure a safe work environment and prevent accidents.

- Assisted in the assembly and disassembly of armatures, including cleaning, testing, and replacing components.

Certificates

- Certified Armature Winder

- Certified Electrical Maintenance Technician

- Certified Motor Repair Technician

- Certified OSHA Safety Specialist

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Repair Armature Winder Helper

- Highlight your technical skills and experience in armature winding, coil winding, and electrical testing.

- Quantify your accomplishments whenever possible, using specific numbers and metrics.

- Emphasize your ability to work independently and as part of a team.

- Proofread your resume carefully for any errors in grammar or spelling.

Essential Experience Highlights for a Strong Repair Armature Winder Helper Resume

- Repair and maintain electrical armatures using specialized equipment and tools.

- Collaborate with senior technicians to diagnose and resolve electrical issues.

- Perform preventive maintenance tasks to extend the lifespan of armatures and minimize downtime.

- Ensure compliance with safety protocols and procedures to prevent accidents.

- Test and record electrical data to monitor armature performance and identify potential problems.

- Assist in the assembly and disassembly of armatures, including cleaning, testing, and replacing components.

Frequently Asked Questions (FAQ’s) For Repair Armature Winder Helper

What is the role of a Repair Armature Winder Helper?

A Repair Armature Winder Helper assists in the repair and maintenance of electrical armatures, which are essential components in various electrical devices and machinery.

What are the key skills required for this role?

Key skills for a Repair Armature Winder Helper include armature winding, coil winding, commutator turning, electrical testing, insulation testing, and mechanical repair.

What is the typical work environment for a Repair Armature Winder Helper?

Repair Armature Winder Helpers typically work in manufacturing facilities, repair shops, or industrial settings where electrical equipment is used and maintained.

What are the career advancement opportunities for a Repair Armature Winder Helper?

With experience and additional training, a Repair Armature Winder Helper can advance to roles such as Armature Winder, Electrical Technician, or Maintenance Supervisor.

What are the safety precautions that must be taken when working with electrical armatures?

Safety precautions for working with electrical armatures include wearing appropriate protective gear, following lockout/tagout procedures, and being aware of potential electrical hazards.

What are the common causes of armature failure?

Common causes of armature failure include wear and tear, overheating, insulation breakdown, and mechanical damage.

How can armature lifespan be extended?

Armature lifespan can be extended through proper maintenance, including regular cleaning, testing, and replacement of worn components.