Are you a seasoned Repair Miller seeking a new career path? Discover our professionally built Repair Miller Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

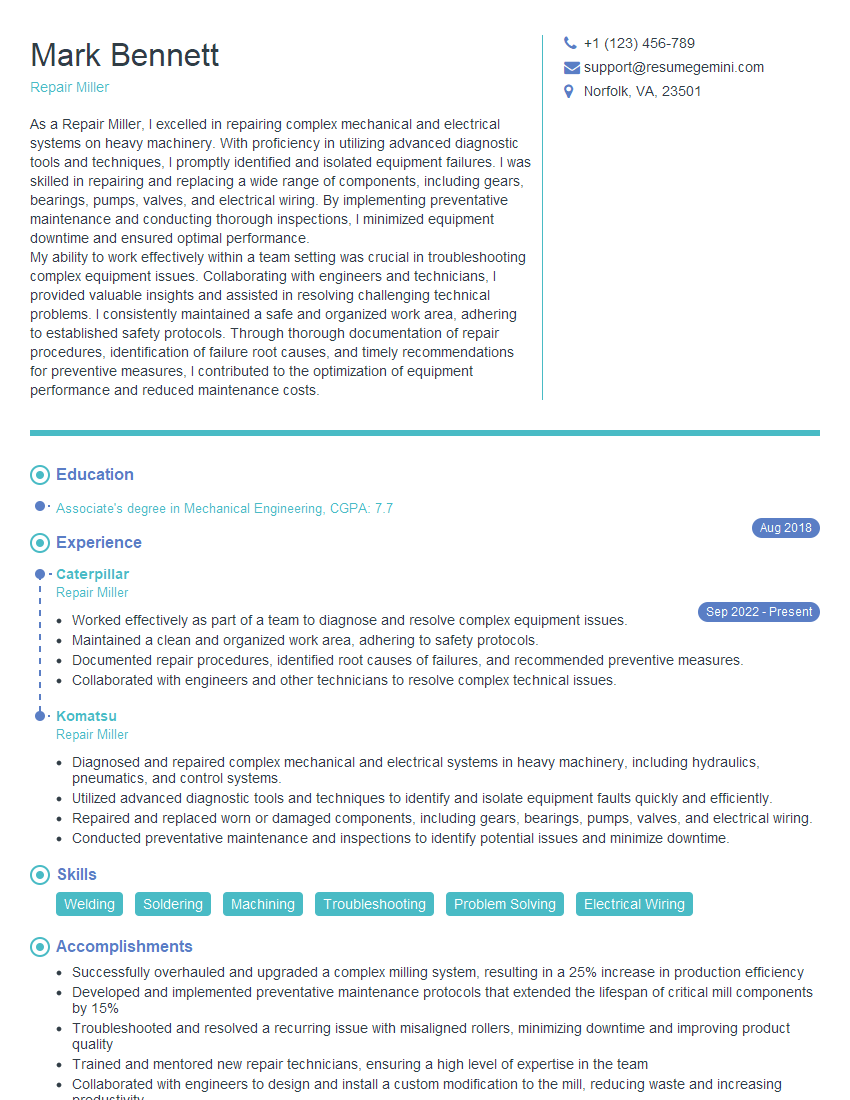

Mark Bennett

Repair Miller

Summary

As a Repair Miller, I excelled in repairing complex mechanical and electrical systems on heavy machinery. With proficiency in utilizing advanced diagnostic tools and techniques, I promptly identified and isolated equipment failures. I was skilled in repairing and replacing a wide range of components, including gears, bearings, pumps, valves, and electrical wiring. By implementing preventative maintenance and conducting thorough inspections, I minimized equipment downtime and ensured optimal performance.

My ability to work effectively within a team setting was crucial in troubleshooting complex equipment issues. Collaborating with engineers and technicians, I provided valuable insights and assisted in resolving challenging technical problems. I consistently maintained a safe and organized work area, adhering to established safety protocols. Through thorough documentation of repair procedures, identification of failure root causes, and timely recommendations for preventive measures, I contributed to the optimization of equipment performance and reduced maintenance costs.

Education

Associate’s degree in Mechanical Engineering

August 2018

Skills

- Welding

- Soldering

- Machining

- Troubleshooting

- Problem Solving

- Electrical Wiring

Work Experience

Repair Miller

- Worked effectively as part of a team to diagnose and resolve complex equipment issues.

- Maintained a clean and organized work area, adhering to safety protocols.

- Documented repair procedures, identified root causes of failures, and recommended preventive measures.

- Collaborated with engineers and other technicians to resolve complex technical issues.

Repair Miller

- Diagnosed and repaired complex mechanical and electrical systems in heavy machinery, including hydraulics, pneumatics, and control systems.

- Utilized advanced diagnostic tools and techniques to identify and isolate equipment faults quickly and efficiently.

- Repaired and replaced worn or damaged components, including gears, bearings, pumps, valves, and electrical wiring.

- Conducted preventative maintenance and inspections to identify potential issues and minimize downtime.

Accomplishments

- Successfully overhauled and upgraded a complex milling system, resulting in a 25% increase in production efficiency

- Developed and implemented preventative maintenance protocols that extended the lifespan of critical mill components by 15%

- Troubleshooted and resolved a recurring issue with misaligned rollers, minimizing downtime and improving product quality

- Trained and mentored new repair technicians, ensuring a high level of expertise in the team

- Collaborated with engineers to design and install a custom modification to the mill, reducing waste and increasing productivity

Awards

- Received the National Association of Repair Millers (NARM) Technician Excellence Award for Outstanding Proficiency in Mill Repair Techniques

- Recognized by the American Society of Mechanical Engineers (ASME) for innovative design enhancements in milling machinery

- Won the Regional Millwrights Competition for exceptional skill and precision in mill repair

- Received a commendation from the plant manager for exemplary troubleshooting and repair of a malfunctioning mill system

Certificates

- AWS Certified Welder

- ASME Certified Boiler and Pressure Vessel Inspector

- NCCER Certified Building Systems Mechanic

- OSHA 30-Hour Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Repair Miller

Tailor Your Resume to Each Job Description:

Highlight the skills and experience that are most relevant to the specific requirements of each job you apply for. Use specific examples from your work history to demonstrate your abilities.

Showcase Your Problem-Solving Abilities:

Repair Millers are often tasked with diagnosing and resolving complex equipment issues. Emphasize your analytical and problem-solving skills, providing examples of how you have successfully identified and fixed problems.

Quantify Your Accomplishments:

Whenever possible, quantify your accomplishments to provide tangible evidence of your impact. For example, you could mention the number of repairs you completed within a certain timeframe or the percentage of equipment downtime you reduced.

Use Industry-Specific Keywords:

Incorporate keywords that are commonly used in the repair industry. This will help your resume get noticed by potential employers who are using Applicant Tracking Systems (ATS) to screen candidates.

Essential Experience Highlights for a Strong Repair Miller Resume

- Diagnosed and repaired complex mechanical and electrical systems in heavy machinery.

- Utilized advanced diagnostic tools and techniques to identify and isolate equipment faults.

- Repaired and replaced worn or damaged components.

- Conducted preventative maintenance and inspections to identify potential issues and minimize downtime.

- Worked effectively as part of a team to diagnose and resolve complex equipment issues.

- Documented repair procedures, identified root causes of failures, and recommended preventive measures.

Frequently Asked Questions (FAQ’s) For Repair Miller

What are the primary qualifications for becoming a Repair Miller?

To be a successful Repair Miller, you typically need at least an associate’s degree in mechanical engineering or a related field. Additionally, you should have a strong understanding of mechanical and electrical systems, as well as experience with welding, soldering, and machining.

What are the career prospects for Repair Millers?

Repair Millers are in high demand in a variety of industries, including manufacturing, mining, and construction. With experience and additional certifications, you can advance to positions such as Maintenance Supervisor or Mechanical Engineer.

What are the key skills required for Repair Millers?

Repair Millers should possess strong problem-solving abilities, as well as proficiency in welding, soldering, machining, and electrical wiring. They should also be able to work independently and as part of a team, and have excellent communication and interpersonal skills.

What is the average salary for Repair Millers?

The average salary for Repair Millers varies depending on experience, location, and industry. According to the U.S. Bureau of Labor Statistics, the median annual salary for Millwrights in May 2021 was $55,720.

What are the job duties of a Repair Miller?

Repair Millers are responsible for diagnosing, repairing, and maintaining a variety of mechanical and electrical systems in heavy machinery. They also conduct preventative maintenance and inspections to identify potential issues and minimize downtime.

What are the safety precautions that Repair Millers should take?

Repair Millers should always wear appropriate safety gear, such as gloves, safety glasses, and earplugs. They should also be aware of the potential hazards associated with working with heavy machinery, and take steps to minimize the risk of injury.

What are the opportunities for professional development for Repair Millers?

Repair Millers can enhance their skills and knowledge through continuing education, attending workshops and conferences, and obtaining industry certifications. They can also seek opportunities to work on more complex equipment or take on leadership roles.