Are you a seasoned Resin Maker seeking a new career path? Discover our professionally built Resin Maker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

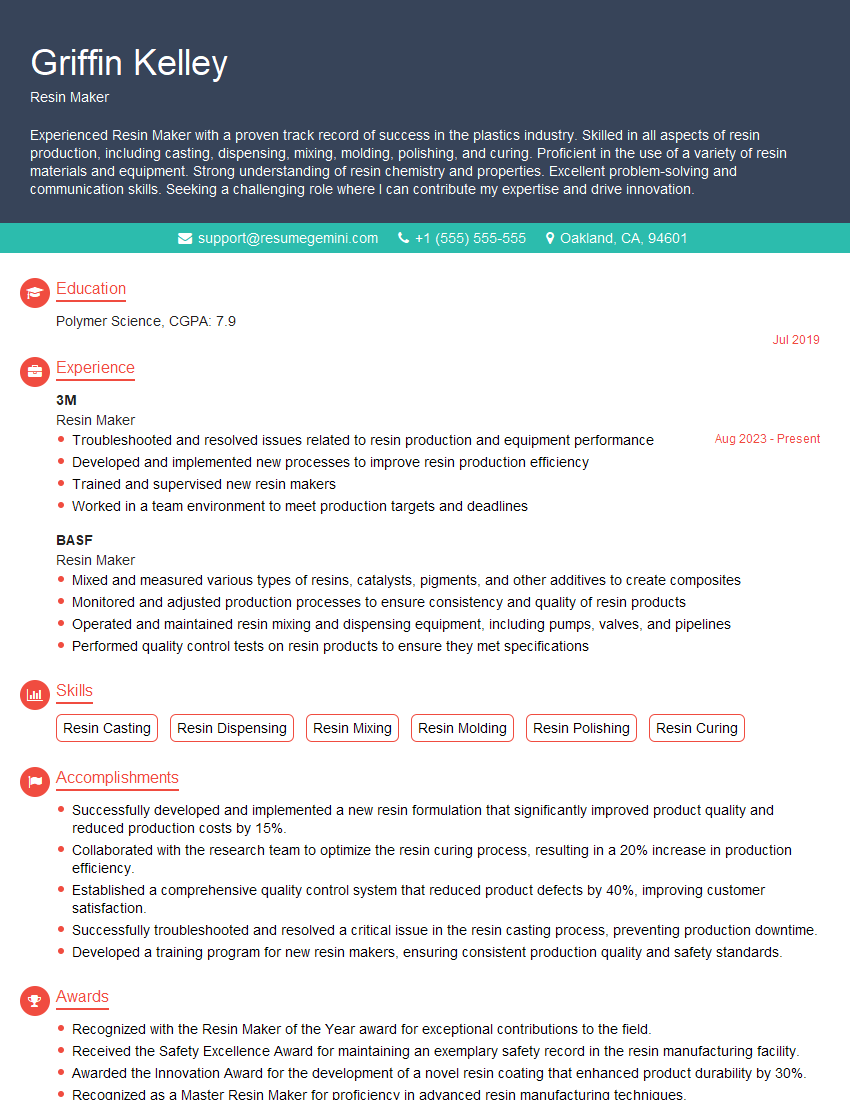

Griffin Kelley

Resin Maker

Summary

Experienced Resin Maker with a proven track record of success in the plastics industry. Skilled in all aspects of resin production, including casting, dispensing, mixing, molding, polishing, and curing. Proficient in the use of a variety of resin materials and equipment. Strong understanding of resin chemistry and properties. Excellent problem-solving and communication skills. Seeking a challenging role where I can contribute my expertise and drive innovation.

Education

Polymer Science

July 2019

Skills

- Resin Casting

- Resin Dispensing

- Resin Mixing

- Resin Molding

- Resin Polishing

- Resin Curing

Work Experience

Resin Maker

- Troubleshooted and resolved issues related to resin production and equipment performance

- Developed and implemented new processes to improve resin production efficiency

- Trained and supervised new resin makers

- Worked in a team environment to meet production targets and deadlines

Resin Maker

- Mixed and measured various types of resins, catalysts, pigments, and other additives to create composites

- Monitored and adjusted production processes to ensure consistency and quality of resin products

- Operated and maintained resin mixing and dispensing equipment, including pumps, valves, and pipelines

- Performed quality control tests on resin products to ensure they met specifications

Accomplishments

- Successfully developed and implemented a new resin formulation that significantly improved product quality and reduced production costs by 15%.

- Collaborated with the research team to optimize the resin curing process, resulting in a 20% increase in production efficiency.

- Established a comprehensive quality control system that reduced product defects by 40%, improving customer satisfaction.

- Successfully troubleshooted and resolved a critical issue in the resin casting process, preventing production downtime.

- Developed a training program for new resin makers, ensuring consistent production quality and safety standards.

Awards

- Recognized with the Resin Maker of the Year award for exceptional contributions to the field.

- Received the Safety Excellence Award for maintaining an exemplary safety record in the resin manufacturing facility.

- Awarded the Innovation Award for the development of a novel resin coating that enhanced product durability by 30%.

- Recognized as a Master Resin Maker for proficiency in advanced resin manufacturing techniques.

Certificates

- Society of Plastics Engineers (SPE) Certified Polymer Processing Specialist (CPPS)

- American Composites Manufacturers Association (ACMA) Certified Composites Technician (CCT)

- National Institute for Composite Technologies (NICoT) Certified Composite Technician (CCT)

- American Welding Society (AWS) Certified Welder (CWI)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Resin Maker

- Highlight your experience in the plastics industry and your knowledge of resin chemistry and properties.

- Showcase your skills in resin casting, dispensing, mixing, molding, polishing, and curing.

- Emphasize your proficiency in the use of a variety of resin materials and equipment.

- Demonstrate your strong problem-solving and communication skills.

Essential Experience Highlights for a Strong Resin Maker Resume

- Develop and implement processes for the production of high-quality resin products

- Operate and maintain resin production equipment

- Conduct quality control tests on resin products

- Troubleshoot and resolve production problems

- Train and supervise production staff

- Maintain a clean and safe work environment

Frequently Asked Questions (FAQ’s) For Resin Maker

What is the role of a Resin Maker?

A Resin Maker is responsible for the production of resin products. This involves developing and implementing processes for the production of high-quality resin products, operating and maintaining resin production equipment, conducting quality control tests on resin products, troubleshooting and resolving production problems, training and supervising production staff, and maintaining a clean and safe work environment.

What are the qualifications for a Resin Maker?

The qualifications for a Resin Maker typically include a degree in Polymer Science or a related field, as well as experience in the plastics industry and a strong understanding of resin chemistry and properties.

What are the skills required for a Resin Maker?

The skills required for a Resin Maker include proficiency in resin casting, dispensing, mixing, molding, polishing, and curing, as well as the ability to operate and maintain a variety of resin materials and equipment.

What are the career prospects for a Resin Maker?

The career prospects for a Resin Maker are good, with the demand for resin products expected to grow in the coming years.

What is the salary for a Resin Maker?

The salary for a Resin Maker can vary depending on experience, location, and employer. However, the average salary for a Resin Maker is around $50,000 per year.

What are the benefits of working as a Resin Maker?

The benefits of working as a Resin Maker can include a competitive salary, a variety of benefits, and the opportunity to work with a variety of people and materials.