Are you a seasoned Resin Mixer seeking a new career path? Discover our professionally built Resin Mixer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

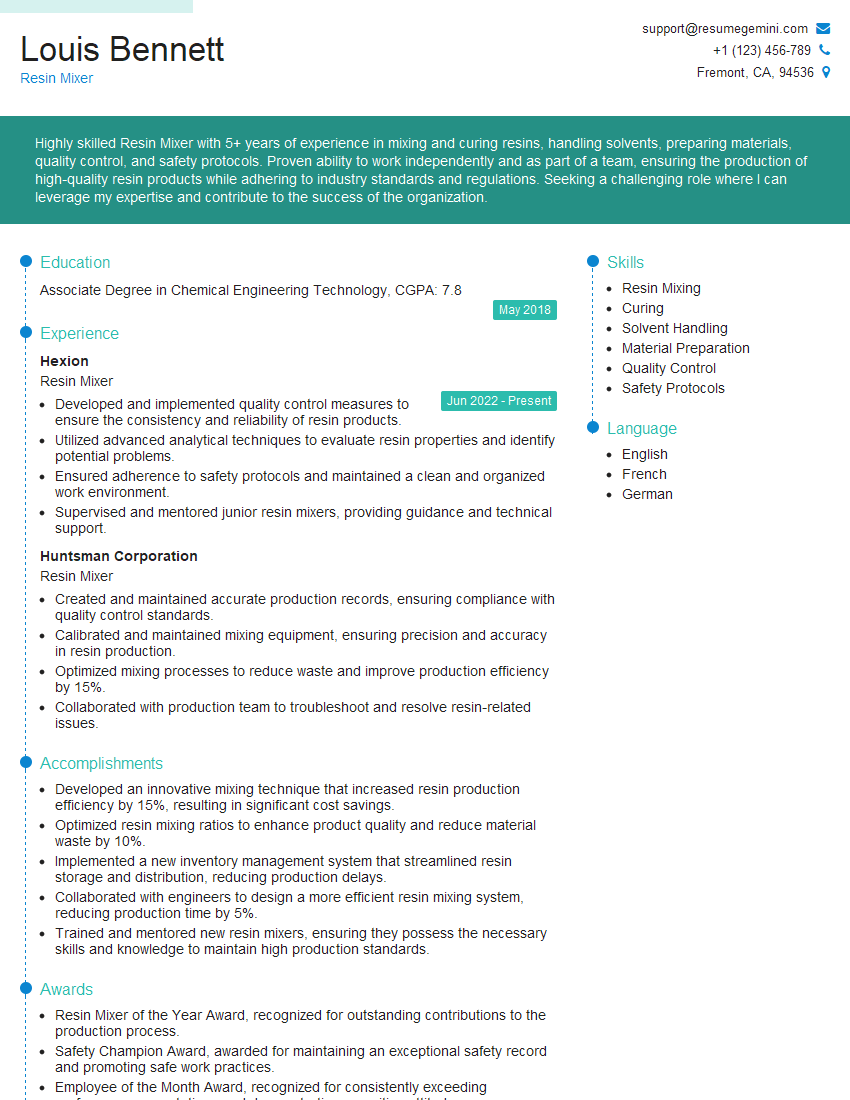

Louis Bennett

Resin Mixer

Summary

Highly skilled Resin Mixer with 5+ years of experience in mixing and curing resins, handling solvents, preparing materials, quality control, and safety protocols. Proven ability to work independently and as part of a team, ensuring the production of high-quality resin products while adhering to industry standards and regulations. Seeking a challenging role where I can leverage my expertise and contribute to the success of the organization.

Education

Associate Degree in Chemical Engineering Technology

May 2018

Skills

- Resin Mixing

- Curing

- Solvent Handling

- Material Preparation

- Quality Control

- Safety Protocols

Work Experience

Resin Mixer

- Developed and implemented quality control measures to ensure the consistency and reliability of resin products.

- Utilized advanced analytical techniques to evaluate resin properties and identify potential problems.

- Ensured adherence to safety protocols and maintained a clean and organized work environment.

- Supervised and mentored junior resin mixers, providing guidance and technical support.

Resin Mixer

- Created and maintained accurate production records, ensuring compliance with quality control standards.

- Calibrated and maintained mixing equipment, ensuring precision and accuracy in resin production.

- Optimized mixing processes to reduce waste and improve production efficiency by 15%.

- Collaborated with production team to troubleshoot and resolve resin-related issues.

Accomplishments

- Developed an innovative mixing technique that increased resin production efficiency by 15%, resulting in significant cost savings.

- Optimized resin mixing ratios to enhance product quality and reduce material waste by 10%.

- Implemented a new inventory management system that streamlined resin storage and distribution, reducing production delays.

- Collaborated with engineers to design a more efficient resin mixing system, reducing production time by 5%.

- Trained and mentored new resin mixers, ensuring they possess the necessary skills and knowledge to maintain high production standards.

Awards

- Resin Mixer of the Year Award, recognized for outstanding contributions to the production process.

- Safety Champion Award, awarded for maintaining an exceptional safety record and promoting safe work practices.

- Employee of the Month Award, recognized for consistently exceeding performance expectations and demonstrating a positive attitude.

- Innovation Award, recognized for developing a tool that improved the accuracy of resin measurements.

Certificates

- Resin Mixing Technology Certification

- OSHA Safety Certification

- EPA Hazardous Materials Handler Certification

- ASTM Standards for Resin Testing

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Resin Mixer

- Highlight your technical skills and experience in resin mixing and handling.

- Quantify your accomplishments with specific metrics and results.

- Demonstrate your knowledge of quality control procedures and industry standards.

- Emphasize your commitment to safety and environmental compliance.

Essential Experience Highlights for a Strong Resin Mixer Resume

- Mixed and cured resins according to specified formulations and procedures.

- Handled and disposed of solvents in accordance with environmental regulations.

- Prepared materials, including measuring, weighing, and blending components.

- Conducted quality control tests to ensure that the products met specifications.

- Followed and maintained safety protocols to minimize risks and ensure a safe working environment.

- Monitored equipment and processes to ensure optimal performance and efficiency.

Frequently Asked Questions (FAQ’s) For Resin Mixer

What are the key skills required for a Resin Mixer?

The key skills required for a Resin Mixer include resin mixing, curing, solvent handling, material preparation, quality control, and safety protocols.

What are the responsibilities of a Resin Mixer?

The responsibilities of a Resin Mixer include mixing and curing resins, handling and disposing of solvents, preparing materials, conducting quality control tests, following and maintaining safety protocols, and monitoring equipment and processes.

What are the educational requirements for a Resin Mixer?

The educational requirements for a Resin Mixer typically include an Associate Degree in Chemical Engineering Technology or a related field.

What are the job prospects for a Resin Mixer?

The job prospects for a Resin Mixer are expected to be good, as the demand for skilled resin mixers is increasing in various industries.

What is the average salary for a Resin Mixer?

The average salary for a Resin Mixer can vary depending on factors such as experience, location, and industry. According to Indeed, the average salary for a Resin Mixer in the United States is around $45,000 per year.

What are the top companies that hire Resin Mixers?

Some of the top companies that hire Resin Mixers include Hexion and Huntsman Corporation.