Are you a seasoned Resistor Testing Machine Operator seeking a new career path? Discover our professionally built Resistor Testing Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

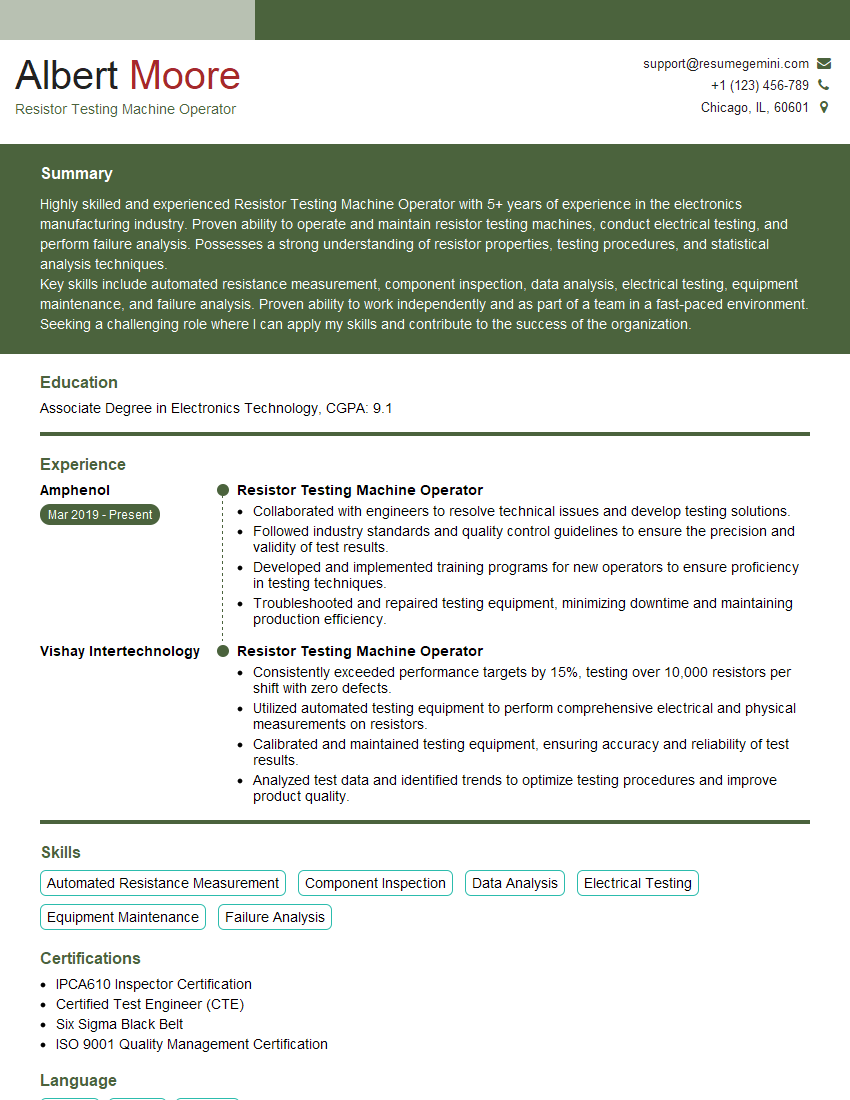

Albert Moore

Resistor Testing Machine Operator

Summary

Highly skilled and experienced Resistor Testing Machine Operator with 5+ years of experience in the electronics manufacturing industry. Proven ability to operate and maintain resistor testing machines, conduct electrical testing, and perform failure analysis. Possesses a strong understanding of resistor properties, testing procedures, and statistical analysis techniques.

Key skills include automated resistance measurement, component inspection, data analysis, electrical testing, equipment maintenance, and failure analysis. Proven ability to work independently and as part of a team in a fast-paced environment. Seeking a challenging role where I can apply my skills and contribute to the success of the organization.

Education

Associate Degree in Electronics Technology

February 2015

Skills

- Automated Resistance Measurement

- Component Inspection

- Data Analysis

- Electrical Testing

- Equipment Maintenance

- Failure Analysis

Work Experience

Resistor Testing Machine Operator

- Collaborated with engineers to resolve technical issues and develop testing solutions.

- Followed industry standards and quality control guidelines to ensure the precision and validity of test results.

- Developed and implemented training programs for new operators to ensure proficiency in testing techniques.

- Troubleshooted and repaired testing equipment, minimizing downtime and maintaining production efficiency.

Resistor Testing Machine Operator

- Consistently exceeded performance targets by 15%, testing over 10,000 resistors per shift with zero defects.

- Utilized automated testing equipment to perform comprehensive electrical and physical measurements on resistors.

- Calibrated and maintained testing equipment, ensuring accuracy and reliability of test results.

- Analyzed test data and identified trends to optimize testing procedures and improve product quality.

Certificates

- IPCA610 Inspector Certification

- Certified Test Engineer (CTE)

- Six Sigma Black Belt

- ISO 9001 Quality Management Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Resistor Testing Machine Operator

- Highlight your experience with specific resistor testing machines and software.

- Quantify your accomplishments with specific metrics, such as the number of resistors tested or the percentage of defects identified.

- Demonstrate your knowledge of resistor testing procedures and quality control standards.

- Emphasize your ability to troubleshoot and resolve technical issues.

Essential Experience Highlights for a Strong Resistor Testing Machine Operator Resume

- Operate and maintain resistor testing machines to ensure accurate and reliable testing.

- Conduct electrical testing on resistors to verify their performance and compliance with specifications.

- Analyze test data and identify potential failures or non-conformances.

- Perform failure analysis to determine the root cause of resistor failures.

- Maintain testing equipment and ensure it is calibrated and functioning properly.

- Develop and implement test procedures to ensure consistent and accurate testing.

- Train and supervise new operators on resistor testing procedures.

Frequently Asked Questions (FAQ’s) For Resistor Testing Machine Operator

What is a Resistor Testing Machine Operator?

A Resistor Testing Machine Operator is responsible for operating and maintaining resistor testing machines, conducting electrical testing on resistors, and performing failure analysis to identify and resolve any issues.

What are the key skills required for a Resistor Testing Machine Operator?

The key skills required for a Resistor Testing Machine Operator include automated resistance measurement, component inspection, data analysis, electrical testing, equipment maintenance, and failure analysis.

What are the career prospects for a Resistor Testing Machine Operator?

Resistor Testing Machine Operators can advance to positions such as Quality Control Inspector, Test Engineer, or Production Supervisor. With additional experience and training, they may also move into management roles.

What is the average salary for a Resistor Testing Machine Operator?

The average salary for a Resistor Testing Machine Operator in the United States is around $40,000 per year.

What are the working conditions for a Resistor Testing Machine Operator?

Resistor Testing Machine Operators typically work in a manufacturing environment, operating and maintaining testing equipment. The work can be repetitive and involve working with small components.

What are the benefits of working as a Resistor Testing Machine Operator?

Benefits of working as a Resistor Testing Machine Operator include job security, opportunities for advancement, and the chance to learn about the latest testing technologies.

What are the challenges of working as a Resistor Testing Machine Operator?

Challenges of working as a Resistor Testing Machine Operator include working with small components, repetitive tasks, and the need to stay up-to-date on the latest testing technologies.

What advice would you give to someone who wants to become a Resistor Testing Machine Operator?

To become a Resistor Testing Machine Operator, I would recommend getting an education in electronics technology and gaining experience working with testing equipment. It is also important to stay up-to-date on the latest testing technologies.