Are you a seasoned Rivet Machine Operator seeking a new career path? Discover our professionally built Rivet Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

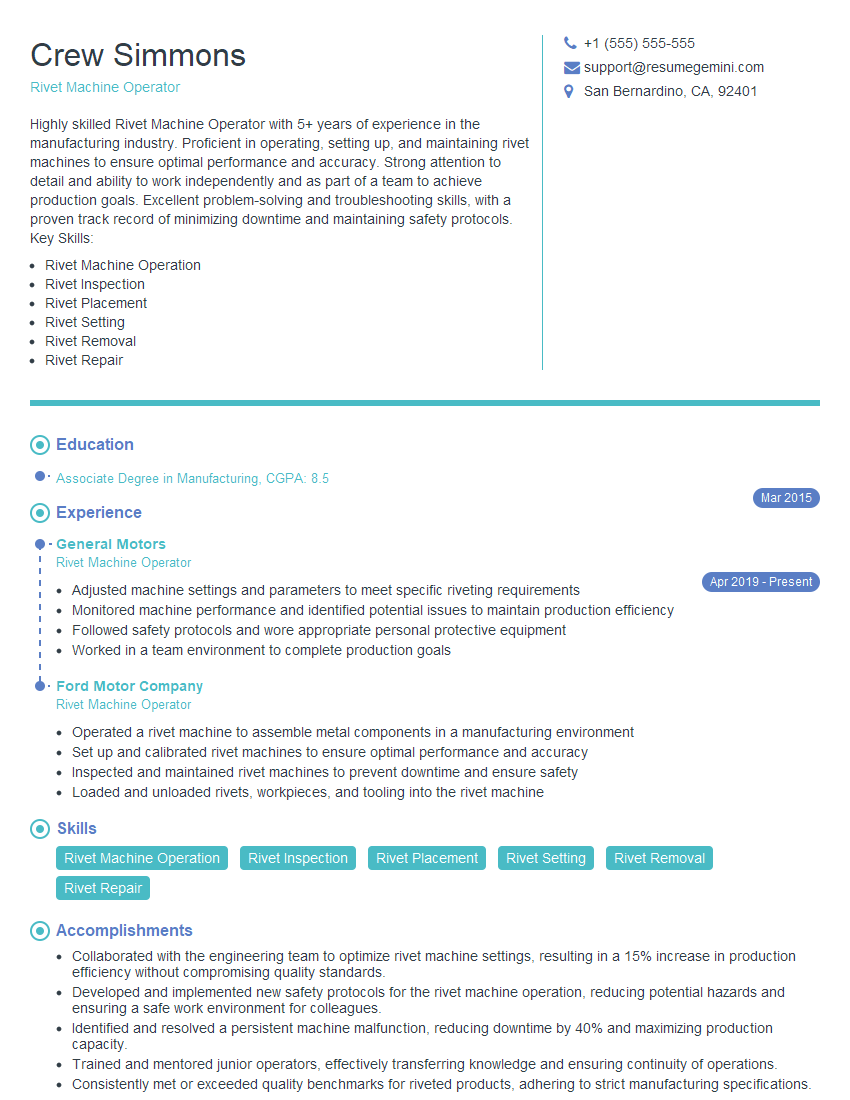

Crew Simmons

Rivet Machine Operator

Summary

Highly skilled Rivet Machine Operator with 5+ years of experience in the manufacturing industry. Proficient in operating, setting up, and maintaining rivet machines to ensure optimal performance and accuracy. Strong attention to detail and ability to work independently and as part of a team to achieve production goals. Excellent problem-solving and troubleshooting skills, with a proven track record of minimizing downtime and maintaining safety protocols.

Key Skills:

- Rivet Machine Operation

- Rivet Inspection

- Rivet Placement

- Rivet Setting

- Rivet Removal

- Rivet Repair

Education

Associate Degree in Manufacturing

March 2015

Skills

- Rivet Machine Operation

- Rivet Inspection

- Rivet Placement

- Rivet Setting

- Rivet Removal

- Rivet Repair

Work Experience

Rivet Machine Operator

- Adjusted machine settings and parameters to meet specific riveting requirements

- Monitored machine performance and identified potential issues to maintain production efficiency

- Followed safety protocols and wore appropriate personal protective equipment

- Worked in a team environment to complete production goals

Rivet Machine Operator

- Operated a rivet machine to assemble metal components in a manufacturing environment

- Set up and calibrated rivet machines to ensure optimal performance and accuracy

- Inspected and maintained rivet machines to prevent downtime and ensure safety

- Loaded and unloaded rivets, workpieces, and tooling into the rivet machine

Accomplishments

- Collaborated with the engineering team to optimize rivet machine settings, resulting in a 15% increase in production efficiency without compromising quality standards.

- Developed and implemented new safety protocols for the rivet machine operation, reducing potential hazards and ensuring a safe work environment for colleagues.

- Identified and resolved a persistent machine malfunction, reducing downtime by 40% and maximizing production capacity.

- Trained and mentored junior operators, effectively transferring knowledge and ensuring continuity of operations.

- Consistently met or exceeded quality benchmarks for riveted products, adhering to strict manufacturing specifications.

Certificates

- Rivet Machine Operator Certification

- Rivet Machine Maintenance Certification

- Rivet Machine Safety Certification

- Rivet Machine Quality Control Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Rivet Machine Operator

- Quantify your accomplishments: Use numbers and metrics to demonstrate the impact of your contributions.

- Highlight your technical skills: Emphasize your proficiency in operating and maintaining rivet machines.

- Showcase your problem-solving abilities: Describe situations where you identified and resolved machine issues, resulting in improved productivity.

- Demonstrate your teamwork and collaboration skills: Explain how you effectively worked with colleagues to achieve team goals.

Essential Experience Highlights for a Strong Rivet Machine Operator Resume

- Set up and calibrated rivet machines to ensure optimal performance and accuracy

- Loaded and unloaded rivets, workpieces, and tooling into the rivet machine

- Inspected and maintained rivet machines to prevent downtime and ensure safety

- Adjusted machine settings and parameters to meet specific riveting requirements

- Monitored machine performance and identified potential issues to maintain production efficiency

- Followed safety protocols and wore appropriate personal protective equipment

- Worked in a team environment to complete production goals

Frequently Asked Questions (FAQ’s) For Rivet Machine Operator

What is the primary function of a Rivet Machine Operator?

The primary function of a Rivet Machine Operator is to operate, set up, and maintain rivet machines to assemble metal components in a manufacturing environment.

What are the key skills required for a Rivet Machine Operator?

Key skills for a Rivet Machine Operator include rivet machine operation, rivet inspection, rivet placement, rivet setting, rivet removal, rivet repair, and attention to detail.

What is the average salary for a Rivet Machine Operator?

The average salary for a Rivet Machine Operator varies depending on experience, location, and company size, but typically ranges from $35,000 to $55,000 per year.

What are the career advancement opportunities for a Rivet Machine Operator?

Career advancement opportunities for a Rivet Machine Operator may include becoming a Rivet Machine Supervisor, a Quality Control Inspector, or a Manufacturing Engineer.

What are the safety protocols that a Rivet Machine Operator must follow?

Rivet Machine Operators must follow safety protocols such as wearing appropriate personal protective equipment, following lockout/tagout procedures, and maintaining a clean and organized work area.

What is the role of a Rivet Machine Operator in a manufacturing environment?

Rivet Machine Operators play a crucial role in the manufacturing process by ensuring that metal components are securely and accurately assembled using rivet machines.