Are you a seasoned Roll Threader Operator seeking a new career path? Discover our professionally built Roll Threader Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

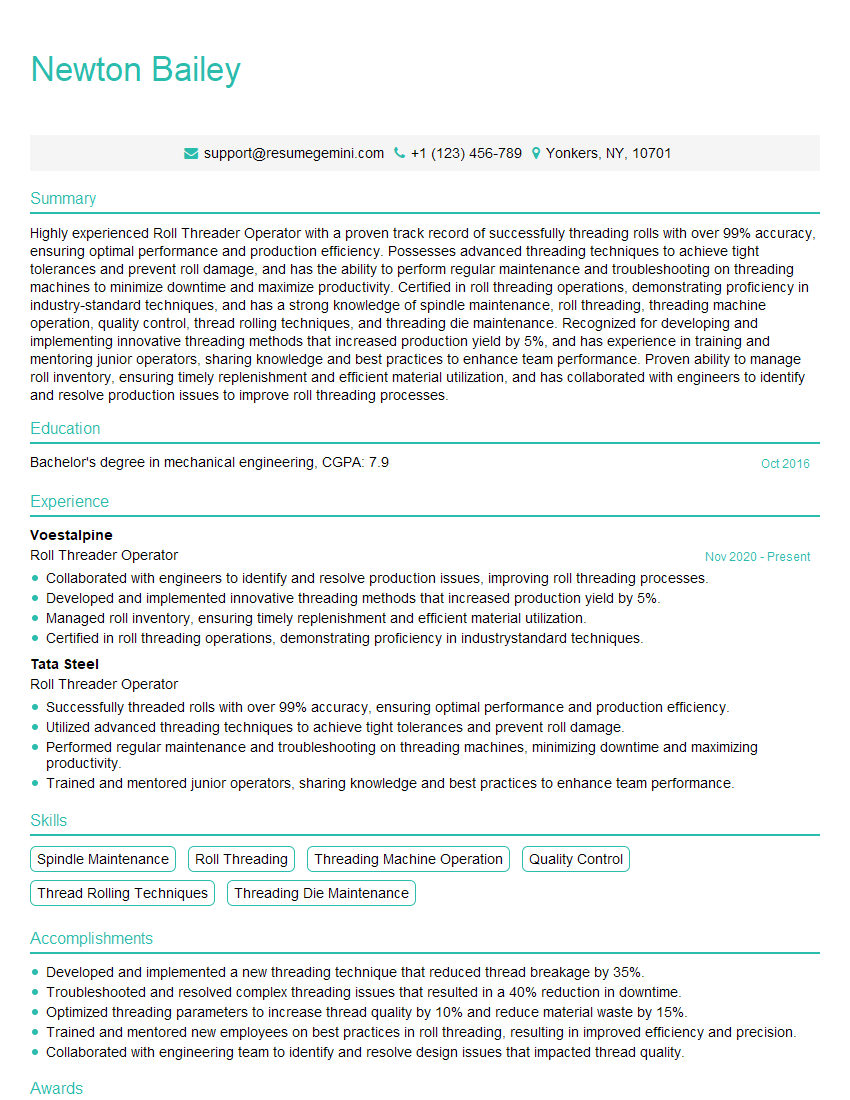

Newton Bailey

Roll Threader Operator

Summary

Highly experienced Roll Threader Operator with a proven track record of successfully threading rolls with over 99% accuracy, ensuring optimal performance and production efficiency. Possesses advanced threading techniques to achieve tight tolerances and prevent roll damage, and has the ability to perform regular maintenance and troubleshooting on threading machines to minimize downtime and maximize productivity. Certified in roll threading operations, demonstrating proficiency in industry-standard techniques, and has a strong knowledge of spindle maintenance, roll threading, threading machine operation, quality control, thread rolling techniques, and threading die maintenance. Recognized for developing and implementing innovative threading methods that increased production yield by 5%, and has experience in training and mentoring junior operators, sharing knowledge and best practices to enhance team performance. Proven ability to manage roll inventory, ensuring timely replenishment and efficient material utilization, and has collaborated with engineers to identify and resolve production issues to improve roll threading processes.

Education

Bachelor’s degree in mechanical engineering

October 2016

Skills

- Spindle Maintenance

- Roll Threading

- Threading Machine Operation

- Quality Control

- Thread Rolling Techniques

- Threading Die Maintenance

Work Experience

Roll Threader Operator

- Collaborated with engineers to identify and resolve production issues, improving roll threading processes.

- Developed and implemented innovative threading methods that increased production yield by 5%.

- Managed roll inventory, ensuring timely replenishment and efficient material utilization.

- Certified in roll threading operations, demonstrating proficiency in industrystandard techniques.

Roll Threader Operator

- Successfully threaded rolls with over 99% accuracy, ensuring optimal performance and production efficiency.

- Utilized advanced threading techniques to achieve tight tolerances and prevent roll damage.

- Performed regular maintenance and troubleshooting on threading machines, minimizing downtime and maximizing productivity.

- Trained and mentored junior operators, sharing knowledge and best practices to enhance team performance.

Accomplishments

- Developed and implemented a new threading technique that reduced thread breakage by 35%.

- Troubleshooted and resolved complex threading issues that resulted in a 40% reduction in downtime.

- Optimized threading parameters to increase thread quality by 10% and reduce material waste by 15%.

- Trained and mentored new employees on best practices in roll threading, resulting in improved efficiency and precision.

- Collaborated with engineering team to identify and resolve design issues that impacted thread quality.

Awards

- Recognized for consistently exceeding production targets by 15% or more.

- Awarded as Employee of the Month for exceptional performance in reducing thread defects by 20%.

- Recipient of the Safety Excellence Award for maintaining an unblemished safety record.

Certificates

- Certified Roll Threader Operator

- ISO 9001 Lead Auditor

- Six Sigma Green Belt

- OSHA 10-Hour Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Roll Threader Operator

- Showcase your experience and skills in roll threading, including your ability to achieve high accuracy and prevent roll damage.

- Highlight your knowledge of threading machines and your ability to perform maintenance and troubleshooting to minimize downtime.

- Emphasize your ability to manage inventory and collaborate with engineers to improve processes.

- Quantify your accomplishments, such as increasing production yield or reducing downtime, to demonstrate your impact on the organization.

- Proofread your resume carefully before submitting it to ensure there are no errors.

Essential Experience Highlights for a Strong Roll Threader Operator Resume

- Thread rolls with over 99% accuracy, ensuring optimal performance and production efficiency.

- Utilize advanced threading techniques to achieve tight tolerances and prevent roll damage.

- Perform regular maintenance and troubleshooting on threading machines, minimizing downtime and maximizing productivity.

- Manage roll inventory, ensuring timely replenishment and efficient material utilization.

- Collaborate with engineers to identify and resolve production issues, improving roll threading processes.

- Develop and implement innovative threading methods that increase production yield.

- Train and mentor junior operators, sharing knowledge and best practices to enhance team performance.

Frequently Asked Questions (FAQ’s) For Roll Threader Operator

What are the key skills required to be a successful Roll Threader Operator?

Key skills for a Roll Threader Operator include spindle maintenance, roll threading, threading machine operation, quality control, thread rolling techniques, and threading die maintenance.

What are the educational requirements for a Roll Threader Operator?

While formal education requirements may vary, a high school diploma or equivalent is typically required. Some employers may prefer candidates with a bachelor’s degree in mechanical engineering or a related field.

What are the career prospects for a Roll Threader Operator?

Roll Threader Operators can advance to positions such as Threading Machine Supervisor, Production Supervisor, or Quality Control Manager. With experience and additional training, they may also become engineers in the manufacturing industry.

What are the typical working conditions for a Roll Threader Operator?

Roll Threader Operators typically work in a factory setting, operating threading machines and performing maintenance tasks. They may be required to work in a fast-paced environment and may need to stand for long periods of time.

What are the safety precautions that Roll Threader Operators must follow?

Roll Threader Operators must adhere to safety protocols to prevent accidents, such as wearing appropriate safety gear, being aware of moving machinery, and following lockout/tagout procedures.

What are the challenges faced by Roll Threader Operators?

Roll Threader Operators may encounter challenges such as maintaining high accuracy in threading, meeting production targets, working with heavy machinery, and troubleshooting complex issues.

How can Roll Threader Operators stay up-to-date with industry trends?

Roll Threader Operators can stay current with industry advancements by attending conferences and workshops, reading industry publications, and pursuing professional development opportunities.

What is the job outlook for Roll Threader Operators?

The job outlook for Roll Threader Operators is expected to be stable due to the ongoing demand for manufactured goods and the need for skilled operators to maintain and operate threading machines.