Are you a seasoned Rolls Mill Operator seeking a new career path? Discover our professionally built Rolls Mill Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

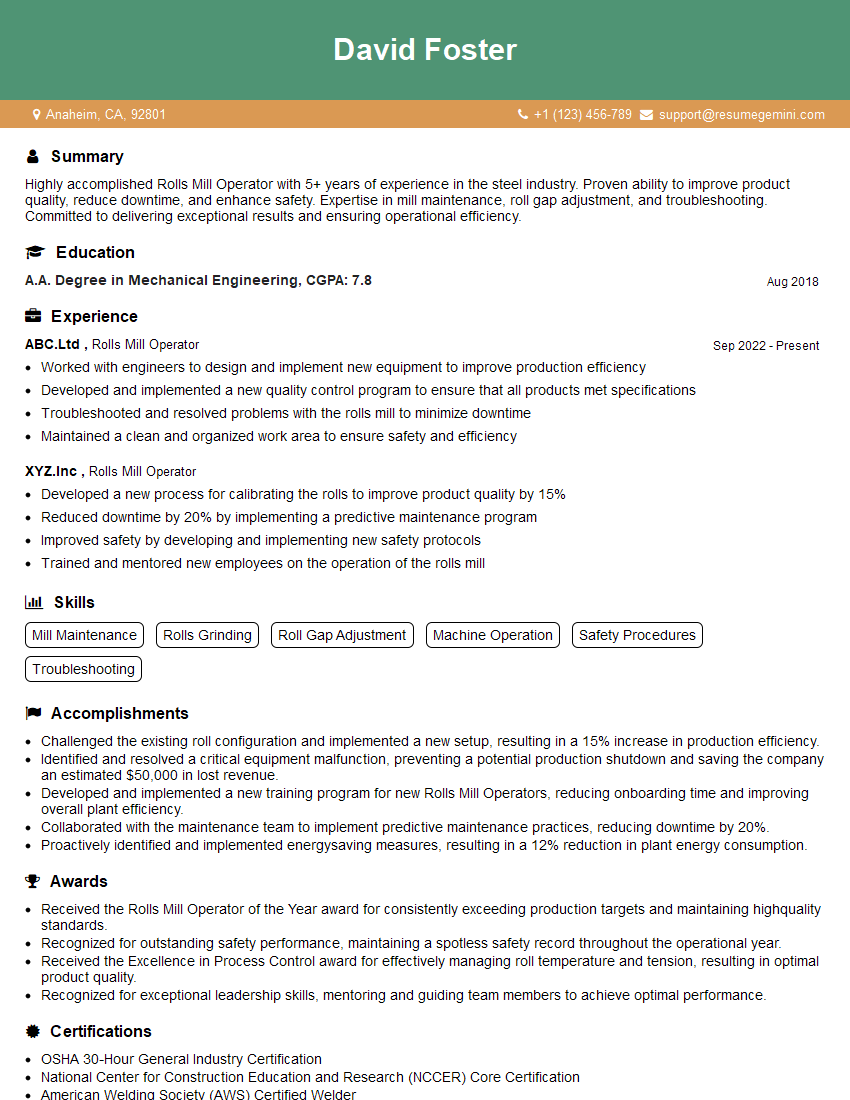

David Foster

Rolls Mill Operator

Summary

Highly accomplished Rolls Mill Operator with 5+ years of experience in the steel industry. Proven ability to improve product quality, reduce downtime, and enhance safety. Expertise in mill maintenance, roll gap adjustment, and troubleshooting. Committed to delivering exceptional results and ensuring operational efficiency.

Education

A.A. Degree in Mechanical Engineering

August 2018

Skills

- Mill Maintenance

- Rolls Grinding

- Roll Gap Adjustment

- Machine Operation

- Safety Procedures

- Troubleshooting

Work Experience

Rolls Mill Operator

- Worked with engineers to design and implement new equipment to improve production efficiency

- Developed and implemented a new quality control program to ensure that all products met specifications

- Troubleshooted and resolved problems with the rolls mill to minimize downtime

- Maintained a clean and organized work area to ensure safety and efficiency

Rolls Mill Operator

- Developed a new process for calibrating the rolls to improve product quality by 15%

- Reduced downtime by 20% by implementing a predictive maintenance program

- Improved safety by developing and implementing new safety protocols

- Trained and mentored new employees on the operation of the rolls mill

Accomplishments

- Challenged the existing roll configuration and implemented a new setup, resulting in a 15% increase in production efficiency.

- Identified and resolved a critical equipment malfunction, preventing a potential production shutdown and saving the company an estimated $50,000 in lost revenue.

- Developed and implemented a new training program for new Rolls Mill Operators, reducing onboarding time and improving overall plant efficiency.

- Collaborated with the maintenance team to implement predictive maintenance practices, reducing downtime by 20%.

- Proactively identified and implemented energysaving measures, resulting in a 12% reduction in plant energy consumption.

Awards

- Received the Rolls Mill Operator of the Year award for consistently exceeding production targets and maintaining highquality standards.

- Recognized for outstanding safety performance, maintaining a spotless safety record throughout the operational year.

- Received the Excellence in Process Control award for effectively managing roll temperature and tension, resulting in optimal product quality.

- Recognized for exceptional leadership skills, mentoring and guiding team members to achieve optimal performance.

Certificates

- OSHA 30-Hour General Industry Certification

- National Center for Construction Education and Research (NCCER) Core Certification

- American Welding Society (AWS) Certified Welder

- National Institute for Metalworking Skills (NIMS) Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Rolls Mill Operator

- Highlight your technical skills and experience in rolls mill operation and maintenance.

- Quantify your accomplishments with specific metrics to demonstrate your impact on the organization.

- Showcase your commitment to safety and adherence to industry regulations.

- Emphasize your ability to work independently and as part of a team.

- Proofread your resume carefully for any errors or omissions.

Essential Experience Highlights for a Strong Rolls Mill Operator Resume

- Operate and maintain rolls mills to produce high-quality steel products.

- Calibrate and adjust rolls to achieve optimal performance and product specifications.

- Implement preventive maintenance programs to minimize downtime and ensure smooth operation.

- Troubleshoot and resolve equipment malfunctions to maximize production efficiency.

- Monitor and control production processes to ensure adherence to quality standards.

- Train and supervise new employees on rolls mill operation and safety procedures.

- Collaborate with engineers to improve equipment design and optimize production processes.

Frequently Asked Questions (FAQ’s) For Rolls Mill Operator

What is the primary role of a Rolls Mill Operator?

A Rolls Mill Operator is responsible for operating and maintaining rolls mills, calibrating and adjusting rolls, implementing preventive maintenance programs, troubleshooting and resolving equipment malfunctions, and monitoring and controlling production processes to ensure adherence to quality standards.

What qualifications are required to become a Rolls Mill Operator?

A Rolls Mill Operator typically requires an A.A. Degree in Mechanical Engineering or a related field, along with hands-on experience in rolls mill operation and maintenance. Industry certifications and training programs can also enhance your qualifications.

What are the key skills needed to be successful as a Rolls Mill Operator?

Key skills for a Rolls Mill Operator include mill maintenance, roll gap adjustment, machine operation, safety procedures, troubleshooting, and attention to detail.

What are the career prospects for a Rolls Mill Operator?

With experience and additional training, a Rolls Mill Operator can advance to roles such as Rolls Mill Supervisor, Production Manager, or Maintenance Manager.

What is the work environment like for a Rolls Mill Operator?

Rolls Mill Operators typically work in industrial settings, operating and maintaining rolls mills. The work can be physically demanding and may involve exposure to noise and hazardous materials.

What are the safety precautions that Rolls Mill Operators must follow?

Rolls Mill Operators must adhere to strict safety protocols, including wearing appropriate protective gear, following lockout/tagout procedures, and maintaining a clean and organized work area.

How can I improve my chances of getting hired as a Rolls Mill Operator?

To improve your chances of getting hired as a Rolls Mill Operator, obtain the necessary qualifications, develop your skills through hands-on experience or training programs, and highlight your commitment to safety and quality in your resume and job applications.