Are you a seasoned Rotary Lithographic Press Operator seeking a new career path? Discover our professionally built Rotary Lithographic Press Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

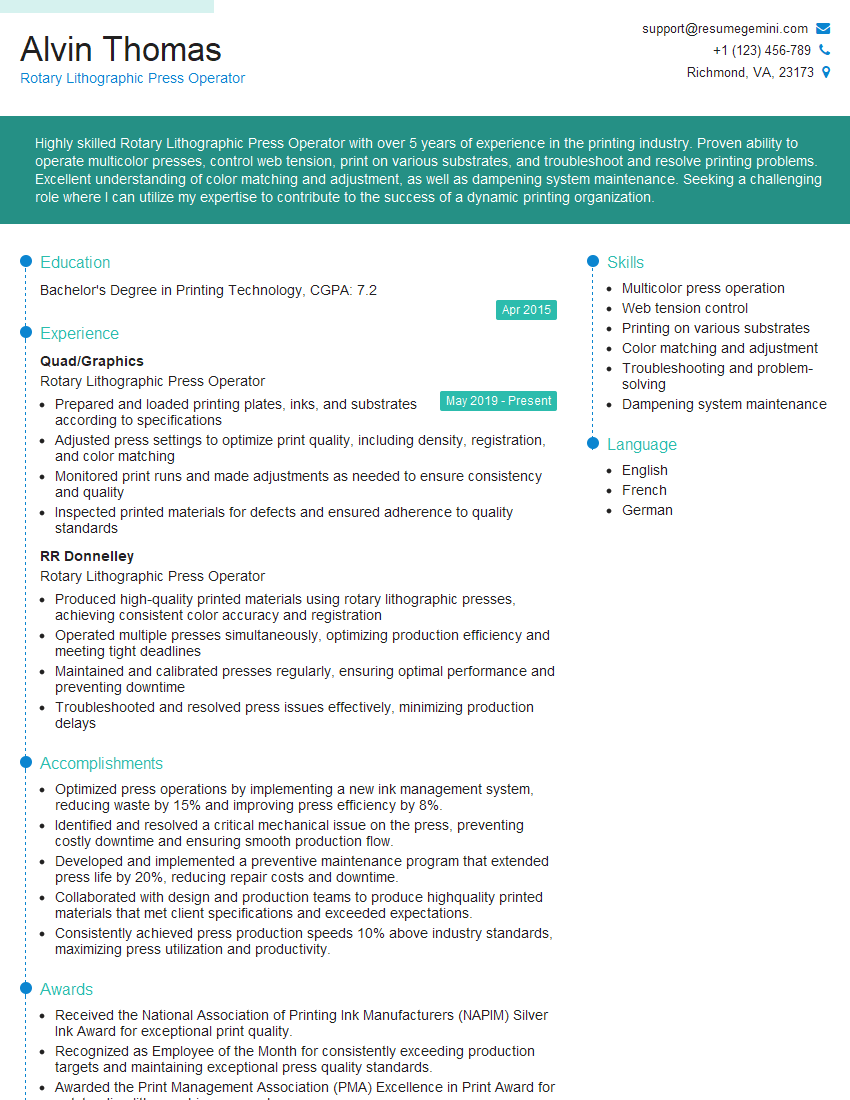

Alvin Thomas

Rotary Lithographic Press Operator

Summary

Highly skilled Rotary Lithographic Press Operator with over 5 years of experience in the printing industry. Proven ability to operate multicolor presses, control web tension, print on various substrates, and troubleshoot and resolve printing problems. Excellent understanding of color matching and adjustment, as well as dampening system maintenance. Seeking a challenging role where I can utilize my expertise to contribute to the success of a dynamic printing organization.

Education

Bachelor’s Degree in Printing Technology

April 2015

Skills

- Multicolor press operation

- Web tension control

- Printing on various substrates

- Color matching and adjustment

- Troubleshooting and problem-solving

- Dampening system maintenance

Work Experience

Rotary Lithographic Press Operator

- Prepared and loaded printing plates, inks, and substrates according to specifications

- Adjusted press settings to optimize print quality, including density, registration, and color matching

- Monitored print runs and made adjustments as needed to ensure consistency and quality

- Inspected printed materials for defects and ensured adherence to quality standards

Rotary Lithographic Press Operator

- Produced high-quality printed materials using rotary lithographic presses, achieving consistent color accuracy and registration

- Operated multiple presses simultaneously, optimizing production efficiency and meeting tight deadlines

- Maintained and calibrated presses regularly, ensuring optimal performance and preventing downtime

- Troubleshooted and resolved press issues effectively, minimizing production delays

Accomplishments

- Optimized press operations by implementing a new ink management system, reducing waste by 15% and improving press efficiency by 8%.

- Identified and resolved a critical mechanical issue on the press, preventing costly downtime and ensuring smooth production flow.

- Developed and implemented a preventive maintenance program that extended press life by 20%, reducing repair costs and downtime.

- Collaborated with design and production teams to produce highquality printed materials that met client specifications and exceeded expectations.

- Consistently achieved press production speeds 10% above industry standards, maximizing press utilization and productivity.

Awards

- Received the National Association of Printing Ink Manufacturers (NAPIM) Silver Ink Award for exceptional print quality.

- Recognized as Employee of the Month for consistently exceeding production targets and maintaining exceptional press quality standards.

- Awarded the Print Management Association (PMA) Excellence in Print Award for outstanding lithographic presswork.

- Received the International Association of Printing House Craftsmen (IAPHC) John Jute Scholarship for excellence in the graphic arts industry.

Certificates

- Rotary Lithographic Press Operator Certification

- Print Quality Control Certification

- Occupational Safety and Health Administration (OSHA) Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Rotary Lithographic Press Operator

- Highlight your experience operating multicolor rotary lithographic presses and your ability to maintain consistent print quality.

- Demonstrate your knowledge of color matching and adjustment techniques, as well as your ability to troubleshoot and resolve printing problems.

- Showcase your understanding of web tension control and its importance in maintaining proper paper flow and print quality.

- Emphasize your experience printing on various substrates, including paper, plastic, and metal.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact on the organization.

Essential Experience Highlights for a Strong Rotary Lithographic Press Operator Resume

- Operate multicolor rotary lithographic presses to produce high-quality printed materials.

- Control web tension to ensure proper paper flow and print quality.

- Print on a variety of substrates, including paper, plastic, and metal.

- Match and adjust colors to achieve accurate and consistent print results.

- Troubleshoot and resolve printing problems to minimize downtime and maintain production efficiency.

- Maintain and calibrate dampening systems to ensure optimal ink transfer and print quality.

- Collaborate with other press operators and production staff to ensure smooth and efficient operations.

Frequently Asked Questions (FAQ’s) For Rotary Lithographic Press Operator

What are the primary responsibilities of a Rotary Lithographic Press Operator?

The primary responsibilities of a Rotary Lithographic Press Operator include operating multicolor presses, controlling web tension, printing on various substrates, matching and adjusting colors, troubleshooting and resolving printing problems, and maintaining dampening systems.

What skills are required to be a successful Rotary Lithographic Press Operator?

Successful Rotary Lithographic Press Operators typically possess strong mechanical aptitude, attention to detail, and problem-solving abilities. They also have a thorough understanding of color matching and adjustment techniques, as well as web tension control.

What are the career prospects for a Rotary Lithographic Press Operator?

Rotary Lithographic Press Operators may advance to supervisory roles, such as Pressroom Supervisor or Production Manager. With additional training and experience, they may also move into technical roles, such as Color Technician or Print Quality Specialist.

What is the work environment like for a Rotary Lithographic Press Operator?

Rotary Lithographic Press Operators typically work in a fast-paced, production-oriented environment. They may work independently or as part of a team, and may be required to work overtime or on weekends to meet production deadlines.

What are the salary expectations for a Rotary Lithographic Press Operator?

The salary expectations for a Rotary Lithographic Press Operator vary depending on factors such as experience, location, and company size. According to Indeed, the average salary for a Rotary Lithographic Press Operator in the United States is around $55,000 per year.

What are the challenges of working as a Rotary Lithographic Press Operator?

The challenges of working as a Rotary Lithographic Press Operator include working in a fast-paced environment, meeting production deadlines, and troubleshooting and resolving printing problems. Operators may also be exposed to noise, fumes, and chemicals.

What are the benefits of working as a Rotary Lithographic Press Operator?

The benefits of working as a Rotary Lithographic Press Operator include job security, opportunities for advancement, and the chance to work with cutting-edge printing technology. Operators may also receive benefits such as health insurance, paid time off, and retirement plans.

How can I prepare for a career as a Rotary Lithographic Press Operator?

To prepare for a career as a Rotary Lithographic Press Operator, you can complete a formal training program, such as an associate’s degree in printing technology. You can also gain experience by working in a print shop or taking on internships during college.