Are you a seasoned Rotor Casting Machine Operator seeking a new career path? Discover our professionally built Rotor Casting Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

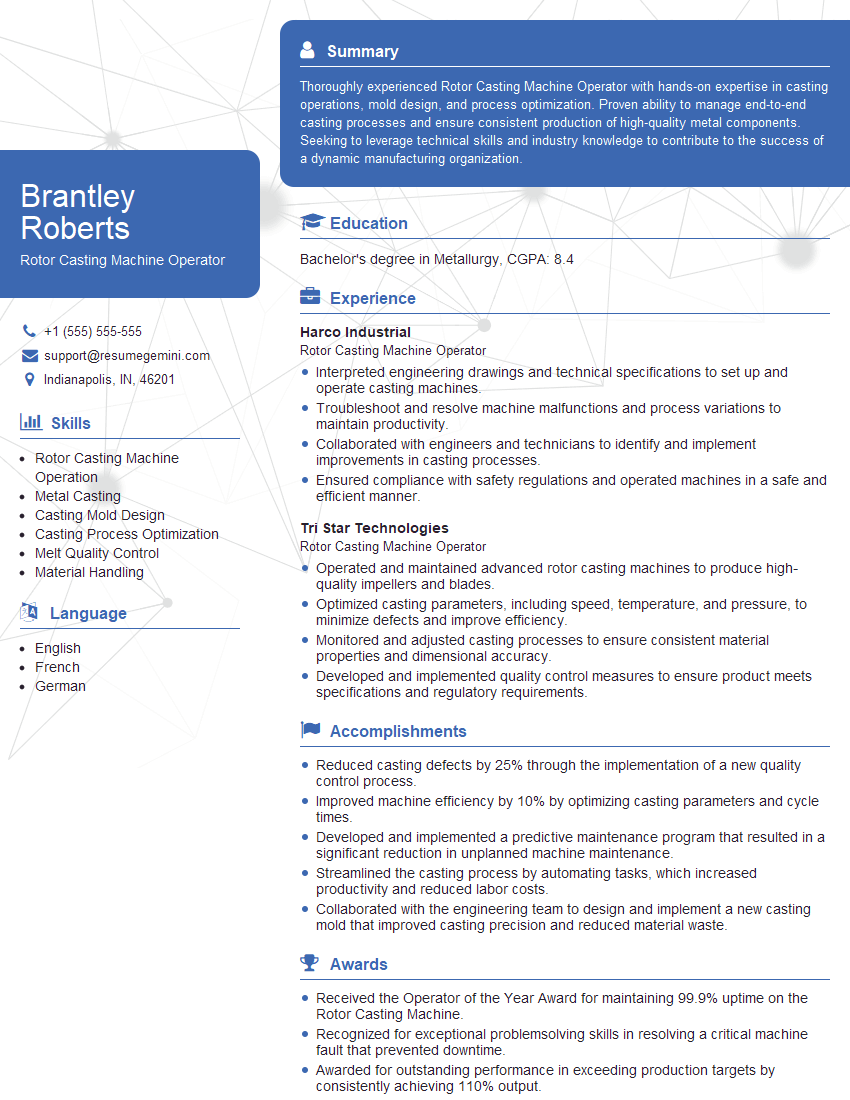

Brantley Roberts

Rotor Casting Machine Operator

Summary

Thoroughly experienced Rotor Casting Machine Operator with hands-on expertise in casting operations, mold design, and process optimization. Proven ability to manage end-to-end casting processes and ensure consistent production of high-quality metal components. Seeking to leverage technical skills and industry knowledge to contribute to the success of a dynamic manufacturing organization.

Education

Bachelor’s degree in Metallurgy

July 2016

Skills

- Rotor Casting Machine Operation

- Metal Casting

- Casting Mold Design

- Casting Process Optimization

- Melt Quality Control

- Material Handling

Work Experience

Rotor Casting Machine Operator

- Interpreted engineering drawings and technical specifications to set up and operate casting machines.

- Troubleshoot and resolve machine malfunctions and process variations to maintain productivity.

- Collaborated with engineers and technicians to identify and implement improvements in casting processes.

- Ensured compliance with safety regulations and operated machines in a safe and efficient manner.

Rotor Casting Machine Operator

- Operated and maintained advanced rotor casting machines to produce high-quality impellers and blades.

- Optimized casting parameters, including speed, temperature, and pressure, to minimize defects and improve efficiency.

- Monitored and adjusted casting processes to ensure consistent material properties and dimensional accuracy.

- Developed and implemented quality control measures to ensure product meets specifications and regulatory requirements.

Accomplishments

- Reduced casting defects by 25% through the implementation of a new quality control process.

- Improved machine efficiency by 10% by optimizing casting parameters and cycle times.

- Developed and implemented a predictive maintenance program that resulted in a significant reduction in unplanned machine maintenance.

- Streamlined the casting process by automating tasks, which increased productivity and reduced labor costs.

- Collaborated with the engineering team to design and implement a new casting mold that improved casting precision and reduced material waste.

Awards

- Received the Operator of the Year Award for maintaining 99.9% uptime on the Rotor Casting Machine.

- Recognized for exceptional problemsolving skills in resolving a critical machine fault that prevented downtime.

- Awarded for outstanding performance in exceeding production targets by consistently achieving 110% output.

- Received a Safety Excellence Award for maintaining a spotless safety record and implementing innovative safety initiatives.

Certificates

- Certified Casting Operator (CCO)

- Certified Quality Inspector (CQI)

- American Foundry Society (AFS) Certification

- National Institute for Metalworking Skills (NIMS) Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Rotor Casting Machine Operator

- Highlight your technical proficiency in rotor casting machine operation and process optimization.

- Showcase your experience in casting mold design and its impact on casting quality and yield.

- Quantify your achievements in reducing defects, improving efficiency, and optimizing production processes.

- Emphasize your commitment to safety and maintaining a well-organized work environment.

Essential Experience Highlights for a Strong Rotor Casting Machine Operator Resume

- Set up and operate rotor casting machines according to specified parameters and procedures.

- Monitor and control molten metal pouring and cooling processes to ensure proper casting quality.

- Design and develop casting molds to meet specific part requirements and maximize yield.

- Implement process optimization techniques to improve casting yield, reduce defects, and increase efficiency.

- Conduct melt quality checks and ensure compliance with established standards.

- Maintain a clean and organized work area, adhering to safety protocols and industry best practices.

Frequently Asked Questions (FAQ’s) For Rotor Casting Machine Operator

What are the essential skills required for a Rotor Casting Machine Operator?

A successful Rotor Casting Machine Operator possesses expertise in machine operation, metal casting techniques, casting mold design, and process optimization. They must also have a strong understanding of melt quality control and material handling.

What are the career prospects for a Rotor Casting Machine Operator?

Experienced Rotor Casting Machine Operators have opportunities for career advancement within the manufacturing industry. With additional training and experience, they can progress to supervisory roles, such as Casting Supervisor or Production Manager.

What is the work environment like for a Rotor Casting Machine Operator?

Rotor Casting Machine Operators typically work in industrial settings, where they are exposed to noise, heat, and potential hazards associated with molten metal and machinery. They must adhere to safety protocols and wear appropriate protective gear.

How can I improve my resume for a Rotor Casting Machine Operator position?

To enhance your resume, focus on highlighting your technical skills, previous experience, and any certifications or training related to rotor casting. Quantify your accomplishments and use specific examples to demonstrate your impact on production efficiency and quality.

What are the key factors to consider when designing casting molds?

When designing casting molds, it is crucial to consider the geometry of the part, the type of metal being cast, the cooling rate, and the desired surface finish. The mold design should ensure proper metal flow, solidification, and ejection of the cast part.

How can I optimize casting processes to improve yield and quality?

To optimize casting processes, focus on controlling pouring temperature, cooling rates, and mold design. Implementing techniques such as directional solidification, vacuum casting, and pressure casting can also enhance yield and reduce defects.

What are the safety precautions that should be taken when operating a Rotor Casting Machine?

When operating a Rotor Casting Machine, it is essential to wear appropriate protective gear, including heat-resistant clothing, gloves, and eye protection. Regular maintenance and adherence to safety protocols are crucial to minimize risks associated with molten metal, machinery, and electrical hazards.

How can I stay updated on the latest advancements in rotor casting technology?

To stay abreast of the latest advancements, attend industry conferences, workshops, and training programs. Read technical journals, white papers, and articles related to rotor casting. Network with professionals in the field and engage with industry experts on online forums and social media.