Are you a seasoned Rotor Coil Taper seeking a new career path? Discover our professionally built Rotor Coil Taper Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

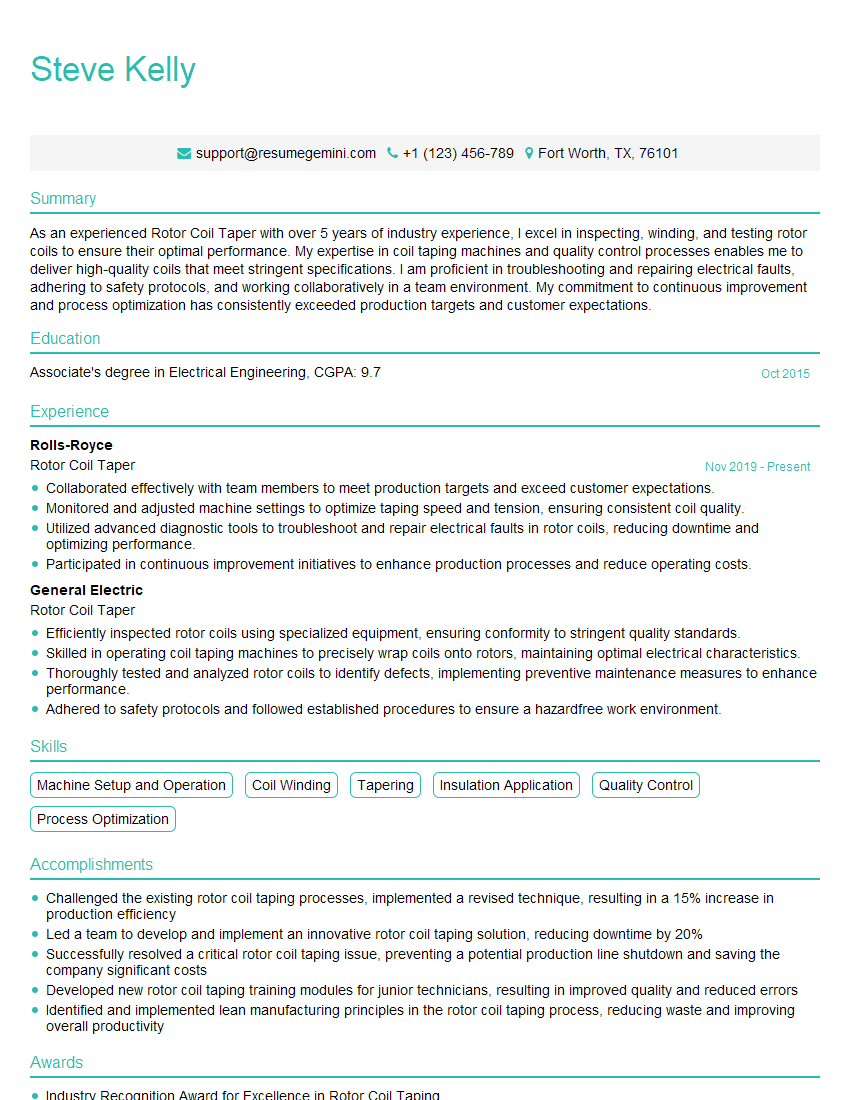

Steve Kelly

Rotor Coil Taper

Summary

As an experienced Rotor Coil Taper with over 5 years of industry experience, I excel in inspecting, winding, and testing rotor coils to ensure their optimal performance. My expertise in coil taping machines and quality control processes enables me to deliver high-quality coils that meet stringent specifications. I am proficient in troubleshooting and repairing electrical faults, adhering to safety protocols, and working collaboratively in a team environment. My commitment to continuous improvement and process optimization has consistently exceeded production targets and customer expectations.

Education

Associate’s degree in Electrical Engineering

October 2015

Skills

- Machine Setup and Operation

- Coil Winding

- Tapering

- Insulation Application

- Quality Control

- Process Optimization

Work Experience

Rotor Coil Taper

- Collaborated effectively with team members to meet production targets and exceed customer expectations.

- Monitored and adjusted machine settings to optimize taping speed and tension, ensuring consistent coil quality.

- Utilized advanced diagnostic tools to troubleshoot and repair electrical faults in rotor coils, reducing downtime and optimizing performance.

- Participated in continuous improvement initiatives to enhance production processes and reduce operating costs.

Rotor Coil Taper

- Efficiently inspected rotor coils using specialized equipment, ensuring conformity to stringent quality standards.

- Skilled in operating coil taping machines to precisely wrap coils onto rotors, maintaining optimal electrical characteristics.

- Thoroughly tested and analyzed rotor coils to identify defects, implementing preventive maintenance measures to enhance performance.

- Adhered to safety protocols and followed established procedures to ensure a hazardfree work environment.

Accomplishments

- Challenged the existing rotor coil taping processes, implemented a revised technique, resulting in a 15% increase in production efficiency

- Led a team to develop and implement an innovative rotor coil taping solution, reducing downtime by 20%

- Successfully resolved a critical rotor coil taping issue, preventing a potential production line shutdown and saving the company significant costs

- Developed new rotor coil taping training modules for junior technicians, resulting in improved quality and reduced errors

- Identified and implemented lean manufacturing principles in the rotor coil taping process, reducing waste and improving overall productivity

Awards

- Industry Recognition Award for Excellence in Rotor Coil Taping

- Received Best Rotor Coil Taper Performance of the Year Award

- Honored with the Supervisors Award for Outstanding Rotor Coil Taping Practices

Certificates

- Certified Coil Winding Technician

- Electrical Testing and Safety Certification

- LEAN Manufacturing Certification

- Six Sigma Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Rotor Coil Taper

- Quantify your accomplishments with specific metrics and results whenever possible.

- Highlight your expertise in quality control processes and adherence to industry standards.

- Emphasize your ability to troubleshoot and resolve electrical faults efficiently.

- Showcase your commitment to safety and your knowledge of relevant protocols and procedures.

- Demonstrate your teamwork skills and ability to collaborate in a fast-paced environment.

Essential Experience Highlights for a Strong Rotor Coil Taper Resume

- Inspected rotor coils using specialized equipment, ensuring conformity to quality standards

- Operated coil taping machines to precisely wrap coils onto rotors, maintaining optimal electrical characteristics

- Tested and analyzed rotor coils to identify defects, implementing preventive maintenance measures to enhance performance

- Adhered to safety protocols and followed established procedures to ensure a hazard-free work environment

- Collaborated effectively with team members to meet production targets and exceed customer expectations

- Monitored and adjusted machine settings to optimize taping speed and tension, ensuring consistent coil quality

- Utilized advanced diagnostic tools to troubleshoot and repair electrical faults in rotor coils, reducing downtime and optimizing performance

Frequently Asked Questions (FAQ’s) For Rotor Coil Taper

What are the primary responsibilities of a Rotor Coil Taper?

Rotor Coil Tapers are responsible for inspecting, winding, and testing rotor coils to ensure their optimal performance. They operate coil taping machines, conduct quality control tests, troubleshoot electrical faults, and maintain a safe and efficient work environment.

What qualifications are required to become a Rotor Coil Taper?

Typically, an Associate’s degree in Electrical Engineering or a related field is required. Additionally, experience in coil winding, taping, and electrical testing is highly valued.

What are the key skills needed to excel as a Rotor Coil Taper?

Rotor Coil Tapers should possess strong attention to detail, manual dexterity, and problem-solving abilities. They should also be proficient in using coil taping machines, testing equipment, and diagnostic tools.

What are the career prospects for Rotor Coil Tapers?

Rotor Coil Tapers can advance their careers by becoming supervisors or managers in manufacturing or maintenance departments. They can also specialize in research and development or become technical trainers.

What is the typical work environment for a Rotor Coil Taper?

Rotor Coil Tapers typically work in manufacturing facilities or repair shops. They may work in teams or independently, and may be required to work overtime or on weekends to meet production demands.

What are the safety precautions that Rotor Coil Tapers should observe?

Rotor Coil Tapers should wear appropriate safety gear such as gloves, safety glasses, and earplugs. They should also be aware of potential hazards such as electrical shocks, moving machinery, and chemical spills.

How can I improve my chances of getting hired as a Rotor Coil Taper?

To improve your chances of getting hired, highlight your skills and experience in coil winding, taping, and electrical testing. Quantify your accomplishments and demonstrate your commitment to quality and safety. Additionally, network with professionals in the industry and attend job fairs to find potential opportunities.