Are you a seasoned Roughing Mill Operator seeking a new career path? Discover our professionally built Roughing Mill Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

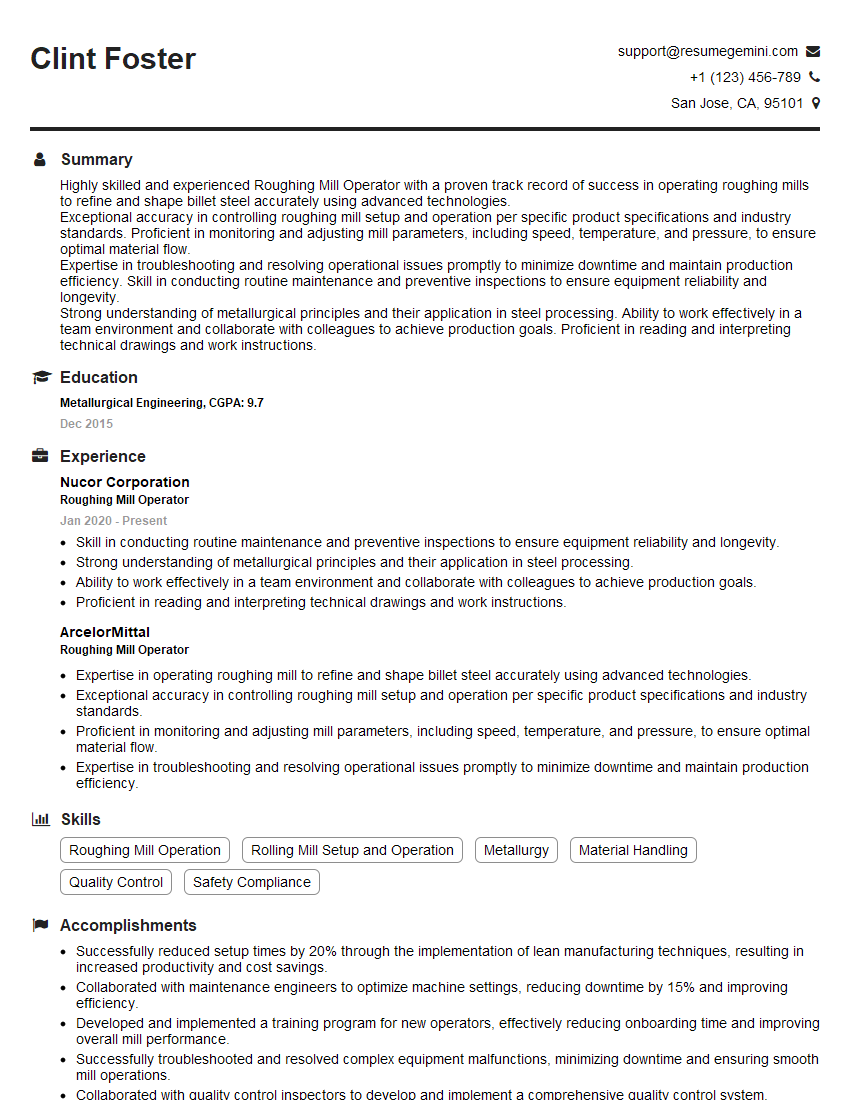

Clint Foster

Roughing Mill Operator

Summary

Highly skilled and experienced Roughing Mill Operator with a proven track record of success in operating roughing mills to refine and shape billet steel accurately using advanced technologies.

Exceptional accuracy in controlling roughing mill setup and operation per specific product specifications and industry standards. Proficient in monitoring and adjusting mill parameters, including speed, temperature, and pressure, to ensure optimal material flow.

Expertise in troubleshooting and resolving operational issues promptly to minimize downtime and maintain production efficiency. Skill in conducting routine maintenance and preventive inspections to ensure equipment reliability and longevity.

Strong understanding of metallurgical principles and their application in steel processing. Ability to work effectively in a team environment and collaborate with colleagues to achieve production goals. Proficient in reading and interpreting technical drawings and work instructions.

Education

Metallurgical Engineering

December 2015

Skills

- Roughing Mill Operation

- Rolling Mill Setup and Operation

- Metallurgy

- Material Handling

- Quality Control

- Safety Compliance

Work Experience

Roughing Mill Operator

- Skill in conducting routine maintenance and preventive inspections to ensure equipment reliability and longevity.

- Strong understanding of metallurgical principles and their application in steel processing.

- Ability to work effectively in a team environment and collaborate with colleagues to achieve production goals.

- Proficient in reading and interpreting technical drawings and work instructions.

Roughing Mill Operator

- Expertise in operating roughing mill to refine and shape billet steel accurately using advanced technologies.

- Exceptional accuracy in controlling roughing mill setup and operation per specific product specifications and industry standards.

- Proficient in monitoring and adjusting mill parameters, including speed, temperature, and pressure, to ensure optimal material flow.

- Expertise in troubleshooting and resolving operational issues promptly to minimize downtime and maintain production efficiency.

Accomplishments

- Successfully reduced setup times by 20% through the implementation of lean manufacturing techniques, resulting in increased productivity and cost savings.

- Collaborated with maintenance engineers to optimize machine settings, reducing downtime by 15% and improving efficiency.

- Developed and implemented a training program for new operators, effectively reducing onboarding time and improving overall mill performance.

- Successfully troubleshooted and resolved complex equipment malfunctions, minimizing downtime and ensuring smooth mill operations.

- Collaborated with quality control inspectors to develop and implement a comprehensive quality control system, improving product accuracy and reducing customer complaints.

Awards

- Received the Employee of the Year award for exceptional performance and contributions as a Roughing Mill Operator.

- Recognized with the Safety Excellence Award for maintaining an impeccable safety record and actively contributing to the safety culture of the mill.

- Consistently exceeded production targets by over 10%, earning a reputation for reliability and highquality output.

- Received a Teamwork Award for actively participating in crossfunctional initiatives that improved mill operations.

Certificates

- Certified Rolling Mill Operator

- OHSA Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Roughing Mill Operator

- Quantify your accomplishments and provide specific examples of your success in operating roughing mills.

- Highlight your expertise in metallurgy and your understanding of metallurgical principles and their application in steel processing.

- Demonstrate your ability to work independently and as part of a team, and your commitment to safety and quality.

- Proofread your resume carefully for any errors in grammar, spelling, or punctuation

- Tailor your resume to each job you apply for, highlighting the skills and experience that are most relevant to the position.

Essential Experience Highlights for a Strong Roughing Mill Operator Resume

- Operate roughing mills to refine and shape billet steel accurately using advanced technologies.

- Control roughing mill setup and operation per specific product specifications and industry standards.

- Monitor and adjust mill parameters, including speed, temperature, and pressure, to ensure optimal material flow.

- Troubleshoot and resolve operational issues promptly to minimize downtime and maintain production efficiency.

- Conduct routine maintenance and preventive inspections to ensure equipment reliability and longevity.

- Work effectively in a team environment and collaborate with colleagues to achieve production goals.

- Read and interpret technical drawings and work instructions.

Frequently Asked Questions (FAQ’s) For Roughing Mill Operator

What is the role of a Roughing Mill Operator?

A Roughing Mill Operator is responsible for operating roughing mills to refine and shape billet steel accurately using advanced technologies. They control roughing mill setup and operation per specific product specifications and industry standards.

What are the key skills required to be a successful Roughing Mill Operator?

The key skills required to be a successful Roughing Mill Operator include expertise in operating roughing mills, controlling mill setup and operation, monitoring and adjusting mill parameters, troubleshooting and resolving operational issues, conducting routine maintenance and preventive inspections, and working effectively in a team environment.

What are the career prospects for Roughing Mill Operators?

Roughing Mill Operators can advance to supervisory roles, such as Roughing Mill Supervisor or Rolling Mill Manager. They may also move into related fields, such as Metallurgical Engineering or Quality Control.

What is the work environment of a Roughing Mill Operator like?

Roughing Mill Operators typically work in a manufacturing environment, such as a steel mill or rolling mill. They work in close proximity to heavy machinery and equipment, and may be exposed to noise, heat, and dust.

What are the safety precautions that Roughing Mill Operators must take?

Roughing Mill Operators must follow all safety protocols and procedures, including wearing appropriate personal protective equipment (PPE), such as safety glasses, gloves, and earplugs. They must also be aware of the potential hazards associated with operating heavy machinery and equipment.

What is the salary range for Roughing Mill Operators?

The salary range for Roughing Mill Operators can vary depending on their experience, location, and employer. According to Salary.com, the average salary for Roughing Mill Operators in the United States is around $60,000 per year.

What are the benefits of working as a Roughing Mill Operator?

The benefits of working as a Roughing Mill Operator can include a competitive salary, comprehensive benefits package, opportunities for advancement, and job security.