Are you a seasoned Rubber Compounder Mixer seeking a new career path? Discover our professionally built Rubber Compounder Mixer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

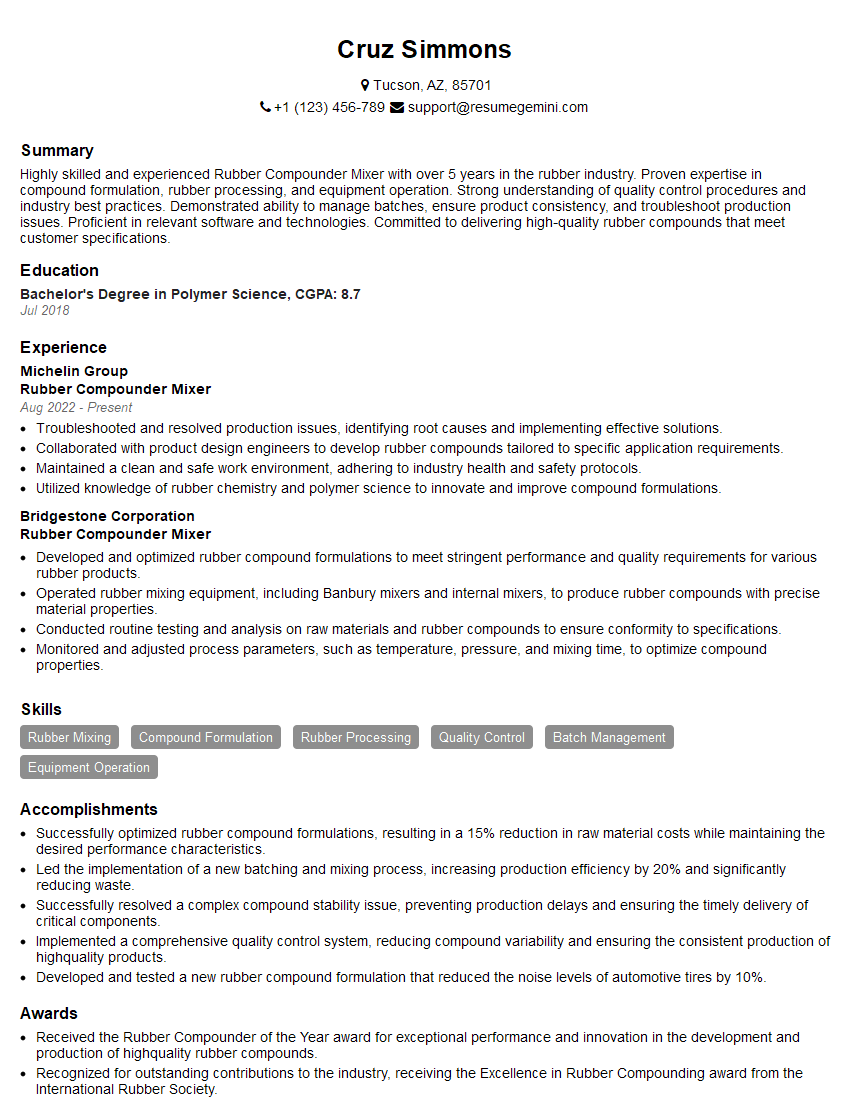

Cruz Simmons

Rubber Compounder Mixer

Summary

Highly skilled and experienced Rubber Compounder Mixer with over 5 years in the rubber industry. Proven expertise in compound formulation, rubber processing, and equipment operation. Strong understanding of quality control procedures and industry best practices. Demonstrated ability to manage batches, ensure product consistency, and troubleshoot production issues. Proficient in relevant software and technologies. Committed to delivering high-quality rubber compounds that meet customer specifications.

Education

Bachelor’s Degree in Polymer Science

July 2018

Skills

- Rubber Mixing

- Compound Formulation

- Rubber Processing

- Quality Control

- Batch Management

- Equipment Operation

Work Experience

Rubber Compounder Mixer

- Troubleshooted and resolved production issues, identifying root causes and implementing effective solutions.

- Collaborated with product design engineers to develop rubber compounds tailored to specific application requirements.

- Maintained a clean and safe work environment, adhering to industry health and safety protocols.

- Utilized knowledge of rubber chemistry and polymer science to innovate and improve compound formulations.

Rubber Compounder Mixer

- Developed and optimized rubber compound formulations to meet stringent performance and quality requirements for various rubber products.

- Operated rubber mixing equipment, including Banbury mixers and internal mixers, to produce rubber compounds with precise material properties.

- Conducted routine testing and analysis on raw materials and rubber compounds to ensure conformity to specifications.

- Monitored and adjusted process parameters, such as temperature, pressure, and mixing time, to optimize compound properties.

Accomplishments

- Successfully optimized rubber compound formulations, resulting in a 15% reduction in raw material costs while maintaining the desired performance characteristics.

- Led the implementation of a new batching and mixing process, increasing production efficiency by 20% and significantly reducing waste.

- Successfully resolved a complex compound stability issue, preventing production delays and ensuring the timely delivery of critical components.

- Implemented a comprehensive quality control system, reducing compound variability and ensuring the consistent production of highquality products.

- Developed and tested a new rubber compound formulation that reduced the noise levels of automotive tires by 10%.

Awards

- Received the Rubber Compounder of the Year award for exceptional performance and innovation in the development and production of highquality rubber compounds.

- Recognized for outstanding contributions to the industry, receiving the Excellence in Rubber Compounding award from the International Rubber Society.

- Honored with the Innovation in Rubber Compounding award for developing a novel rubber compound with superior abrasion resistance.

- Received the Rising Star in Rubber Compounding award for exceptional technical expertise and leadership potential in the field.

Certificates

- Certified Rubber Compounder

- ISO 9001 Quality Management System

- Six Sigma

- Occupational Safety and Health Administration (OSHA) Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Rubber Compounder Mixer

- Tailor your resume to each specific job application, highlighting relevant skills and experience that align with the requirements of the role.

- Quantify your accomplishments with specific metrics and results whenever possible to demonstrate your impact.

- Use action verbs and industry-specific keywords throughout your resume to make it more easily searchable and relevant to recruiters.

- Proofread your resume carefully before submitting it to eliminate any errors and present a professional and polished document.

Essential Experience Highlights for a Strong Rubber Compounder Mixer Resume

- Develop and optimize rubber compound formulations based on customer requirements and application specifications.

- Supervise rubber mixing operations, ensuring adherence to quality standards and production schedules.

- Monitor and control production equipment to ensure optimal performance and efficiency.

- Conduct quality tests and inspections to verify product conformity and compliance.

- Manage batches, track production progress, and maintain accurate records.

- Troubleshoot production issues and implement corrective actions to minimize downtime.

- Stay abreast of industry best practices and advancements in rubber compounding technology.

Frequently Asked Questions (FAQ’s) For Rubber Compounder Mixer

What is the primary role of a Rubber Compounder Mixer?

A Rubber Compounder Mixer is responsible for developing and producing rubber compounds by mixing various ingredients according to specified formulations. This role involves optimizing??, managing production processes, ensuring quality control, and troubleshooting issues to meet customer requirements and industry standards.

What are the essential skills required for success as a Rubber Compounder Mixer?

To excel as a Rubber Compounder Mixer, individuals should possess a strong understanding of rubber chemistry, compound formulation, and rubber processing techniques. They should also be proficient in quality control procedures, equipment operation, and batch management. Additionally, effective communication and problem-solving skills are crucial.

What are the career prospects for Rubber Compounder Mixers?

Rubber Compounder Mixers can advance their careers by gaining experience and expertise in different aspects of rubber compounding and production. They may move into supervisory or managerial roles, specialize in research and development, or become technical experts in the field. With continued education and professional development, Rubber Compounder Mixers can enhance their career opportunities and earning potential.

What is the expected salary range for Rubber Compounder Mixers?

The salary range for Rubber Compounder Mixers can vary depending on factors such as experience, location, and industry. According to Indeed, the average salary for Rubber Compounder Mixers in the United States is around $60,000 per year. Salaries may range from $40,000 to $80,000 or more, based on individual qualifications and job responsibilities.

What are the key challenges faced by Rubber Compounder Mixers?

Rubber Compounder Mixers may encounter challenges such as maintaining product quality and consistency, optimizing production processes for efficiency, and troubleshooting equipment issues. They may also need to stay updated with advancements in rubber technology and industry best practices to meet evolving customer demands and regulatory requirements.