Are you a seasoned Rubber Splicer seeking a new career path? Discover our professionally built Rubber Splicer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

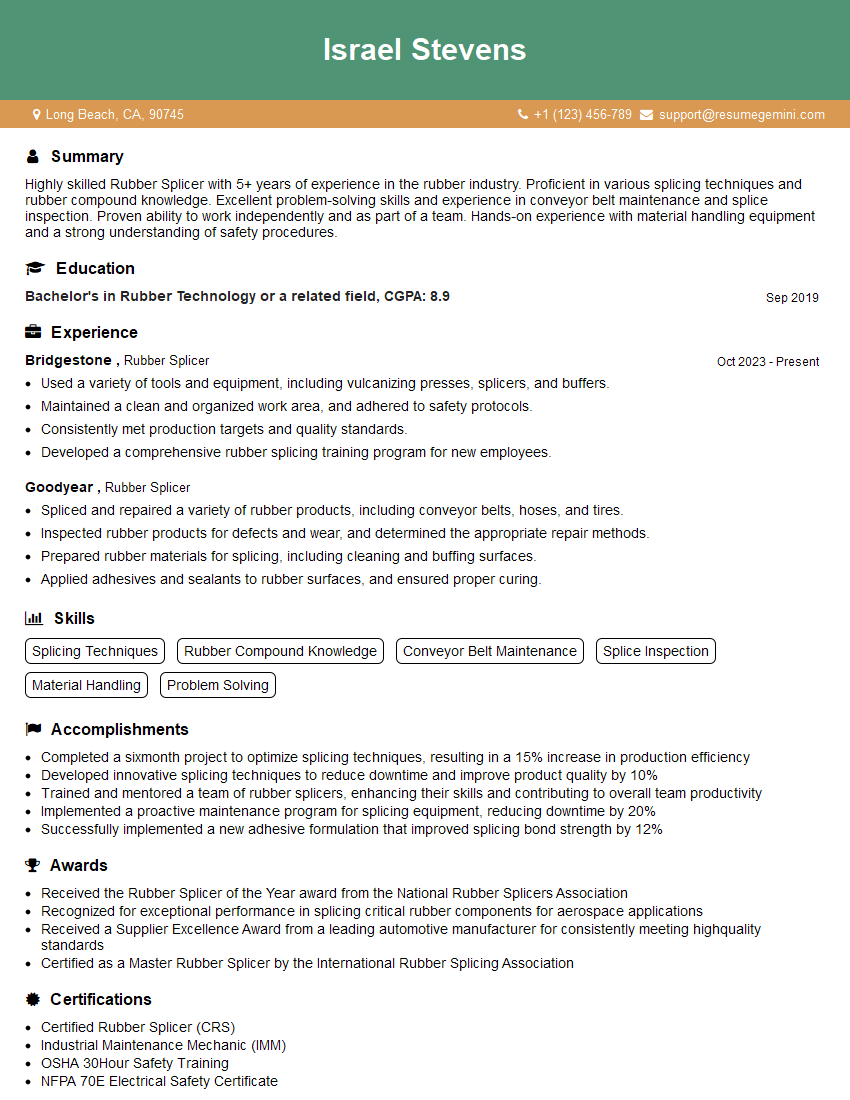

Israel Stevens

Rubber Splicer

Summary

Highly skilled Rubber Splicer with 5+ years of experience in the rubber industry. Proficient in various splicing techniques and rubber compound knowledge. Excellent problem-solving skills and experience in conveyor belt maintenance and splice inspection. Proven ability to work independently and as part of a team. Hands-on experience with material handling equipment and a strong understanding of safety procedures.

Education

Bachelor’s in Rubber Technology or a related field

September 2019

Skills

- Splicing Techniques

- Rubber Compound Knowledge

- Conveyor Belt Maintenance

- Splice Inspection

- Material Handling

- Problem Solving

Work Experience

Rubber Splicer

- Used a variety of tools and equipment, including vulcanizing presses, splicers, and buffers.

- Maintained a clean and organized work area, and adhered to safety protocols.

- Consistently met production targets and quality standards.

- Developed a comprehensive rubber splicing training program for new employees.

Rubber Splicer

- Spliced and repaired a variety of rubber products, including conveyor belts, hoses, and tires.

- Inspected rubber products for defects and wear, and determined the appropriate repair methods.

- Prepared rubber materials for splicing, including cleaning and buffing surfaces.

- Applied adhesives and sealants to rubber surfaces, and ensured proper curing.

Accomplishments

- Completed a sixmonth project to optimize splicing techniques, resulting in a 15% increase in production efficiency

- Developed innovative splicing techniques to reduce downtime and improve product quality by 10%

- Trained and mentored a team of rubber splicers, enhancing their skills and contributing to overall team productivity

- Implemented a proactive maintenance program for splicing equipment, reducing downtime by 20%

- Successfully implemented a new adhesive formulation that improved splicing bond strength by 12%

Awards

- Received the Rubber Splicer of the Year award from the National Rubber Splicers Association

- Recognized for exceptional performance in splicing critical rubber components for aerospace applications

- Received a Supplier Excellence Award from a leading automotive manufacturer for consistently meeting highquality standards

- Certified as a Master Rubber Splicer by the International Rubber Splicing Association

Certificates

- Certified Rubber Splicer (CRS)

- Industrial Maintenance Mechanic (IMM)

- OSHA 30Hour Safety Training

- NFPA 70E Electrical Safety Certificate

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Rubber Splicer

- Highlight your proficiency in specific splicing techniques, such as hot splicing, cold splicing, and vulcanizing.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate the impact of your work.

- Showcase your understanding of rubber compound properties and how they affect splicing outcomes.

- Emphasize your ability to identify and troubleshoot splicing issues effectively, minimizing downtime and improving productivity.

Essential Experience Highlights for a Strong Rubber Splicer Resume

- Splice and repair conveyor belts using various techniques, ensuring optimal performance and minimizing downtime.

- Inspect splices for defects and ensure they meet quality standards.

- Troubleshoot and resolve splicing issues promptly to avoid production delays.

- Maintain and calibrate splicing equipment to ensure accuracy and efficiency.

- Collaborate with maintenance and engineering teams to identify and implement improvements in splicing processes.

- Train and supervise junior splicers to ensure proper techniques and safety protocols are followed.

- Monitor material inventory and order supplies to avoid shortages.

Frequently Asked Questions (FAQ’s) For Rubber Splicer

What are the key skills required to be a Rubber Splicer?

Strong splicing techniques, knowledge of rubber compounds, conveyor belt maintenance, splice inspection, material handling, problem-solving, and attention to detail are essential for Rubber Splicers.

What industries employ Rubber Splicers?

Rubber Splicers are primarily employed in manufacturing industries that utilize conveyor belts, such as mining, automotive, food processing, and construction.

Is experience necessary to become a Rubber Splicer?

While formal training programs exist, most Rubber Splicers gain their skills through on-the-job training and apprenticeship programs.

What are the career advancement opportunities for Rubber Splicers?

With experience and additional training, Rubber Splicers can advance to supervisory roles, such as Lead Splicer or Splicing Foreman, or specialize in specific areas, such as splicing conveyor belts for heavy machinery or hazardous materials.

What safety precautions should Rubber Splicers observe?

Rubber Splicers must adhere to strict safety protocols, including wearing appropriate protective gear, following proper handling procedures for rubber compounds, and maintaining a clean and organized work area.

What is the job outlook for Rubber Splicers?

The job outlook for Rubber Splicers is expected to be stable, with demand driven by the ongoing need for conveyor belt maintenance and repair in various industries.

Can Rubber Splicers work independently?

While Rubber Splicers often work as part of a team, they may also be required to perform tasks independently, such as inspecting and repairing conveyor belts in remote locations.

What certifications are beneficial for Rubber Splicers?

Obtaining certifications from organizations like the International Rubber Industry Association (IRIA) or the National Institute for Certification in Engineering Technologies (NICET) can enhance a Rubber Splicer’s credibility and expertise.