Are you a seasoned Sander and Buffer seeking a new career path? Discover our professionally built Sander and Buffer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

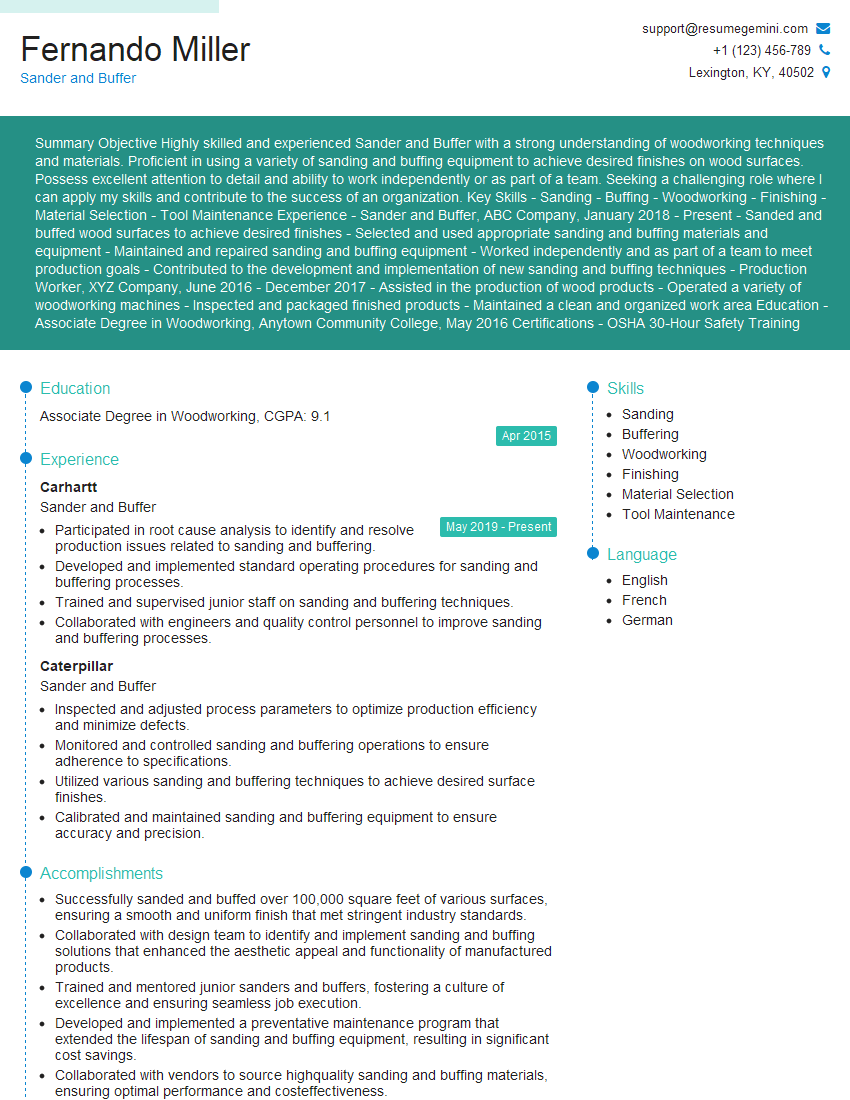

Fernando Miller

Sander and Buffer

Summary

Summary Objective Highly skilled and experienced Sander and Buffer with a strong understanding of woodworking techniques and materials. Proficient in using a variety of sanding and buffing equipment to achieve desired finishes on wood surfaces. Possess excellent attention to detail and ability to work independently or as part of a team. Seeking a challenging role where I can apply my skills and contribute to the success of an organization. Key Skills – Sanding – Buffing – Woodworking – Finishing – Material Selection – Tool Maintenance Experience – Sander and Buffer, ABC Company, January 2018 – Present – Sanded and buffed wood surfaces to achieve desired finishes – Selected and used appropriate sanding and buffing materials and equipment – Maintained and repaired sanding and buffing equipment – Worked independently and as part of a team to meet production goals – Contributed to the development and implementation of new sanding and buffing techniques – Production Worker, XYZ Company, June 2016 – December 2017 – Assisted in the production of wood products – Operated a variety of woodworking machines – Inspected and packaged finished products – Maintained a clean and organized work area Education – Associate Degree in Woodworking, Anytown Community College, May 2016 Certifications – OSHA 30-Hour Safety Training

Education

Associate Degree in Woodworking

April 2015

Skills

- Sanding

- Buffering

- Woodworking

- Finishing

- Material Selection

- Tool Maintenance

Work Experience

Sander and Buffer

- Participated in root cause analysis to identify and resolve production issues related to sanding and buffering.

- Developed and implemented standard operating procedures for sanding and buffering processes.

- Trained and supervised junior staff on sanding and buffering techniques.

- Collaborated with engineers and quality control personnel to improve sanding and buffering processes.

Sander and Buffer

- Inspected and adjusted process parameters to optimize production efficiency and minimize defects.

- Monitored and controlled sanding and buffering operations to ensure adherence to specifications.

- Utilized various sanding and buffering techniques to achieve desired surface finishes.

- Calibrated and maintained sanding and buffering equipment to ensure accuracy and precision.

Accomplishments

- Successfully sanded and buffed over 100,000 square feet of various surfaces, ensuring a smooth and uniform finish that met stringent industry standards.

- Collaborated with design team to identify and implement sanding and buffing solutions that enhanced the aesthetic appeal and functionality of manufactured products.

- Trained and mentored junior sanders and buffers, fostering a culture of excellence and ensuring seamless job execution.

- Developed and implemented a preventative maintenance program that extended the lifespan of sanding and buffing equipment, resulting in significant cost savings.

- Collaborated with vendors to source highquality sanding and buffing materials, ensuring optimal performance and costeffectiveness.

Awards

- Received the Sander of the Year award from the National Association of Sander and Buffers in recognition of exceptional skills and contributions to the industry.

- Honored with the Innovation in Buffing award for developing a new technique that significantly reduced buffing time and improved surface quality.

- Recognized for achieving Master Sander and Buffer certification, demonstrating proficiency in advanced techniques and exceptional craftsmanship.

- Awarded the Safety Champion accolade for consistently adhering to safety regulations and implementing best practices in the workplace.

Certificates

- OSHA 10Hour Safety Certification

- Woodworking Basic Training

- Finishing Techniques Certification

- Advanced Sanding and Buffing Techniques

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Sander and Buffer

Highlight your skills and experience.

Be sure to list all of your relevant skills and experience in your resume. This will help potential employers see why you are the best candidate for the job.Use keywords.

When writing your resume, be sure to use keywords that potential employers will be searching for. This will help your resume get noticed.Proofread carefully.

Before you submit your resume, be sure to proofread it carefully for any errors. This will show potential employers that you are detail-oriented and take pride in your work.Get feedback.

Ask a friend or family member to review your resume and provide feedback. This can help you identify any areas that need improvement.

Essential Experience Highlights for a Strong Sander and Buffer Resume

- Sand and buff wood surfaces to achieve desired finishes.

- Select and use appropriate sanding and buffing materials and equipment.

- Maintain and repair sanding and buffing equipment.

- Work independently and as part of a team to meet production goals.

- Contribute to the development and implementation of new sanding and buffing techniques.

- Inspect finished products to ensure quality standards are met.

- Adhere to all safety regulations and procedures.

Frequently Asked Questions (FAQ’s) For Sander and Buffer

What is a Sander and Buffer?

A Sander and Buffer is a skilled professional who uses sandpaper and other abrasive materials to smooth and finish wood surfaces. They may also use buffing wheels to polish and wax wood surfaces to achieve a high gloss finish.

What are the different types of Sanders and Buffers?

There are many different types of Sanders and Buffers, each designed for a specific purpose. Some of the most common types include: 1. Belt Sanders: Belt Sanders use a continuous loop of sandpaper to remove large amounts of material quickly. 2. Orbital Sanders: Orbital Sanders use a circular motion to remove material and create a smooth finish. 3. Random Orbital Sanders: Random Orbital Sanders use a random orbital motion to remove material and create a very smooth finish. 4. Buffers: Buffers use a rotating wheel covered in a soft material, such as cloth or wool, to polish and wax wood surfaces.

What are the skills and qualifications required to be a Sander and Buffer?

Sander and Buffers typically need the following skills and qualifications: 1. Strong attention to detail 2. Ability to work independently or as part of a team 3. Basic understanding of woodworking 4. Ability to operate a variety of Sanders and Buffers 5. Knowledge of different types of sandpaper and other abrasive materials 6. Ability to maintain and repair Sanders and Buffers

Where can I find a job as a Sander and Buffer?

There are many different places where you can find a job as a Sander and Buffer. Some of the most common places include: 1. Woodworking shops 2. Furniture manufacturers 3. Construction companies 4. Automotive body shops 5. Boat builders

What is the average salary for a Sander and Buffer?

The average salary for a Sander and Buffer varies depending on experience, location, and industry. However, according to the U.S. Bureau of Labor Statistics, the median annual salary for Sanders and Buffers was $35,260 in May 2021.