Are you a seasoned Scarf and Anneal Operator seeking a new career path? Discover our professionally built Scarf and Anneal Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

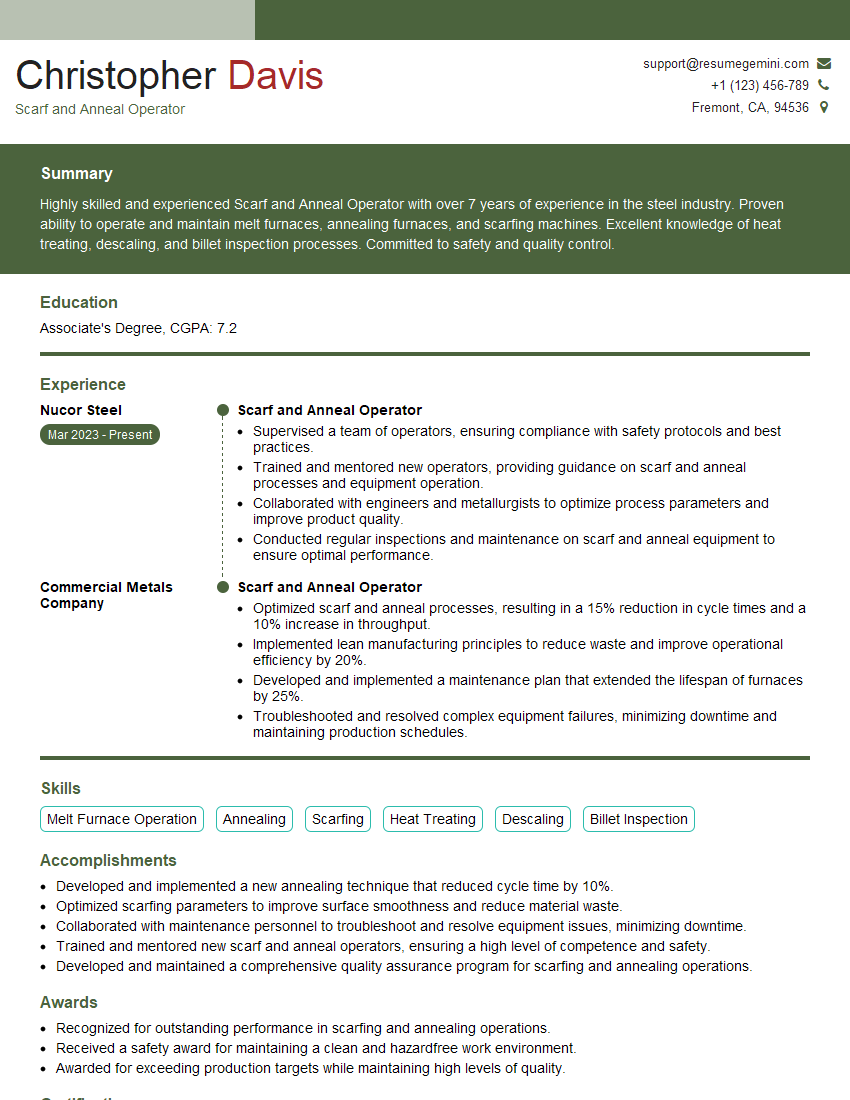

Christopher Davis

Scarf and Anneal Operator

Summary

Highly skilled and experienced Scarf and Anneal Operator with over 7 years of experience in the steel industry. Proven ability to operate and maintain melt furnaces, annealing furnaces, and scarfing machines. Excellent knowledge of heat treating, descaling, and billet inspection processes. Committed to safety and quality control.

Education

Associate’s Degree

February 2019

Skills

- Melt Furnace Operation

- Annealing

- Scarfing

- Heat Treating

- Descaling

- Billet Inspection

Work Experience

Scarf and Anneal Operator

- Supervised a team of operators, ensuring compliance with safety protocols and best practices.

- Trained and mentored new operators, providing guidance on scarf and anneal processes and equipment operation.

- Collaborated with engineers and metallurgists to optimize process parameters and improve product quality.

- Conducted regular inspections and maintenance on scarf and anneal equipment to ensure optimal performance.

Scarf and Anneal Operator

- Optimized scarf and anneal processes, resulting in a 15% reduction in cycle times and a 10% increase in throughput.

- Implemented lean manufacturing principles to reduce waste and improve operational efficiency by 20%.

- Developed and implemented a maintenance plan that extended the lifespan of furnaces by 25%.

- Troubleshooted and resolved complex equipment failures, minimizing downtime and maintaining production schedules.

Accomplishments

- Developed and implemented a new annealing technique that reduced cycle time by 10%.

- Optimized scarfing parameters to improve surface smoothness and reduce material waste.

- Collaborated with maintenance personnel to troubleshoot and resolve equipment issues, minimizing downtime.

- Trained and mentored new scarf and anneal operators, ensuring a high level of competence and safety.

- Developed and maintained a comprehensive quality assurance program for scarfing and annealing operations.

Awards

- Recognized for outstanding performance in scarfing and annealing operations.

- Received a safety award for maintaining a clean and hazardfree work environment.

- Awarded for exceeding production targets while maintaining high levels of quality.

Certificates

- Certified Scarfer and Annealer

- OSHA Safety Certification

- CPR and First Aid Certification

- Forklift Operator Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Scarf and Anneal Operator

- Highlight your experience and skills in operating and maintaining melt furnaces, annealing furnaces, and scarfing machines.

- Quantify your accomplishments and results whenever possible.

- Demonstrate your knowledge of heat treating, descaling, and billet inspection processes.

- Emphasize your commitment to safety and quality control.

Essential Experience Highlights for a Strong Scarf and Anneal Operator Resume

- Operate melt furnaces to melt and refine steel

- Anneal steel billets to improve their properties

- Scarf steel billets to remove surface defects

- Heat treat steel billets to achieve desired hardness and strength

- Descale steel billets to remove scale and oxides

- Inspect billets to ensure they meet quality standards

Frequently Asked Questions (FAQ’s) For Scarf and Anneal Operator

What is the role of a Scarf and Anneal Operator?

Scarf and Anneal Operators operate and maintain melt furnaces, annealing furnaces, and scarfing machines to produce steel billets. They also heat treat and descale billets, and inspect them to ensure they meet quality standards.

What are the qualifications for a Scarf and Anneal Operator?

Most Scarf and Anneal Operators have an Associate’s Degree in a related field, such as metallurgy or manufacturing. They also have experience operating and maintaining melt furnaces, annealing furnaces, and scarfing machines.

What are the skills required for a Scarf and Anneal Operator?

Scarf and Anneal Operators must have a strong understanding of heat treating, descaling, and billet inspection processes. They must also be able to operate and maintain melt furnaces, annealing furnaces, and scarfing machines.

What is the work environment of a Scarf and Anneal Operator like?

Scarf and Anneal Operators typically work in a hot and noisy environment. They may also be exposed to fumes and chemicals.

What is the career outlook for a Scarf and Anneal Operator?

The career outlook for Scarf and Anneal Operators is expected to be good in the coming years. The demand for steel is expected to increase, which will lead to an increased need for Scarf and Anneal Operators.

What are the benefits of being a Scarf and Anneal Operator?

Scarf and Anneal Operators can earn a competitive salary and benefits package. They also have the opportunity to work with a variety of people and learn about different aspects of the steel industry.