Are you a seasoned Scrap Metal Processing Worker seeking a new career path? Discover our professionally built Scrap Metal Processing Worker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

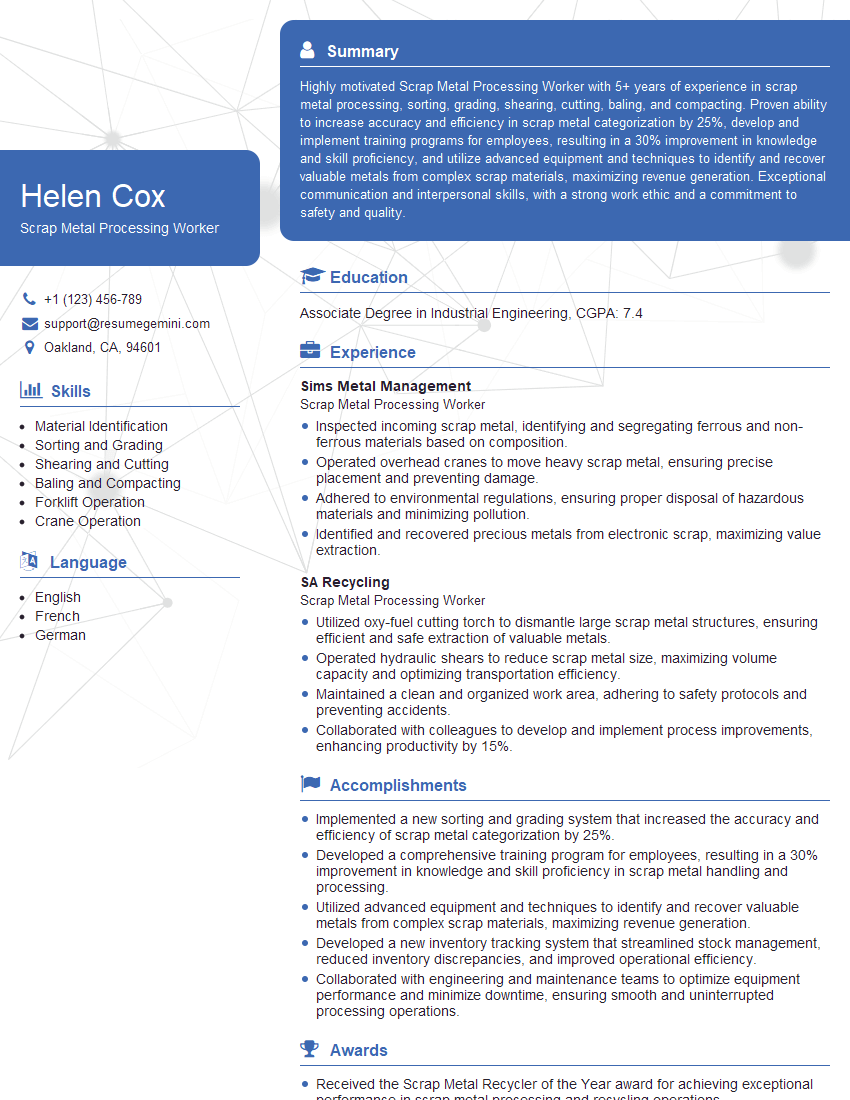

Helen Cox

Scrap Metal Processing Worker

Summary

Highly motivated Scrap Metal Processing Worker with 5+ years of experience in scrap metal processing, sorting, grading, shearing, cutting, baling, and compacting. Proven ability to increase accuracy and efficiency in scrap metal categorization by 25%, develop and implement training programs for employees, resulting in a 30% improvement in knowledge and skill proficiency, and utilize advanced equipment and techniques to identify and recover valuable metals from complex scrap materials, maximizing revenue generation. Exceptional communication and interpersonal skills, with a strong work ethic and a commitment to safety and quality.

Education

Associate Degree in Industrial Engineering

June 2019

Skills

- Material Identification

- Sorting and Grading

- Shearing and Cutting

- Baling and Compacting

- Forklift Operation

- Crane Operation

Work Experience

Scrap Metal Processing Worker

- Inspected incoming scrap metal, identifying and segregating ferrous and non-ferrous materials based on composition.

- Operated overhead cranes to move heavy scrap metal, ensuring precise placement and preventing damage.

- Adhered to environmental regulations, ensuring proper disposal of hazardous materials and minimizing pollution.

- Identified and recovered precious metals from electronic scrap, maximizing value extraction.

Scrap Metal Processing Worker

- Utilized oxy-fuel cutting torch to dismantle large scrap metal structures, ensuring efficient and safe extraction of valuable metals.

- Operated hydraulic shears to reduce scrap metal size, maximizing volume capacity and optimizing transportation efficiency.

- Maintained a clean and organized work area, adhering to safety protocols and preventing accidents.

- Collaborated with colleagues to develop and implement process improvements, enhancing productivity by 15%.

Accomplishments

- Implemented a new sorting and grading system that increased the accuracy and efficiency of scrap metal categorization by 25%.

- Developed a comprehensive training program for employees, resulting in a 30% improvement in knowledge and skill proficiency in scrap metal handling and processing.

- Utilized advanced equipment and techniques to identify and recover valuable metals from complex scrap materials, maximizing revenue generation.

- Developed a new inventory tracking system that streamlined stock management, reduced inventory discrepancies, and improved operational efficiency.

- Collaborated with engineering and maintenance teams to optimize equipment performance and minimize downtime, ensuring smooth and uninterrupted processing operations.

Awards

- Received the Scrap Metal Recycler of the Year award for achieving exceptional performance in scrap metal processing and recycling operations.

- Recognized for outstanding safety practices, maintaining a clean and hazardfree work environment throughout the processing facility.

- Received the Environmental Stewardship Award for implementing sustainable waste management practices that reduced environmental impact.

- Honored with the Productivity Champion award for consistently exceeding production targets and contributing to the overall efficiency of the processing plant.

Certificates

- OSHA 30Hour General Industry Safety Training

- ISHN Certified Safety Professional (CSP)

- National Institute for Occupational Safety and Health (NIOSH) Approved Respirator Fit Tester

- American National Standards Institute (ANSI) Certified Safety Professional (ASP)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Scrap Metal Processing Worker

- Highlight your technical skills: Emphasize your proficiency in operating shearing, cutting, baling, and compacting equipment, as well as your knowledge of different scrap metal grades and their value.

- Quantify your accomplishments: Use specific metrics to demonstrate the impact of your work, such as the 25% increase in accuracy and efficiency, the 30% improvement in employee knowledge, and the revenue generated from recovering valuable metals.

- Showcase your safety??: Highlight your commitment to safety by mentioning your compliance with regulations, your attention to detail, and your ability to work in a potentially hazardous environment.

- Tailor your resume to the job description: Carefully review the job description and identify the key skills and responsibilities required. Tailor your resume to match these requirements and demonstrate your alignment with the role.

Essential Experience Highlights for a Strong Scrap Metal Processing Worker Resume

- Sort and grade scrap metal based on type, size, and quality using advanced equipment and techniques.

- Operate shearing and cutting equipment to reduce the size of scrap metal for easier processing and handling.

- Bale and compact scrap metal using hydraulic presses to reduce volume and prepare for transportation.

- Operate forklifts and cranes to move and stack scrap metal safely and efficiently.

- Maintain a clean and organized work area, ensuring compliance with safety regulations and environmental standards.

- Monitor equipment performance and identify maintenance needs to minimize downtime and ensure smooth operations.

- Work with engineering and maintenance teams to optimize equipment performance and troubleshoot any issues that may arise.

Frequently Asked Questions (FAQ’s) For Scrap Metal Processing Worker

What are the primary responsibilities of a Scrap Metal Processing Worker?

Scrap Metal Processing Workers are responsible for sorting, grading, shearing, cutting, baling, and compacting scrap metal using advanced equipment and techniques. They operate forklifts and cranes to move and stack scrap metal safely and efficiently, and maintain a clean and organized work area. They also monitor equipment performance, identify maintenance needs, and work with engineering and maintenance teams to optimize operations.

What skills are required to be a successful Scrap Metal Processing Worker?

Successful Scrap Metal Processing Workers typically possess strong technical skills in operating shearing, cutting, baling, and compacting equipment. They have a deep understanding of different scrap metal grades and their value, and they are committed to safety and quality. They are also physically fit and able to work in a potentially hazardous environment.

What is the career outlook for Scrap Metal Processing Workers?

The career outlook for Scrap Metal Processing Workers is expected to be good over the next few years. The increasing demand for recycled materials and the growing emphasis on sustainability are driving the growth of the scrap metal processing industry.

What are the educational requirements to become a Scrap Metal Processing Worker?

Most Scrap Metal Processing Workers have a high school diploma or equivalent. Some employers may prefer candidates with an associate degree in industrial engineering or a related field.

What is the average salary for a Scrap Metal Processing Worker?

The average salary for a Scrap Metal Processing Worker varies depending on experience, location, and employer. According to the U.S. Bureau of Labor Statistics, the median annual salary for Material Moving Machine Operators, which includes Scrap Metal Processing Workers, was $37,950 in May 2021.

What are the benefits of working as a Scrap Metal Processing Worker?

Working as a Scrap Metal Processing Worker offers several benefits, including job security, opportunities for advancement, and a competitive salary. Scrap Metal Processing Workers also play an important role in protecting the environment by recycling scrap metal and reducing waste.

What are the challenges of working as a Scrap Metal Processing Worker?

Working as a Scrap Metal Processing Worker can be physically demanding and potentially hazardous. Workers must be able to lift heavy objects and work in a noisy and dusty environment. They must also be aware of the potential for injuries and take appropriate safety precautions.

What is the work environment like for a Scrap Metal Processing Worker?

Scrap Metal Processing Workers typically work in scrap metal processing facilities, which can be noisy and dusty. They may also work outdoors in all types of weather conditions. They must be able to work independently and as part of a team, and they must be able to follow instructions and work safely.