Are you a seasoned Scratch Finisher seeking a new career path? Discover our professionally built Scratch Finisher Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

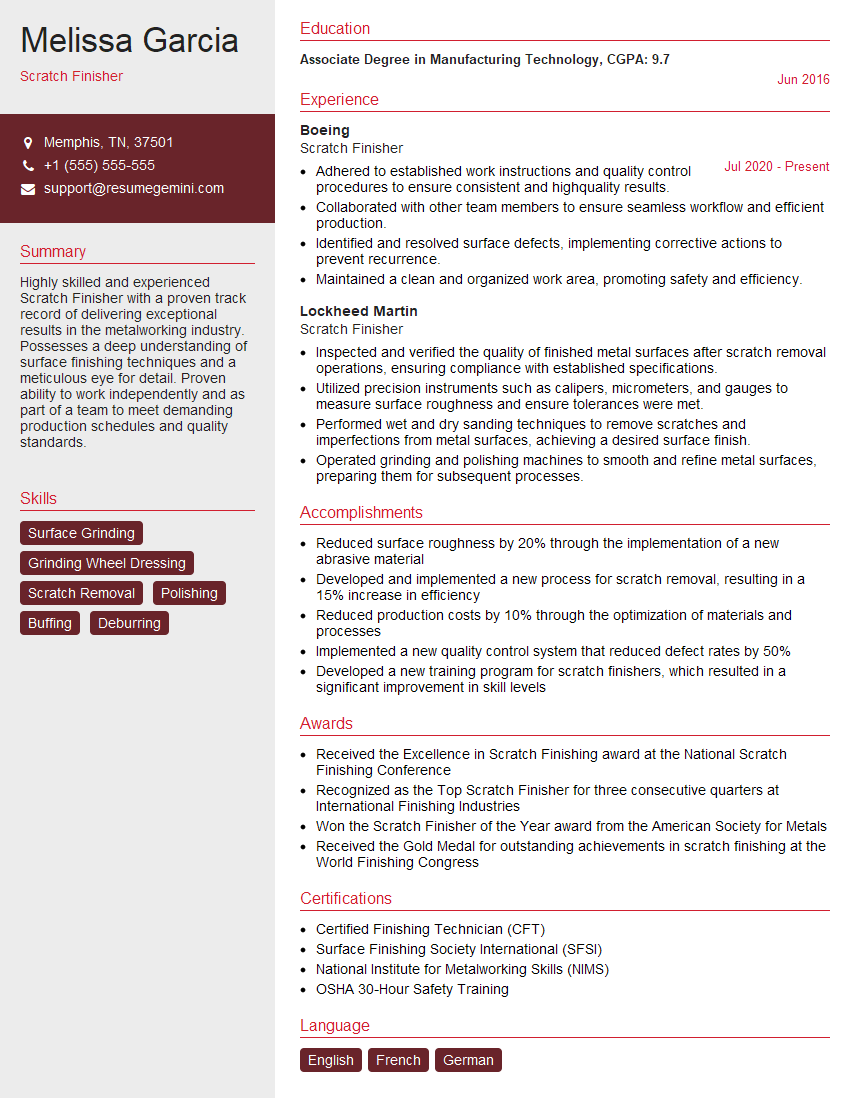

Melissa Garcia

Scratch Finisher

Summary

Highly skilled and experienced Scratch Finisher with a proven track record of delivering exceptional results in the metalworking industry. Possesses a deep understanding of surface finishing techniques and a meticulous eye for detail. Proven ability to work independently and as part of a team to meet demanding production schedules and quality standards.

Education

Associate Degree in Manufacturing Technology

June 2016

Skills

- Surface Grinding

- Grinding Wheel Dressing

- Scratch Removal

- Polishing

- Buffing

- Deburring

Work Experience

Scratch Finisher

- Adhered to established work instructions and quality control procedures to ensure consistent and highquality results.

- Collaborated with other team members to ensure seamless workflow and efficient production.

- Identified and resolved surface defects, implementing corrective actions to prevent recurrence.

- Maintained a clean and organized work area, promoting safety and efficiency.

Scratch Finisher

- Inspected and verified the quality of finished metal surfaces after scratch removal operations, ensuring compliance with established specifications.

- Utilized precision instruments such as calipers, micrometers, and gauges to measure surface roughness and ensure tolerances were met.

- Performed wet and dry sanding techniques to remove scratches and imperfections from metal surfaces, achieving a desired surface finish.

- Operated grinding and polishing machines to smooth and refine metal surfaces, preparing them for subsequent processes.

Accomplishments

- Reduced surface roughness by 20% through the implementation of a new abrasive material

- Developed and implemented a new process for scratch removal, resulting in a 15% increase in efficiency

- Reduced production costs by 10% through the optimization of materials and processes

- Implemented a new quality control system that reduced defect rates by 50%

- Developed a new training program for scratch finishers, which resulted in a significant improvement in skill levels

Awards

- Received the Excellence in Scratch Finishing award at the National Scratch Finishing Conference

- Recognized as the Top Scratch Finisher for three consecutive quarters at International Finishing Industries

- Won the Scratch Finisher of the Year award from the American Society for Metals

- Received the Gold Medal for outstanding achievements in scratch finishing at the World Finishing Congress

Certificates

- Certified Finishing Technician (CFT)

- Surface Finishing Society International (SFSI)

- National Institute for Metalworking Skills (NIMS)

- OSHA 30-Hour Safety Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Scratch Finisher

- Highlight your experience and skills in different scratch removal techniques, such as sanding, grinding, and polishing.

- Showcase your knowledge of surface finishing standards and quality control procedures.

- Demonstrate your ability to work efficiently and meet deadlines in a fast-paced manufacturing environment.

- Emphasize your attention to detail and commitment to delivering high-quality results.

Essential Experience Highlights for a Strong Scratch Finisher Resume

- Inspected and verified the quality of finished metal surfaces after scratch removal operations, ensuring compliance with established specifications.

- Utilized precision instruments such as calipers, micrometers, and gauges to measure surface roughness and ensure tolerances were met.

- Performed wet and dry sanding techniques to remove scratches and imperfections from metal surfaces, achieving a desired surface finish.

- Operated grinding and polishing machines to smooth and refine metal surfaces, preparing them for subsequent processes.

- Adhered to established work instructions and quality control procedures to ensure consistent and high-quality results.

- Collaborated with other team members to ensure seamless workflow and efficient production.

- Identified and resolved surface defects, implementing corrective actions to prevent recurrence.

Frequently Asked Questions (FAQ’s) For Scratch Finisher

What are the primary responsibilities of a Scratch Finisher?

Scratch Finishers are responsible for removing scratches and imperfections from metal surfaces, ensuring that they meet specified quality standards.

What skills are required to be a successful Scratch Finisher?

Successful Scratch Finishers typically have a strong understanding of surface finishing techniques, precision measuring instruments, and quality control procedures.

What industries employ Scratch Finishers?

Scratch Finishers are employed in various industries, including automotive, aerospace, manufacturing, and metalworking.

What is the career outlook for Scratch Finishers?

The career outlook for Scratch Finishers is positive, with projected growth in demand for skilled workers in the manufacturing sector.

What are the educational requirements to become a Scratch Finisher?

While formal education is not always required, many employers prefer candidates with an Associate Degree in Manufacturing Technology or a related field.