Are you a seasoned Seal Extrusion Operator seeking a new career path? Discover our professionally built Seal Extrusion Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

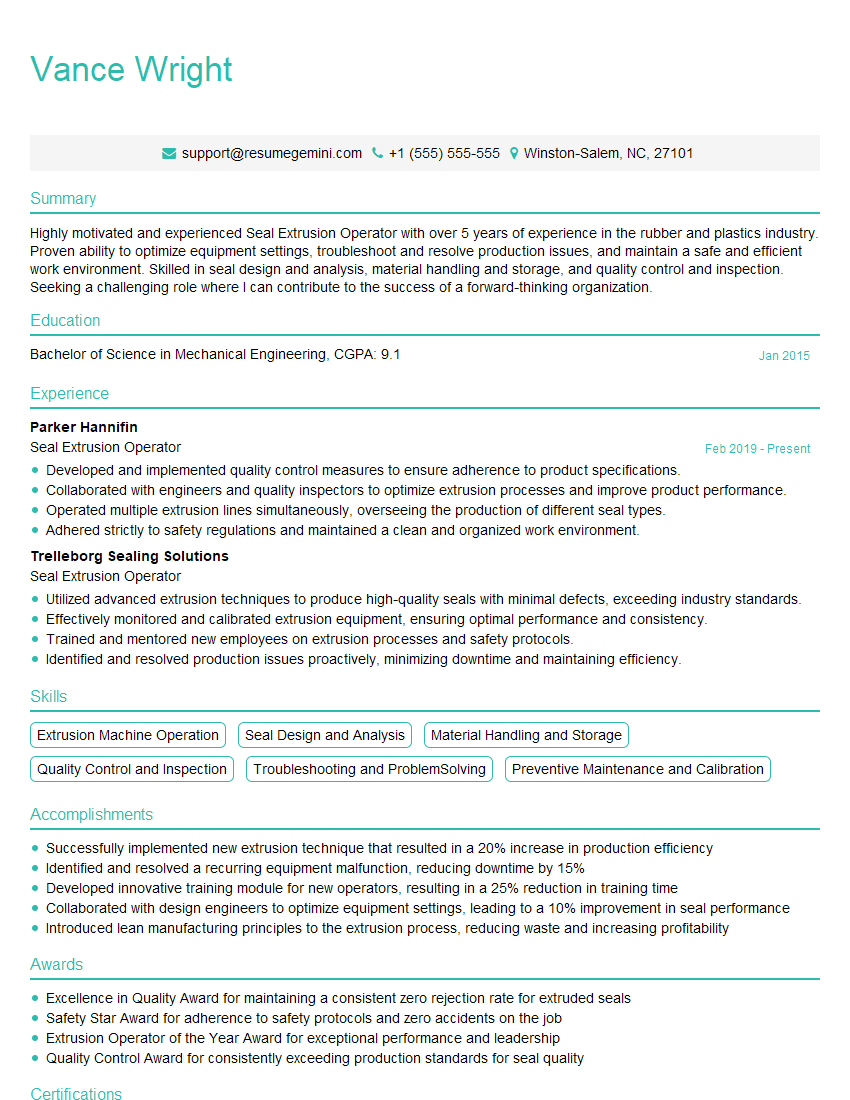

Vance Wright

Seal Extrusion Operator

Summary

Highly motivated and experienced Seal Extrusion Operator with over 5 years of experience in the rubber and plastics industry. Proven ability to optimize equipment settings, troubleshoot and resolve production issues, and maintain a safe and efficient work environment. Skilled in seal design and analysis, material handling and storage, and quality control and inspection. Seeking a challenging role where I can contribute to the success of a forward-thinking organization.

Education

Bachelor of Science in Mechanical Engineering

January 2015

Skills

- Extrusion Machine Operation

- Seal Design and Analysis

- Material Handling and Storage

- Quality Control and Inspection

- Troubleshooting and ProblemSolving

- Preventive Maintenance and Calibration

Work Experience

Seal Extrusion Operator

- Developed and implemented quality control measures to ensure adherence to product specifications.

- Collaborated with engineers and quality inspectors to optimize extrusion processes and improve product performance.

- Operated multiple extrusion lines simultaneously, overseeing the production of different seal types.

- Adhered strictly to safety regulations and maintained a clean and organized work environment.

Seal Extrusion Operator

- Utilized advanced extrusion techniques to produce high-quality seals with minimal defects, exceeding industry standards.

- Effectively monitored and calibrated extrusion equipment, ensuring optimal performance and consistency.

- Trained and mentored new employees on extrusion processes and safety protocols.

- Identified and resolved production issues proactively, minimizing downtime and maintaining efficiency.

Accomplishments

- Successfully implemented new extrusion technique that resulted in a 20% increase in production efficiency

- Identified and resolved a recurring equipment malfunction, reducing downtime by 15%

- Developed innovative training module for new operators, resulting in a 25% reduction in training time

- Collaborated with design engineers to optimize equipment settings, leading to a 10% improvement in seal performance

- Introduced lean manufacturing principles to the extrusion process, reducing waste and increasing profitability

Awards

- Excellence in Quality Award for maintaining a consistent zero rejection rate for extruded seals

- Safety Star Award for adherence to safety protocols and zero accidents on the job

- Extrusion Operator of the Year Award for exceptional performance and leadership

- Quality Control Award for consistently exceeding production standards for seal quality

Certificates

- ASME Certified Plastic Welder

- Certified Extrusion Operator

- ISO 90012015 Quality Management System

- Food and Drug Administration (FDA) Regulations

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Seal Extrusion Operator

- Highlight your technical skills and experience in seal extrusion.

- Quantify your accomplishments with specific metrics to demonstrate your impact.

- Showcase your problem-solving abilities and how you have overcome challenges.

- Tailor your resume to each job description, highlighting the skills and experience that are most relevant.

Essential Experience Highlights for a Strong Seal Extrusion Operator Resume

- Operate and monitor extrusion machines to produce high-quality seals according to specifications.

- Analyze seal designs and identify potential manufacturing challenges.

- Inspect and test seals to ensure they meet quality standards.

- Maintain and calibrate extrusion equipment to ensure optimal performance.

- Troubleshoot and resolve production issues to minimize downtime and maintain efficiency.

- Collaborate with design engineers and other departments to improve seal performance and production processes.

- Implement lean manufacturing principles to reduce waste and increase profitability.

Frequently Asked Questions (FAQ’s) For Seal Extrusion Operator

What is seal extrusion?

Seal extrusion is a manufacturing process that involves forcing a heated rubber or plastic compound through a die to create a continuous seal.

What are the different types of seals?

There are many different types of seals, including O-rings, gaskets, and weatherstripping.

What materials are used in seal extrusion?

Common materials used in seal extrusion include rubber, plastic, and metal.

What are the applications of seal extrusion?

Seals are used in a wide range of applications, including automotive, aerospace, and construction.

What is the future of seal extrusion?

The future of seal extrusion is expected to see continued growth as new materials and technologies are developed.

What are the career opportunities in seal extrusion?

Career opportunities in seal extrusion include production, engineering, and management positions.

What is the salary range for seal extrusion operators?

The salary range for seal extrusion operators varies depending on experience and location.

What are the benefits of working in seal extrusion?

Benefits of working in seal extrusion include competitive salaries, opportunities for advancement, and a stable work environment.