Are you a seasoned Second Class Welder seeking a new career path? Discover our professionally built Second Class Welder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

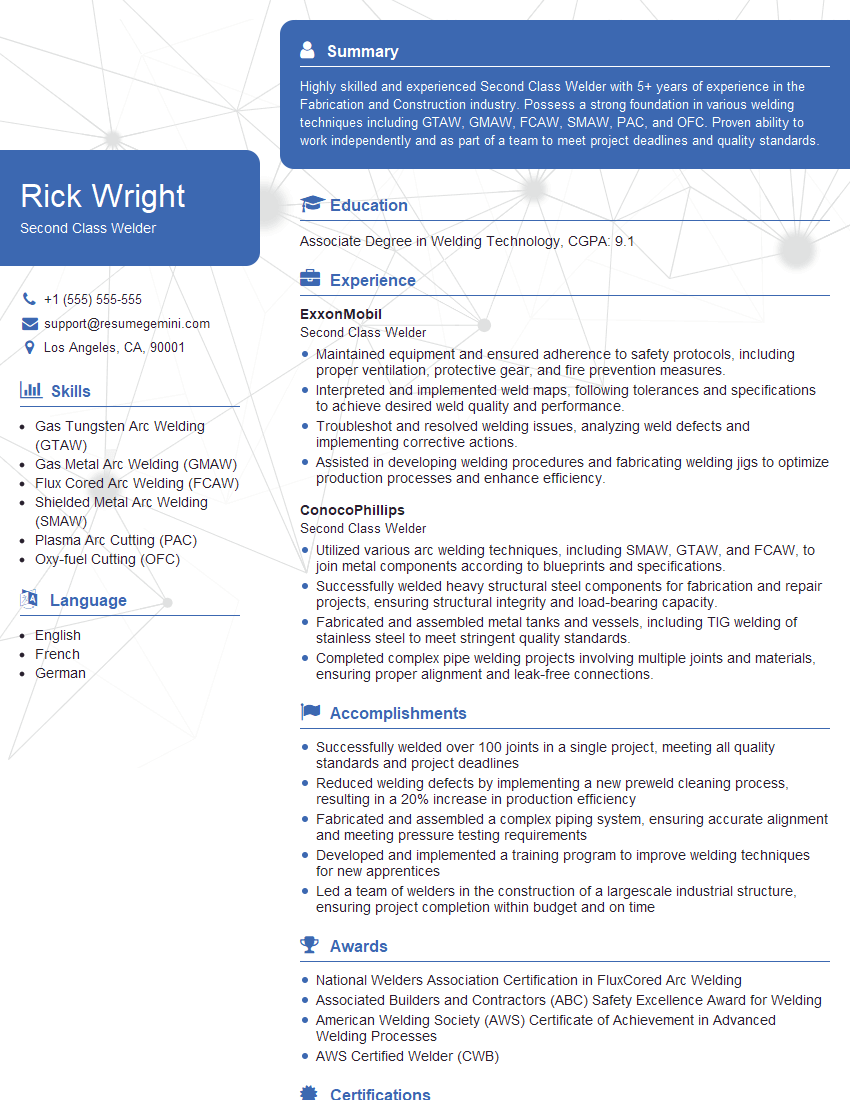

Rick Wright

Second Class Welder

Summary

Highly skilled and experienced Second Class Welder with 5+ years of experience in the Fabrication and Construction industry. Possess a strong foundation in various welding techniques including GTAW, GMAW, FCAW, SMAW, PAC, and OFC. Proven ability to work independently and as part of a team to meet project deadlines and quality standards.

Education

Associate Degree in Welding Technology

February 2017

Skills

- Gas Tungsten Arc Welding (GTAW)

- Gas Metal Arc Welding (GMAW)

- Flux Cored Arc Welding (FCAW)

- Shielded Metal Arc Welding (SMAW)

- Plasma Arc Cutting (PAC)

- Oxy-fuel Cutting (OFC)

Work Experience

Second Class Welder

- Maintained equipment and ensured adherence to safety protocols, including proper ventilation, protective gear, and fire prevention measures.

- Interpreted and implemented weld maps, following tolerances and specifications to achieve desired weld quality and performance.

- Troubleshot and resolved welding issues, analyzing weld defects and implementing corrective actions.

- Assisted in developing welding procedures and fabricating welding jigs to optimize production processes and enhance efficiency.

Second Class Welder

- Utilized various arc welding techniques, including SMAW, GTAW, and FCAW, to join metal components according to blueprints and specifications.

- Successfully welded heavy structural steel components for fabrication and repair projects, ensuring structural integrity and load-bearing capacity.

- Fabricated and assembled metal tanks and vessels, including TIG welding of stainless steel to meet stringent quality standards.

- Completed complex pipe welding projects involving multiple joints and materials, ensuring proper alignment and leak-free connections.

Accomplishments

- Successfully welded over 100 joints in a single project, meeting all quality standards and project deadlines

- Reduced welding defects by implementing a new preweld cleaning process, resulting in a 20% increase in production efficiency

- Fabricated and assembled a complex piping system, ensuring accurate alignment and meeting pressure testing requirements

- Developed and implemented a training program to improve welding techniques for new apprentices

- Led a team of welders in the construction of a largescale industrial structure, ensuring project completion within budget and on time

Awards

- National Welders Association Certification in FluxCored Arc Welding

- Associated Builders and Contractors (ABC) Safety Excellence Award for Welding

- American Welding Society (AWS) Certificate of Achievement in Advanced Welding Processes

- AWS Certified Welder (CWB)

Certificates

- AWS Certified Welder (CWI)

- ASME Boiler and Pressure Vessel Code

- National Board of Boiler and Pressure Vessel Inspectors (NBBI)

- American Welding Society (AWS)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Second Class Welder

- Highlight your welding certifications and training, as they demonstrate your skills and commitment to the profession.

- Showcase your experience in specific industries, such as oil and gas, construction, or manufacturing, to demonstrate your knowledge of industry-specific welding requirements.

- Include quantifiable results in your resume, such as the number of welds completed or the percentage of welds that passed inspection, to demonstrate your productivity and quality of work.

- Proofread your resume carefully for any errors, as attention to detail is essential in welding.

Essential Experience Highlights for a Strong Second Class Welder Resume

- Interpret engineering drawings, blueprints, and welding procedures to ensure accurate fabrication and assembly.

- Set up and operate welding equipment, including wire feeders, gas regulators, and plasma cutters.

- Weld a variety of metals, including carbon steel, stainless steel, and aluminum, using appropriate welding techniques.

- Inspect welds for quality and conformance to specifications, using visual inspection and non-destructive testing methods.

- Maintain a clean and organized work area, and adhere to all safety regulations and protocols.

- Troubleshoot and resolve welding issues, ensuring minimal downtime and efficient production.

Frequently Asked Questions (FAQ’s) For Second Class Welder

What is the difference between a Second Class Welder and a First Class Welder?

A Second Class Welder is qualified to perform welding tasks under the supervision of a First Class Welder. They typically have less experience and are not yet certified to work independently. A First Class Welder, on the other hand, has passed advanced welding tests and is authorized to work without supervision.

What are the career prospects for Second Class Welders?

Second Class Welders can advance their careers by gaining experience and obtaining additional certifications. They may eventually qualify for promotion to First Class Welder or pursue specialized welding roles, such as Underwater Welder or Welding Inspector.

What is the average salary for Second Class Welders?

The average salary for Second Class Welders varies depending on factors such as experience, location, and industry. According to the U.S. Bureau of Labor Statistics, the median annual wage for Welders, Cutters, and Welder Fitters was $47,610 in May 2021.

What are the physical demands of being a Second Class Welder?

Second Class Welders must be able to stand for long periods, lift heavy objects, and work in awkward positions. They must also be able to tolerate heat, fumes, and noise.

What safety precautions should Second Class Welders take?

Second Class Welders must follow all safety regulations and protocols, including wearing appropriate protective gear, such as welding helmets, gloves, and respirators. They should also be aware of the potential hazards of welding, such as electrical shock, burns, and eye damage.