Are you a seasoned Semiconductor Wafers and Components Plater seeking a new career path? Discover our professionally built Semiconductor Wafers and Components Plater Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

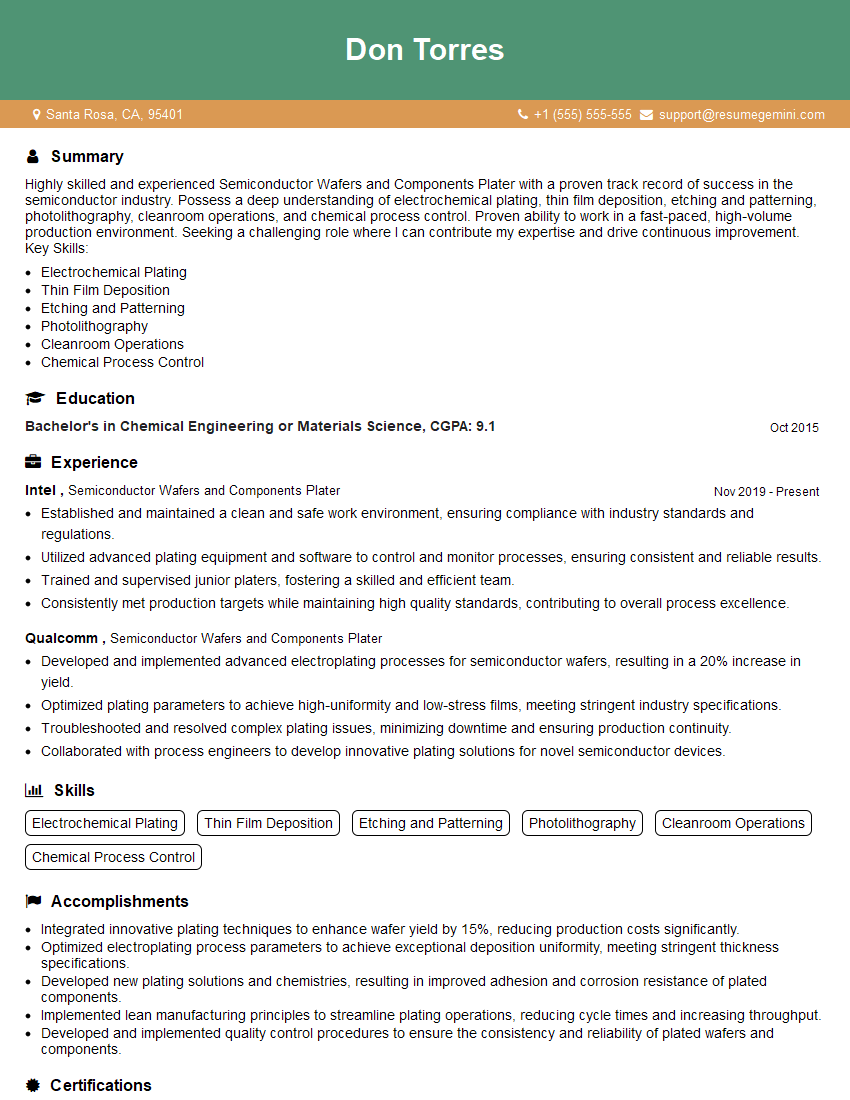

Don Torres

Semiconductor Wafers and Components Plater

Summary

Highly skilled and experienced Semiconductor Wafers and Components Plater with a proven track record of success in the semiconductor industry. Possess a deep understanding of electrochemical plating, thin film deposition, etching and patterning, photolithography, cleanroom operations, and chemical process control. Proven ability to work in a fast-paced, high-volume production environment. Seeking a challenging role where I can contribute my expertise and drive continuous improvement.

Key Skills:

- Electrochemical Plating

- Thin Film Deposition

- Etching and Patterning

- Photolithography

- Cleanroom Operations

- Chemical Process Control

Education

Bachelor’s in Chemical Engineering or Materials Science

October 2015

Skills

- Electrochemical Plating

- Thin Film Deposition

- Etching and Patterning

- Photolithography

- Cleanroom Operations

- Chemical Process Control

Work Experience

Semiconductor Wafers and Components Plater

- Established and maintained a clean and safe work environment, ensuring compliance with industry standards and regulations.

- Utilized advanced plating equipment and software to control and monitor processes, ensuring consistent and reliable results.

- Trained and supervised junior platers, fostering a skilled and efficient team.

- Consistently met production targets while maintaining high quality standards, contributing to overall process excellence.

Semiconductor Wafers and Components Plater

- Developed and implemented advanced electroplating processes for semiconductor wafers, resulting in a 20% increase in yield.

- Optimized plating parameters to achieve high-uniformity and low-stress films, meeting stringent industry specifications.

- Troubleshooted and resolved complex plating issues, minimizing downtime and ensuring production continuity.

- Collaborated with process engineers to develop innovative plating solutions for novel semiconductor devices.

Accomplishments

- Integrated innovative plating techniques to enhance wafer yield by 15%, reducing production costs significantly.

- Optimized electroplating process parameters to achieve exceptional deposition uniformity, meeting stringent thickness specifications.

- Developed new plating solutions and chemistries, resulting in improved adhesion and corrosion resistance of plated components.

- Implemented lean manufacturing principles to streamline plating operations, reducing cycle times and increasing throughput.

- Developed and implemented quality control procedures to ensure the consistency and reliability of plated wafers and components.

Certificates

- Semiconductor Manufacturing Technician (SMT) Certification

- Electrochemical Plating Technician Certification

- Cleanroom Technician Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Semiconductor Wafers and Components Plater

- Highlight your experience and skills in electrochemical plating, thin film deposition, and other relevant techniques.

- Quantify your accomplishments with specific metrics and results whenever possible.

- Demonstrate your knowledge of cleanroom operations and safety protocols.

- Tailor your resume to each specific job you apply for, highlighting the skills and experience most relevant to the position.

Essential Experience Highlights for a Strong Semiconductor Wafers and Components Plater Resume

- Operate and maintain electrochemical plating equipment to deposit thin films on semiconductor wafers.

- Etch and pattern wafers using photolithography techniques to create desired circuit patterns.

- Control and monitor chemical processes to ensure consistent and high-quality results.

- Troubleshoot and resolve technical issues related to plating, etching, and patterning processes.

- Maintain a clean and organized work environment in accordance with cleanroom protocols.

- Adhere to safety regulations and industry best practices to ensure a safe and efficient work environment.

Frequently Asked Questions (FAQ’s) For Semiconductor Wafers and Components Plater

What is the role of a Semiconductor Wafers and Components Plater?

A Semiconductor Wafers and Components Plater is responsible for depositing thin films on semiconductor wafers using electrochemical plating and other techniques. They also perform etching and patterning processes to create the desired circuit patterns on the wafers.

What are the key skills required for this role?

Key skills include electrochemical plating, thin film deposition, etching and patterning, photolithography, cleanroom operations, and chemical process control.

What is the work environment like for a Semiconductor Wafers and Components Plater?

Semiconductor Wafers and Components Platers typically work in cleanrooms and must adhere to strict safety protocols.

What are the career prospects for a Semiconductor Wafers and Components Plater?

Semiconductor Wafers and Components Platers with experience and expertise can advance to roles such as process engineers, quality control engineers, or production managers.

What is the salary range for a Semiconductor Wafers and Components Plater?

The salary range for a Semiconductor Wafers and Components Plater varies depending on experience, location, and company. According to Indeed, the average salary for a Semiconductor Wafers and Components Plater is around $75,000 per year.

What are the educational requirements for this role?

Most Semiconductor Wafers and Components Platers have a Bachelor’s degree in Chemical Engineering or Materials Science.