Are you a seasoned Semiconductor Wafers Diffusion Furnace Operator seeking a new career path? Discover our professionally built Semiconductor Wafers Diffusion Furnace Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

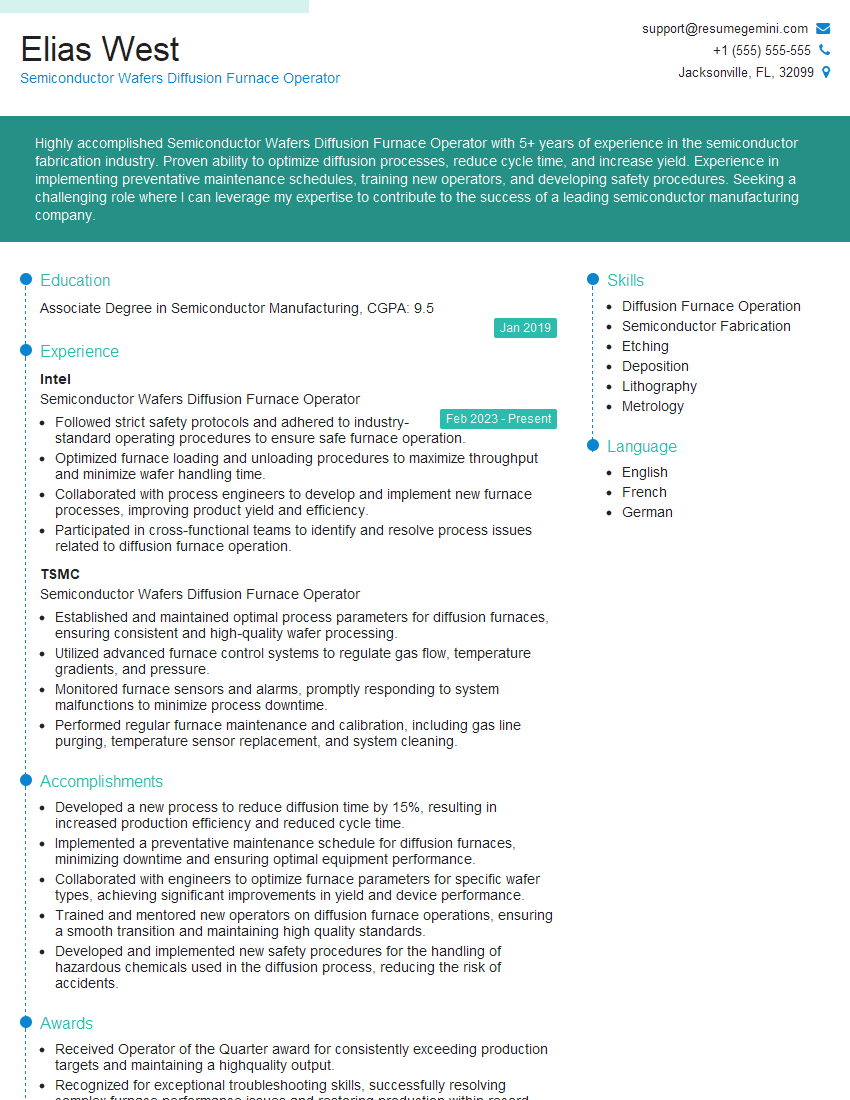

Elias West

Semiconductor Wafers Diffusion Furnace Operator

Summary

Highly accomplished Semiconductor Wafers Diffusion Furnace Operator with 5+ years of experience in the semiconductor fabrication industry. Proven ability to optimize diffusion processes, reduce cycle time, and increase yield. Experience in implementing preventative maintenance schedules, training new operators, and developing safety procedures. Seeking a challenging role where I can leverage my expertise to contribute to the success of a leading semiconductor manufacturing company.

Education

Associate Degree in Semiconductor Manufacturing

January 2019

Skills

- Diffusion Furnace Operation

- Semiconductor Fabrication

- Etching

- Deposition

- Lithography

- Metrology

Work Experience

Semiconductor Wafers Diffusion Furnace Operator

- Followed strict safety protocols and adhered to industry-standard operating procedures to ensure safe furnace operation.

- Optimized furnace loading and unloading procedures to maximize throughput and minimize wafer handling time.

- Collaborated with process engineers to develop and implement new furnace processes, improving product yield and efficiency.

- Participated in cross-functional teams to identify and resolve process issues related to diffusion furnace operation.

Semiconductor Wafers Diffusion Furnace Operator

- Established and maintained optimal process parameters for diffusion furnaces, ensuring consistent and high-quality wafer processing.

- Utilized advanced furnace control systems to regulate gas flow, temperature gradients, and pressure.

- Monitored furnace sensors and alarms, promptly responding to system malfunctions to minimize process downtime.

- Performed regular furnace maintenance and calibration, including gas line purging, temperature sensor replacement, and system cleaning.

Accomplishments

- Developed a new process to reduce diffusion time by 15%, resulting in increased production efficiency and reduced cycle time.

- Implemented a preventative maintenance schedule for diffusion furnaces, minimizing downtime and ensuring optimal equipment performance.

- Collaborated with engineers to optimize furnace parameters for specific wafer types, achieving significant improvements in yield and device performance.

- Trained and mentored new operators on diffusion furnace operations, ensuring a smooth transition and maintaining high quality standards.

- Developed and implemented new safety procedures for the handling of hazardous chemicals used in the diffusion process, reducing the risk of accidents.

Awards

- Received Operator of the Quarter award for consistently exceeding production targets and maintaining a highquality output.

- Recognized for exceptional troubleshooting skills, successfully resolving complex furnace performance issues and restoring production within record time.

- Received Safety Champion award for consistently adhering to safety protocols and promoting a safe work environment.

- Recognized for contributions to a team project that developed a new diffusion process, increasing device reliability and yield.

Certificates

- Certified Semiconductor Manufacturing Technician (CSMT)

- Diffusion Furnace Operator Certification

- Semiconductor Process Control Certification

- Cleanroom Procedures Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Semiconductor Wafers Diffusion Furnace Operator

- Highlight your experience in developing and optimizing diffusion processes.

- Quantify your accomplishments whenever possible.

- Demonstrate your ability to work independently and as part of a team.

- Emphasize your commitment to safety and quality.

Essential Experience Highlights for a Strong Semiconductor Wafers Diffusion Furnace Operator Resume

- Operate and maintain diffusion furnaces used in the semiconductor fabrication process.

- Develop and optimize diffusion processes to improve yield and device performance.

- Implement preventative maintenance schedules to minimize downtime and ensure optimal equipment performance.

- Train and mentor new operators on diffusion furnace operations.

- Develop and implement safety procedures to reduce the risk of accidents.

- Collaborate with engineers to solve technical problems and improve process efficiency.

- Monitor and control process parameters to ensure product quality and meet customer specifications.

Frequently Asked Questions (FAQ’s) For Semiconductor Wafers Diffusion Furnace Operator

What is the role of a Semiconductor Wafers Diffusion Furnace Operator?

A Semiconductor Wafers Diffusion Furnace Operator is responsible for operating and maintaining diffusion furnaces, which are used to diffuse impurities into semiconductor wafers. This process is critical in the production of semiconductor devices, such as transistors and integrated circuits.

What are the key skills required for this role?

Key skills for a Semiconductor Wafers Diffusion Furnace Operator include knowledge of semiconductor fabrication processes, diffusion furnace operation, and safety procedures. They should also have strong analytical and problem-solving skills, as well as the ability to work independently and as part of a team.

What are the career prospects for this role?

Semiconductor Wafers Diffusion Furnace Operators can advance to roles such as Process Engineer, Production Supervisor, or Quality Control Manager. With experience and additional training, they may also move into management or research and development roles.

What is the typical salary for this role?

The salary for a Semiconductor Wafers Diffusion Furnace Operator can vary depending on experience, location, and company size. According to Salary.com, the average salary for this role in the United States is around $60,000 per year.

What are the benefits of working as a Semiconductor Wafers Diffusion Furnace Operator?

Benefits of working as a Semiconductor Wafers Diffusion Furnace Operator include competitive salaries, opportunities for career advancement, and the chance to work in a high-tech industry. They also have the opportunity to make a significant contribution to the development of new technologies.

What are the challenges of working as a Semiconductor Wafers Diffusion Furnace Operator?

Challenges of working as a Semiconductor Wafers Diffusion Furnace Operator include working in a cleanroom environment, adhering to strict safety protocols, and meeting high production standards. They may also need to work overtime or on weekends to meet production demands.

What is the job outlook for this role?

The job outlook for Semiconductor Wafers Diffusion Furnace Operators is expected to be good over the next few years. The increasing demand for semiconductors is expected to lead to increased production, which in turn will create more jobs for operators.

What are some tips for writing a standout resume for this role?

Tips for writing a standout resume for a Semiconductor Wafers Diffusion Furnace Operator include highlighting your experience in operating and maintaining diffusion furnaces, quantifying your accomplishments, demonstrating your commitment to safety and quality, and tailoring your resume to the specific job you are applying for.