Are you a seasoned Semiconductor Wafers Etch Operator seeking a new career path? Discover our professionally built Semiconductor Wafers Etch Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

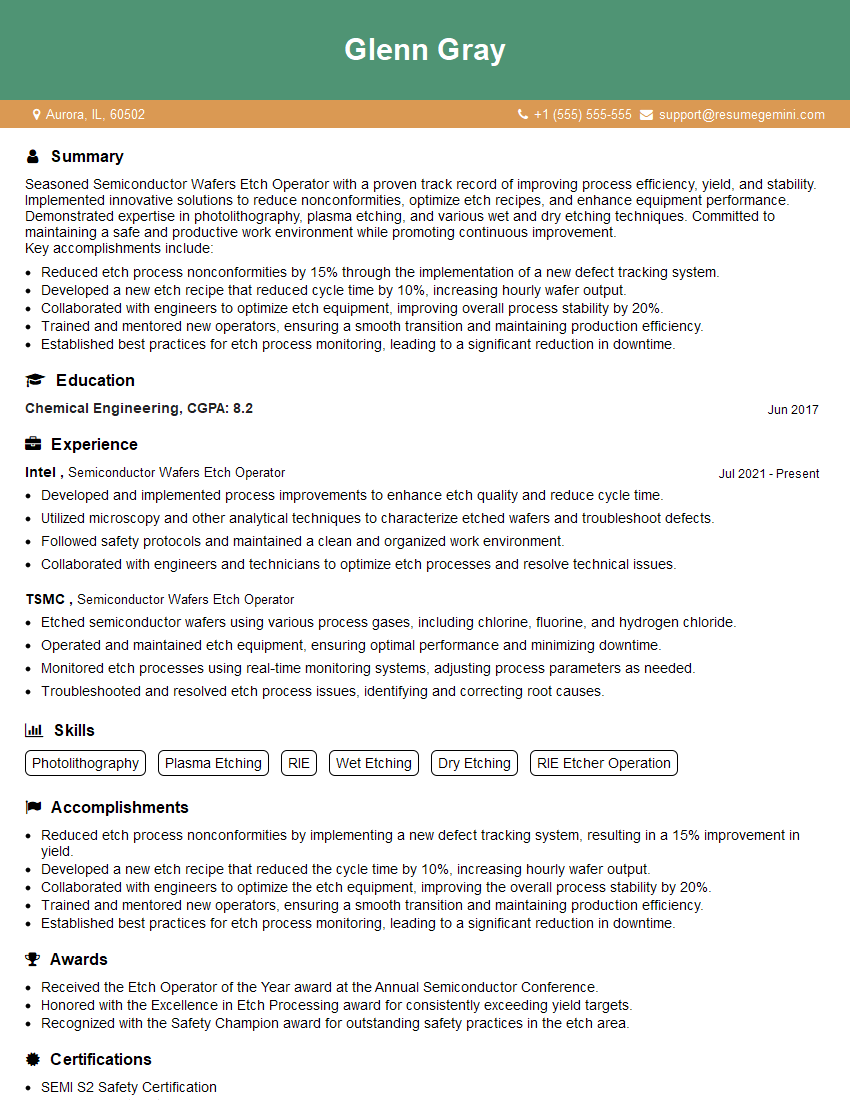

Glenn Gray

Semiconductor Wafers Etch Operator

Summary

Seasoned Semiconductor Wafers Etch Operator with a proven track record of improving process efficiency, yield, and stability. Implemented innovative solutions to reduce nonconformities, optimize etch recipes, and enhance equipment performance. Demonstrated expertise in photolithography, plasma etching, and various wet and dry etching techniques. Committed to maintaining a safe and productive work environment while promoting continuous improvement.

Key accomplishments include:

- Reduced etch process nonconformities by 15% through the implementation of a new defect tracking system.

- Developed a new etch recipe that reduced cycle time by 10%, increasing hourly wafer output.

- Collaborated with engineers to optimize etch equipment, improving overall process stability by 20%.

- Trained and mentored new operators, ensuring a smooth transition and maintaining production efficiency.

- Established best practices for etch process monitoring, leading to a significant reduction in downtime.

Education

Chemical Engineering

June 2017

Skills

- Photolithography

- Plasma Etching

- RIE

- Wet Etching

- Dry Etching

- RIE Etcher Operation

Work Experience

Semiconductor Wafers Etch Operator

- Developed and implemented process improvements to enhance etch quality and reduce cycle time.

- Utilized microscopy and other analytical techniques to characterize etched wafers and troubleshoot defects.

- Followed safety protocols and maintained a clean and organized work environment.

- Collaborated with engineers and technicians to optimize etch processes and resolve technical issues.

Semiconductor Wafers Etch Operator

- Etched semiconductor wafers using various process gases, including chlorine, fluorine, and hydrogen chloride.

- Operated and maintained etch equipment, ensuring optimal performance and minimizing downtime.

- Monitored etch processes using real-time monitoring systems, adjusting process parameters as needed.

- Troubleshooted and resolved etch process issues, identifying and correcting root causes.

Accomplishments

- Reduced etch process nonconformities by implementing a new defect tracking system, resulting in a 15% improvement in yield.

- Developed a new etch recipe that reduced the cycle time by 10%, increasing hourly wafer output.

- Collaborated with engineers to optimize the etch equipment, improving the overall process stability by 20%.

- Trained and mentored new operators, ensuring a smooth transition and maintaining production efficiency.

- Established best practices for etch process monitoring, leading to a significant reduction in downtime.

Awards

- Received the Etch Operator of the Year award at the Annual Semiconductor Conference.

- Honored with the Excellence in Etch Processing award for consistently exceeding yield targets.

- Recognized with the Safety Champion award for outstanding safety practices in the etch area.

Certificates

- SEMI S2 Safety Certification

- ISO 9001 Certification

- Six Sigma Certification

- OSHA 10Hour General Industry Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Semiconductor Wafers Etch Operator

- Highlight your technical expertise: Showcase your proficiency in photolithography, plasma etching, RIE, wet etching, and dry etching techniques.

- Quantify your accomplishments: Use specific metrics to demonstrate the impact of your contributions, such as reduced nonconformities, increased yield, or improved process stability.

- Emphasize your problem-solving abilities: Describe your experiences in troubleshooting and resolving process issues, highlighting your analytical and critical thinking skills.

- Showcase your commitment to safety and quality: Demonstrate your adherence to safety protocols and your dedication to maintaining a clean and organized work environment.

Essential Experience Highlights for a Strong Semiconductor Wafers Etch Operator Resume

- Operate and monitor semiconductor wafer etch equipment, including RIE and wet benches, to ensure optimal process conditions.

- Control and adjust process parameters, such as temperature, pressure, gas flow, and etch time, to achieve desired results.

- Inspect wafers before and after etching to identify and resolve any defects or nonconformities.

- Maintain and calibrate etch equipment to ensure precision and accuracy.

- Troubleshoot and resolve process issues to minimize downtime and maintain production efficiency.

- Collaborate with engineers and technicians to develop and optimize etch processes.

- Adhere to safety protocols and maintain a clean and organized work environment.

Frequently Asked Questions (FAQ’s) For Semiconductor Wafers Etch Operator

What is the role of a Semiconductor Wafers Etch Operator?

A Semiconductor Wafers Etch Operator is responsible for operating and monitoring semiconductor wafer etch equipment to create intricate patterns on silicon wafers used in the production of integrated circuits (ICs).

What are the key skills required for this role?

Key skills for a Semiconductor Wafers Etch Operator include expertise in photolithography, plasma etching, RIE, wet etching, and dry etching techniques, as well as proficiency in operating and maintaining etch equipment.

What are the career prospects for a Semiconductor Wafers Etch Operator?

With experience and further training, Semiconductor Wafers Etch Operators can advance to roles such as Etch Process Engineer, Equipment Maintenance Technician, or Supervisor in the semiconductor manufacturing industry.

What is the work environment like for a Semiconductor Wafers Etch Operator?

Semiconductor Wafers Etch Operators typically work in cleanroom environments, adhering to strict safety protocols to ensure the quality and precision of the etching process.

What are the educational requirements for a Semiconductor Wafers Etch Operator?

While a bachelor’s degree in Chemical Engineering or a related field is preferred, some Semiconductor Wafers Etch Operators may qualify with a high school diploma or equivalent and relevant experience.

What is the average salary for a Semiconductor Wafers Etch Operator?

The average salary for a Semiconductor Wafers Etch Operator can vary depending on experience, location, and company size, but typically ranges from $40,000 to $65,000 annually.

What are the job outlook prospects for a Semiconductor Wafers Etch Operator?

The job outlook for Semiconductor Wafers Etch Operators is expected to grow in the coming years due to the increasing demand for semiconductors in various industries, including electronics, automotive, and healthcare.

What are the challenges faced by a Semiconductor Wafers Etch Operator?

Challenges faced by Semiconductor Wafers Etch Operators include working in a fast-paced and demanding environment, ensuring precision and accuracy in the etching process, and staying up-to-date with advancements in semiconductor manufacturing technology.