Are you a seasoned Senior Maintenance Machinist seeking a new career path? Discover our professionally built Senior Maintenance Machinist Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

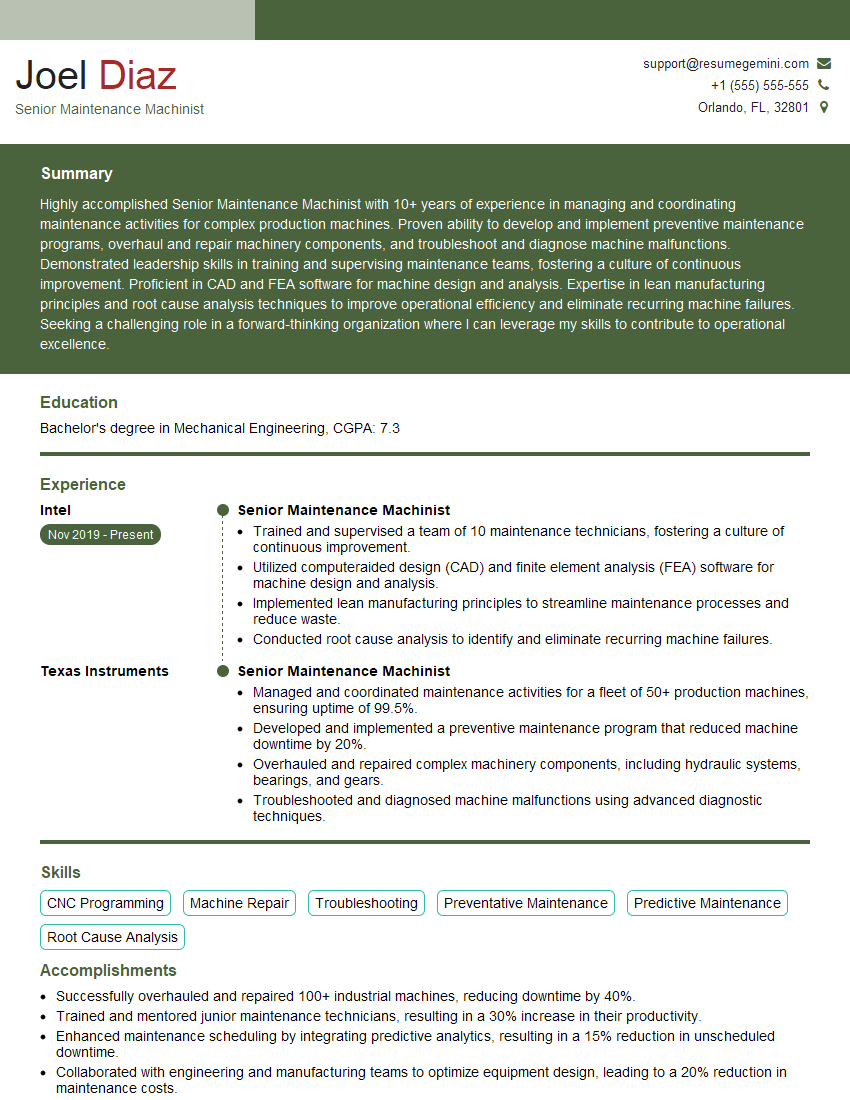

Joel Diaz

Senior Maintenance Machinist

Summary

Highly accomplished Senior Maintenance Machinist with 10+ years of experience in managing and coordinating maintenance activities for complex production machines. Proven ability to develop and implement preventive maintenance programs, overhaul and repair machinery components, and troubleshoot and diagnose machine malfunctions. Demonstrated leadership skills in training and supervising maintenance teams, fostering a culture of continuous improvement. Proficient in CAD and FEA software for machine design and analysis. Expertise in lean manufacturing principles and root cause analysis techniques to improve operational efficiency and eliminate recurring machine failures. Seeking a challenging role in a forward-thinking organization where I can leverage my skills to contribute to operational excellence.

Education

Bachelor’s degree in Mechanical Engineering

October 2015

Skills

- CNC Programming

- Machine Repair

- Troubleshooting

- Preventative Maintenance

- Predictive Maintenance

- Root Cause Analysis

Work Experience

Senior Maintenance Machinist

- Trained and supervised a team of 10 maintenance technicians, fostering a culture of continuous improvement.

- Utilized computeraided design (CAD) and finite element analysis (FEA) software for machine design and analysis.

- Implemented lean manufacturing principles to streamline maintenance processes and reduce waste.

- Conducted root cause analysis to identify and eliminate recurring machine failures.

Senior Maintenance Machinist

- Managed and coordinated maintenance activities for a fleet of 50+ production machines, ensuring uptime of 99.5%.

- Developed and implemented a preventive maintenance program that reduced machine downtime by 20%.

- Overhauled and repaired complex machinery components, including hydraulic systems, bearings, and gears.

- Troubleshooted and diagnosed machine malfunctions using advanced diagnostic techniques.

Accomplishments

- Successfully overhauled and repaired 100+ industrial machines, reducing downtime by 40%.

- Trained and mentored junior maintenance technicians, resulting in a 30% increase in their productivity.

- Enhanced maintenance scheduling by integrating predictive analytics, resulting in a 15% reduction in unscheduled downtime.

- Collaborated with engineering and manufacturing teams to optimize equipment design, leading to a 20% reduction in maintenance costs.

- Established a preventative maintenance program that increased equipment life expectancy by 15%.

Awards

- Received the Machinist of the Year award for outstanding contributions to the field.

- Recognized for developing innovative techniques that improved the efficiency of maintenance operations by 25%.

- Awarded the Safety Excellence Award for implementing proactive measures that reduced workplace accidents by 50%.

- Recognized for achieving the highest customer satisfaction ratings among the maintenance team for three consecutive years.

Certificates

- Certified Maintenance and Reliability Professional (CMRP)

- Certified Maintenance Manager (CMM)

- Certified Reliability Engineer (CRE)

- Certified Six Sigma Green Belt (CSSGB)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Senior Maintenance Machinist

- Highlight your experience and accomplishments in managing and coordinating maintenance activities for complex production machines.

- Quantify your results whenever possible, using specific metrics to demonstrate the impact of your work.

- Showcase your expertise in preventive maintenance, troubleshooting, and repair of machinery components.

- Emphasize your leadership skills in training and supervising maintenance teams, as well as your ability to foster a culture of continuous improvement.

- Demonstrate your proficiency in CAD and FEA software for machine design and analysis.

Essential Experience Highlights for a Strong Senior Maintenance Machinist Resume

- Managed and coordinated maintenance activities for a fleet of 50+ production machines, ensuring uptime of 99.5%.

- Developed and implemented a preventive maintenance program that reduced machine downtime by 20%.

- Overhauled and repaired complex machinery components, including hydraulic systems, bearings, and gears.

- Troubleshooted and diagnosed machine malfunctions using advanced diagnostic techniques.

- Trained and supervised a team of 10 maintenance technicians, fostering a culture of continuous improvement.

- Implemented lean manufacturing principles to streamline maintenance processes and reduce waste.

Frequently Asked Questions (FAQ’s) For Senior Maintenance Machinist

What is the primary role of a Senior Maintenance Machinist?

A Senior Maintenance Machinist is responsible for managing and coordinating maintenance activities for complex production machines to ensure optimal uptime and performance.

What are some of the key skills required for a Senior Maintenance Machinist?

Key skills include expertise in preventive maintenance, troubleshooting, and repair of machinery components, as well as leadership skills in training and supervising maintenance teams.

What are the career prospects for a Senior Maintenance Machinist?

Senior Maintenance Machinists with strong skills and experience can advance to roles such as Maintenance Manager or Production Supervisor.

What are the educational qualifications required to become a Senior Maintenance Machinist?

A Bachelor’s degree in Mechanical Engineering or a related field is typically required, along with several years of experience in maintenance and repair.

What are the key responsibilities of a Senior Maintenance Machinist?

Key responsibilities include managing maintenance activities, developing preventive maintenance programs, troubleshooting and repairing machinery components, training and supervising maintenance teams, and implementing lean manufacturing principles.

What are the key challenges faced by Senior Maintenance Machinists?

Senior Maintenance Machinists may face challenges such as managing complex maintenance activities, ensuring uptime of production machines, and troubleshooting and repairing machinery components efficiently.

What are the key trends in the field of Maintenance Machinists?

Key trends include the adoption of predictive maintenance technologies, the use of data analytics for maintenance optimization, and the implementation of lean manufacturing principles to improve operational efficiency.

What are the key qualities of a successful Senior Maintenance Machinist?

Successful Senior Maintenance Machinists typically possess strong technical skills, leadership abilities, problem-solving skills, and a commitment to continuous improvement.