Are you a seasoned Set-Up and Lay-Out Inspector seeking a new career path? Discover our professionally built Set-Up and Lay-Out Inspector Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

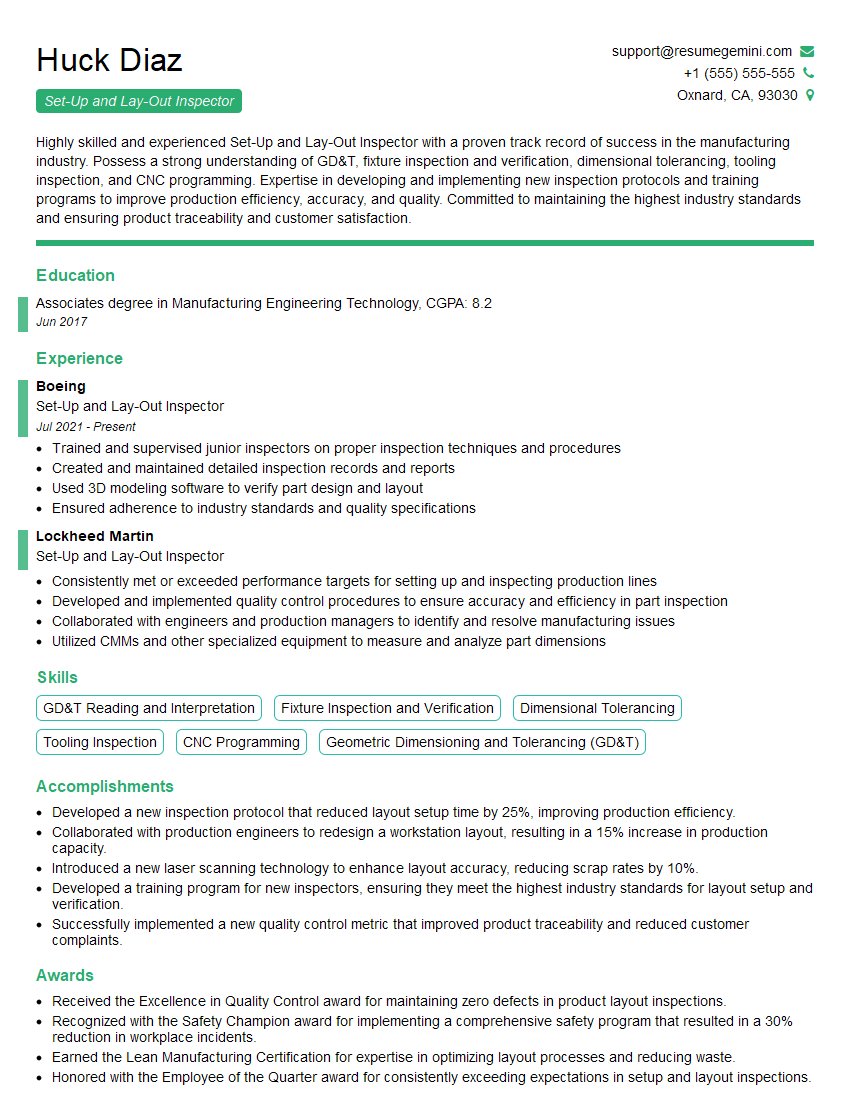

Huck Diaz

Set-Up and Lay-Out Inspector

Summary

Highly skilled and experienced Set-Up and Lay-Out Inspector with a proven track record of success in the manufacturing industry. Possess a strong understanding of GD&T, fixture inspection and verification, dimensional tolerancing, tooling inspection, and CNC programming. Expertise in developing and implementing new inspection protocols and training programs to improve production efficiency, accuracy, and quality. Committed to maintaining the highest industry standards and ensuring product traceability and customer satisfaction.

Education

Associates degree in Manufacturing Engineering Technology

June 2017

Skills

- GD&T Reading and Interpretation

- Fixture Inspection and Verification

- Dimensional Tolerancing

- Tooling Inspection

- CNC Programming

- Geometric Dimensioning and Tolerancing (GD&T)

Work Experience

Set-Up and Lay-Out Inspector

- Trained and supervised junior inspectors on proper inspection techniques and procedures

- Created and maintained detailed inspection records and reports

- Used 3D modeling software to verify part design and layout

- Ensured adherence to industry standards and quality specifications

Set-Up and Lay-Out Inspector

- Consistently met or exceeded performance targets for setting up and inspecting production lines

- Developed and implemented quality control procedures to ensure accuracy and efficiency in part inspection

- Collaborated with engineers and production managers to identify and resolve manufacturing issues

- Utilized CMMs and other specialized equipment to measure and analyze part dimensions

Accomplishments

- Developed a new inspection protocol that reduced layout setup time by 25%, improving production efficiency.

- Collaborated with production engineers to redesign a workstation layout, resulting in a 15% increase in production capacity.

- Introduced a new laser scanning technology to enhance layout accuracy, reducing scrap rates by 10%.

- Developed a training program for new inspectors, ensuring they meet the highest industry standards for layout setup and verification.

- Successfully implemented a new quality control metric that improved product traceability and reduced customer complaints.

Awards

- Received the Excellence in Quality Control award for maintaining zero defects in product layout inspections.

- Recognized with the Safety Champion award for implementing a comprehensive safety program that resulted in a 30% reduction in workplace incidents.

- Earned the Lean Manufacturing Certification for expertise in optimizing layout processes and reducing waste.

- Honored with the Employee of the Quarter award for consistently exceeding expectations in setup and layout inspections.

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Set-Up and Lay-Out Inspector

- Highlight your experience in developing and implementing new inspection protocols that have significantly improved production efficiency.

- Showcase your ability to collaborate with production engineers to optimize workstation layouts and increase production capacity.

- Emphasize your expertise in using advanced technologies, such as laser scanning, to enhance layout accuracy and reduce scrap rates.

- Demonstrate your commitment to training and developing new inspectors to maintain the highest industry standards.

Essential Experience Highlights for a Strong Set-Up and Lay-Out Inspector Resume

- Develop and implement new inspection protocols to streamline layout setup processes and reduce production time.

- Collaborate with production engineers to redesign workstation layouts for increased production capacity.

- Introduce advanced technologies, such as laser scanning, to enhance layout accuracy and minimize scrap rates.

- Create and deliver training programs for new inspectors to ensure they meet industry standards for layout setup and verification.

- Establish quality control metrics to improve product traceability, reduce customer complaints, and maintain product quality.

- Inspect and verify fixtures, tooling, and CNC programs to ensure they meet design specifications and dimensional tolerances.

- Analyze GD&T drawings and ensure that products conform to the specified geometric dimensions and tolerances.

Frequently Asked Questions (FAQ’s) For Set-Up and Lay-Out Inspector

What are the key skills and qualifications required for a Set-Up and Lay-Out Inspector?

Key skills include GD&T reading and interpretation, fixture inspection and verification, dimensional tolerancing, tooling inspection, CNC programming, and geometric dimensioning and tolerancing (GD&T). A strong understanding of manufacturing processes, quality control principles, and industry standards is also essential.

What are the primary responsibilities of a Set-Up and Lay-Out Inspector?

Primary responsibilities include developing and implementing inspection protocols, collaborating with production engineers to optimize layouts, introducing advanced technologies to enhance accuracy, training new inspectors, and establishing quality control metrics to ensure product traceability and customer satisfaction.

What are the career advancement opportunities for a Set-Up and Lay-Out Inspector?

With experience and additional training, Set-Up and Lay-Out Inspectors can advance to roles such as Quality Inspector, Manufacturing Engineer, or Production Supervisor.

What is the job outlook for Set-Up and Lay-Out Inspectors?

The job outlook for Set-Up and Lay-Out Inspectors is expected to grow faster than average in the coming years due to increasing demand for quality control and manufacturing efficiency.

What are the typical work environments for Set-Up and Lay-Out Inspectors?

Set-Up and Lay-Out Inspectors typically work in manufacturing facilities, production plants, or quality control laboratories. They may work in a variety of settings, including clean rooms, workshops, or assembly lines.

What certifications or training programs are beneficial for Set-Up and Lay-Out Inspectors?

Certifications such as Certified Quality Inspector (CQI) or Certified Manufacturing Engineer (CMfgE) can enhance your credibility and demonstrate your commitment to the profession. Training programs in GD&T, CNC programming, and other relevant topics can also be beneficial.

What are the key challenges faced by Set-Up and Lay-Out Inspectors?

Key challenges include keeping up with advances in manufacturing technology, ensuring compliance with industry standards and regulations, and maintaining high levels of accuracy and precision in their work.