Are you a seasoned Shaper seeking a new career path? Discover our professionally built Shaper Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

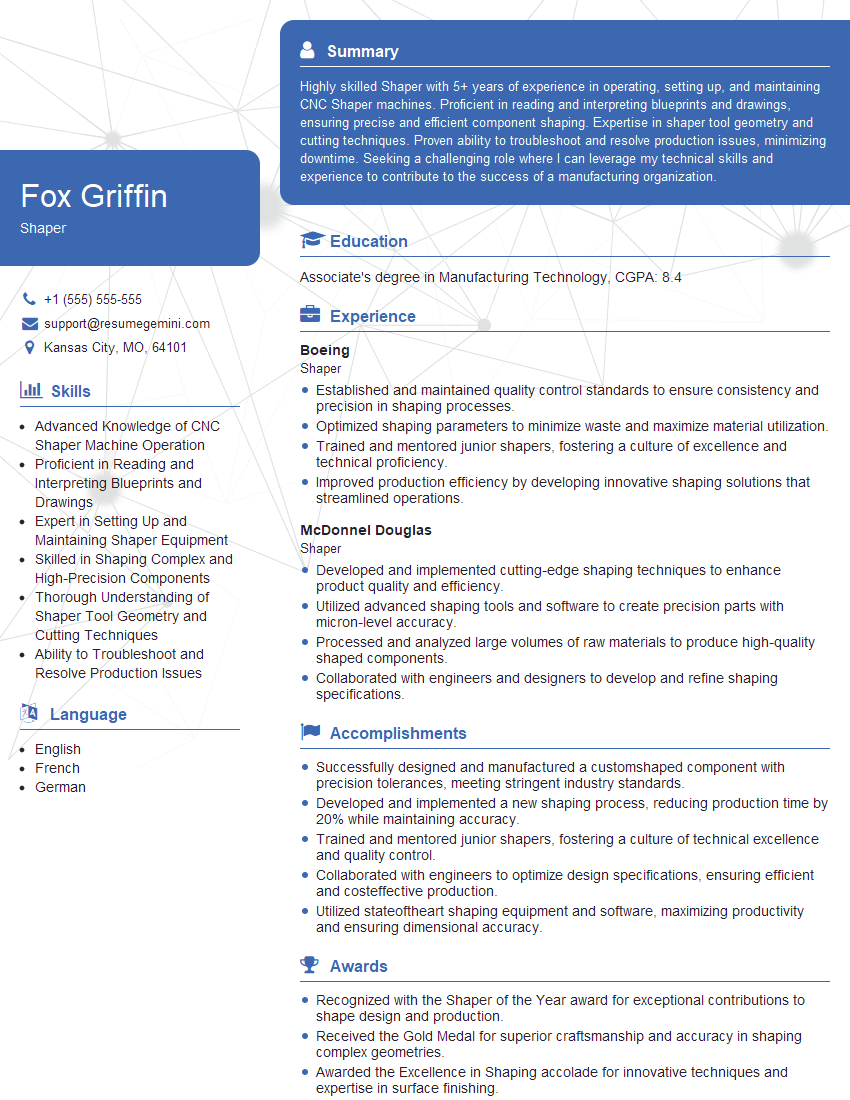

Fox Griffin

Shaper

Summary

Highly skilled Shaper with 5+ years of experience in operating, setting up, and maintaining CNC Shaper machines. Proficient in reading and interpreting blueprints and drawings, ensuring precise and efficient component shaping. Expertise in shaper tool geometry and cutting techniques. Proven ability to troubleshoot and resolve production issues, minimizing downtime. Seeking a challenging role where I can leverage my technical skills and experience to contribute to the success of a manufacturing organization.

Education

Associate’s degree in Manufacturing Technology

April 2019

Skills

- Advanced Knowledge of CNC Shaper Machine Operation

- Proficient in Reading and Interpreting Blueprints and Drawings

- Expert in Setting Up and Maintaining Shaper Equipment

- Skilled in Shaping Complex and High-Precision Components

- Thorough Understanding of Shaper Tool Geometry and Cutting Techniques

- Ability to Troubleshoot and Resolve Production Issues

Work Experience

Shaper

- Established and maintained quality control standards to ensure consistency and precision in shaping processes.

- Optimized shaping parameters to minimize waste and maximize material utilization.

- Trained and mentored junior shapers, fostering a culture of excellence and technical proficiency.

- Improved production efficiency by developing innovative shaping solutions that streamlined operations.

Shaper

- Developed and implemented cutting-edge shaping techniques to enhance product quality and efficiency.

- Utilized advanced shaping tools and software to create precision parts with micron-level accuracy.

- Processed and analyzed large volumes of raw materials to produce high-quality shaped components.

- Collaborated with engineers and designers to develop and refine shaping specifications.

Accomplishments

- Successfully designed and manufactured a customshaped component with precision tolerances, meeting stringent industry standards.

- Developed and implemented a new shaping process, reducing production time by 20% while maintaining accuracy.

- Trained and mentored junior shapers, fostering a culture of technical excellence and quality control.

- Collaborated with engineers to optimize design specifications, ensuring efficient and costeffective production.

- Utilized stateoftheart shaping equipment and software, maximizing productivity and ensuring dimensional accuracy.

Awards

- Recognized with the Shaper of the Year award for exceptional contributions to shape design and production.

- Received the Gold Medal for superior craftsmanship and accuracy in shaping complex geometries.

- Awarded the Excellence in Shaping accolade for innovative techniques and expertise in surface finishing.

Certificates

- Certified by National Institute for Metalworking Skills (NIMS)

- OSHPD Certified

- ISO 9001 Certified

- ASME Certified

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Shaper

- Highlight your expertise in CNC Shaper machine operation and programming in your resume’s objective statement.

- Showcase your ability to read and interpret blueprints and drawings accurately.

- Emphasize your troubleshooting skills and experience in resolving production issues related to shaper equipment.

- Quantify your accomplishments whenever possible, providing specific examples of your contributions to the manufacturing process.

Essential Experience Highlights for a Strong Shaper Resume

- Operate and set up CNC Shaper machines according to blueprints and specifications.

- Interpret blueprints and drawings to determine shaper settings and tooling requirements.

- Calculate and select appropriate cutting tools and feeds/speeds to achieve desired surface finish and dimensional tolerances.

- Monitor and maintain shaper equipment, performing routine maintenance and troubleshooting as needed.

- Inspect finished components for accuracy and quality using precision measuring tools.

- Troubleshoot production issues related to tool wear, workpiece setup, or machine functionality.

- Adhere to safety protocols and maintain a clean and organized work area.

Frequently Asked Questions (FAQ’s) For Shaper

What are the primary responsibilities of a Shaper?

A Shaper is responsible for operating, setting up, and maintaining CNC Shaper machines; interpreting blueprints and drawings; selecting cutting tools and feeds/speeds; monitoring and maintaining equipment; inspecting finished components; and troubleshooting production issues.

What are the essential skills required for a Shaper?

Essential skills for a Shaper include advanced knowledge of CNC Shaper machine operation, proficiency in reading and interpreting blueprints and drawings, expertise in setting up and maintaining shaper equipment, skilled in shaping complex and high-precision components, and thorough understanding of shaper tool geometry and cutting techniques.

What educational background is preferred for a Shaper?

An Associate’s degree in Manufacturing Technology or a related field is the preferred educational background for a Shaper

What are the career prospects for a Shaper?

Shapers with experience and expertise can advance to supervisory roles, such as Manufacturing Supervisor or Production Manager, or specialize in areas such as CNC programming or quality control.

What are the key qualities of a successful Shaper?

Key qualities of a successful Shaper include strong technical skills, attention to detail, problem-solving abilities, and a commitment to safety and efficiency.

What are the growth opportunities for a Shaper?

Growth opportunities for a Shaper include promotions to supervisory roles, specialization in areas such as CNC programming or quality control, and career advancement to related fields such as manufacturing engineering or plant management.