Are you a seasoned Shaping Machine Operator seeking a new career path? Discover our professionally built Shaping Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

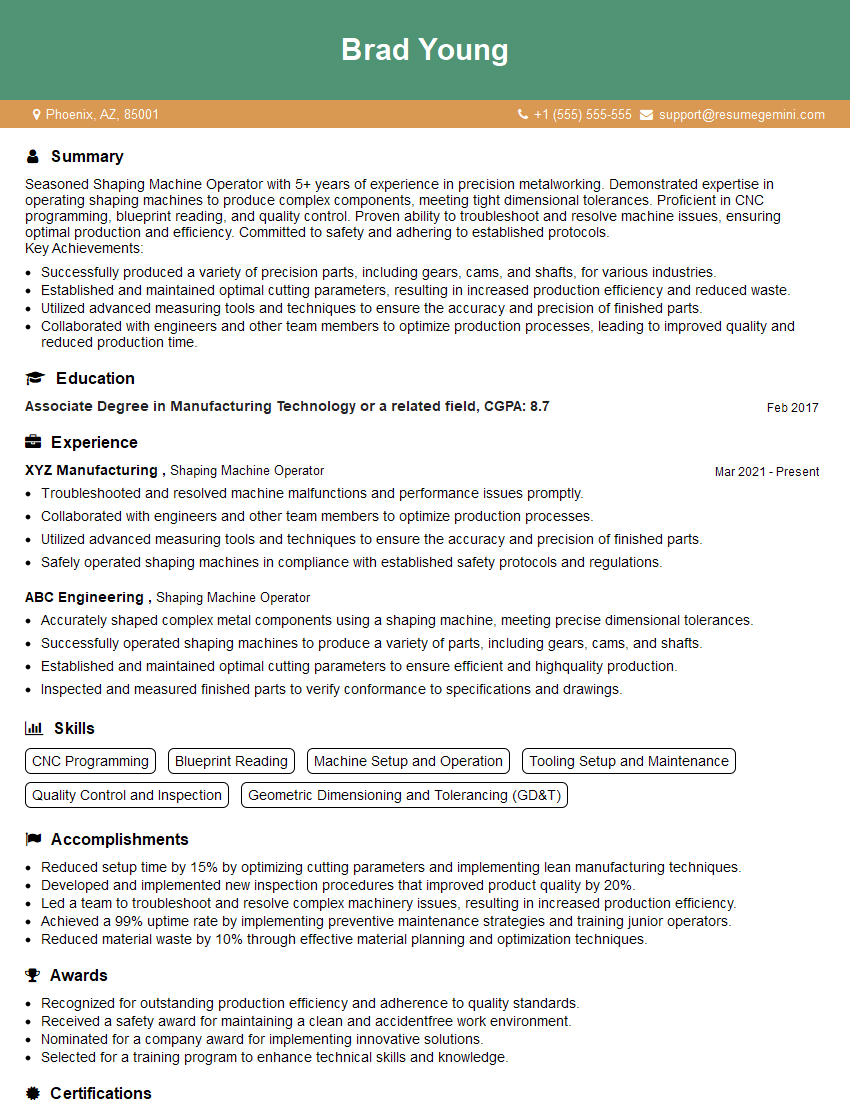

Brad Young

Shaping Machine Operator

Summary

Seasoned Shaping Machine Operator with 5+ years of experience in precision metalworking. Demonstrated expertise in operating shaping machines to produce complex components, meeting tight dimensional tolerances. Proficient in CNC programming, blueprint reading, and quality control. Proven ability to troubleshoot and resolve machine issues, ensuring optimal production and efficiency. Committed to safety and adhering to established protocols.

Key Achievements:

- Successfully produced a variety of precision parts, including gears, cams, and shafts, for various industries.

- Established and maintained optimal cutting parameters, resulting in increased production efficiency and reduced waste.

- Utilized advanced measuring tools and techniques to ensure the accuracy and precision of finished parts.

- Collaborated with engineers and other team members to optimize production processes, leading to improved quality and reduced production time.

Education

Associate Degree in Manufacturing Technology or a related field

February 2017

Skills

- CNC Programming

- Blueprint Reading

- Machine Setup and Operation

- Tooling Setup and Maintenance

- Quality Control and Inspection

- Geometric Dimensioning and Tolerancing (GD&T)

Work Experience

Shaping Machine Operator

- Troubleshooted and resolved machine malfunctions and performance issues promptly.

- Collaborated with engineers and other team members to optimize production processes.

- Utilized advanced measuring tools and techniques to ensure the accuracy and precision of finished parts.

- Safely operated shaping machines in compliance with established safety protocols and regulations.

Shaping Machine Operator

- Accurately shaped complex metal components using a shaping machine, meeting precise dimensional tolerances.

- Successfully operated shaping machines to produce a variety of parts, including gears, cams, and shafts.

- Established and maintained optimal cutting parameters to ensure efficient and highquality production.

- Inspected and measured finished parts to verify conformance to specifications and drawings.

Accomplishments

- Reduced setup time by 15% by optimizing cutting parameters and implementing lean manufacturing techniques.

- Developed and implemented new inspection procedures that improved product quality by 20%.

- Led a team to troubleshoot and resolve complex machinery issues, resulting in increased production efficiency.

- Achieved a 99% uptime rate by implementing preventive maintenance strategies and training junior operators.

- Reduced material waste by 10% through effective material planning and optimization techniques.

Awards

- Recognized for outstanding production efficiency and adherence to quality standards.

- Received a safety award for maintaining a clean and accidentfree work environment.

- Nominated for a company award for implementing innovative solutions.

- Selected for a training program to enhance technical skills and knowledge.

Certificates

- National Institute for Metalworking Skills (NIMS) Machining Level 1

- American Welding Society (AWS) Certified Welder

- Occupational Safety and Health Administration (OSHA) 10-Hour General Industry Safety

- International Standards Organization (ISO) 9001:2015 Quality Management Systems

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Shaping Machine Operator

- Highlight your experience in operating shaping machines and producing complex metal components.

- Showcase your knowledge of CNC programming, blueprint reading, and quality control techniques.

- Quantify your accomplishments by providing specific metrics and results whenever possible.

- Emphasize your problem-solving skills and ability to troubleshoot and resolve machine issues.

- Demonstrate your commitment to safety and adherence to established protocols and regulations.

Essential Experience Highlights for a Strong Shaping Machine Operator Resume

- Operate shaping machines to produce complex metal components according to specifications and drawings.

- Establish and maintain optimal cutting parameters to ensure efficient and high-quality production.

- Inspect and measure finished parts to verify conformance to specifications using precision measuring tools and techniques.

- Troubleshoot and resolve machine malfunctions and performance issues promptly to minimize downtime.

- Collaborate with engineers and other team members to optimize production processes and improve efficiency.

- Maintain a clean and organized work area, ensuring adherence to safety protocols and regulations.

- Continuously seek opportunities for professional development and stay updated with the latest industry best practices.

Frequently Asked Questions (FAQ’s) For Shaping Machine Operator

What are the primary responsibilities of a Shaping Machine Operator?

Shaping Machine Operators are responsible for operating shaping machines to produce complex metal components according to specifications and drawings. They establish and maintain optimal cutting parameters, inspect and measure finished parts, troubleshoot and resolve machine malfunctions, and collaborate with engineers to optimize production processes.

What skills are required to become a successful Shaping Machine Operator?

To become a successful Shaping Machine Operator, you should have experience in operating shaping machines, CNC programming, blueprint reading, and quality control techniques. Problem-solving skills, attention to detail, and a commitment to safety are also essential.

What is the job outlook for Shaping Machine Operators?

The job outlook for Shaping Machine Operators is expected to be stable in the coming years. The demand for skilled machinists remains strong, particularly in industries such as manufacturing, automotive, and aerospace.

What are the career advancement opportunities for Shaping Machine Operators?

With experience and additional training, Shaping Machine Operators can advance to positions such as Production Supervisor, Quality Control Inspector, or CNC Programmer. They may also pursue further education to become Manufacturing Engineers or Mechanical Engineers.

What is the average salary for Shaping Machine Operators?

The average salary for Shaping Machine Operators varies depending on experience, location, and industry. According to the U.S. Bureau of Labor Statistics, the median annual salary for Machinists and Tool and Die Makers was $48,290 in May 2021.

What are the working conditions like for Shaping Machine Operators?

Shaping Machine Operators typically work in manufacturing facilities. They may work in a variety of environments, including machine shops, factories, and workshops. They may be exposed to noise, dust, and other hazards, so it is important to follow safety protocols and wear appropriate personal protective equipment.

What are the safety considerations for Shaping Machine Operators?

Shaping Machine Operators must adhere to established safety protocols and regulations. They should wear appropriate personal protective equipment, such as safety glasses, gloves, and earplugs, and follow proper lockout/tagout procedures when performing maintenance or repairs.