Are you a seasoned Sheet Metal Computer Numerically Controlled (CNC) Programmer seeking a new career path? Discover our professionally built Sheet Metal Computer Numerically Controlled (CNC) Programmer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

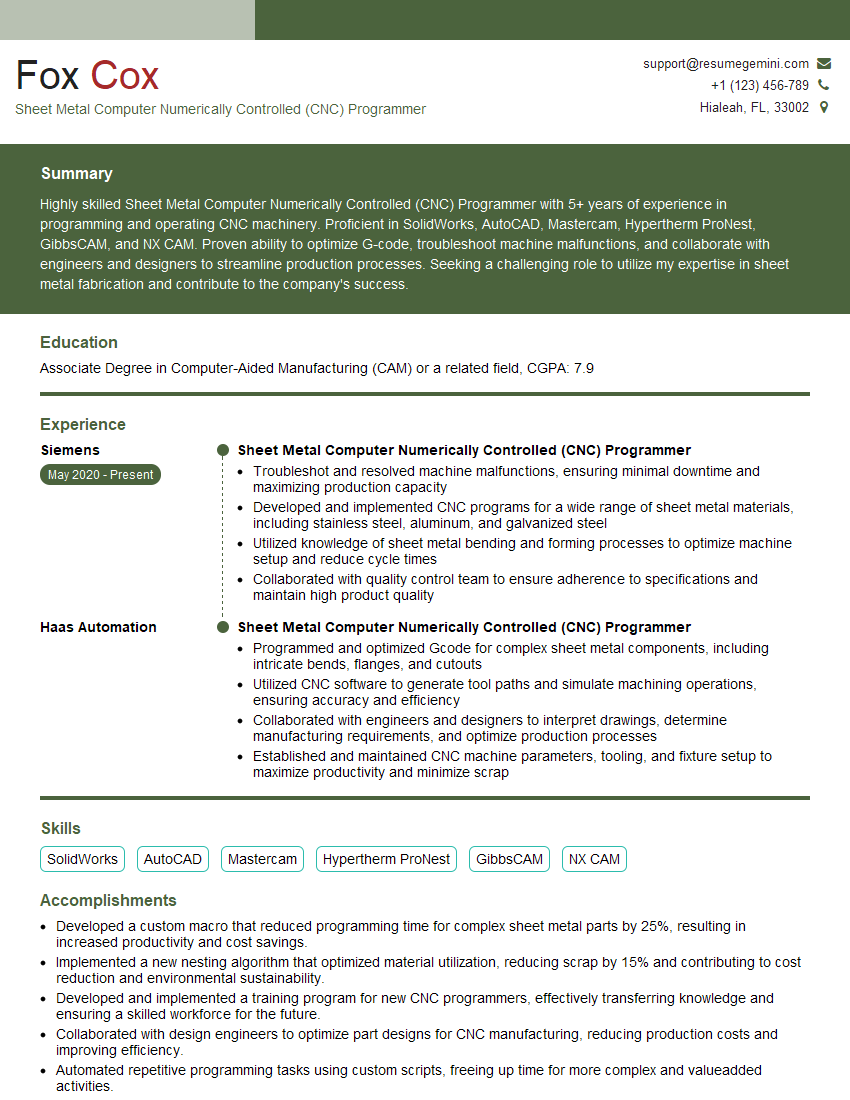

Fox Cox

Sheet Metal Computer Numerically Controlled (CNC) Programmer

Summary

Highly skilled Sheet Metal Computer Numerically Controlled (CNC) Programmer with 5+ years of experience in programming and operating CNC machinery. Proficient in SolidWorks, AutoCAD, Mastercam, Hypertherm ProNest, GibbsCAM, and NX CAM. Proven ability to optimize G-code, troubleshoot machine malfunctions, and collaborate with engineers and designers to streamline production processes. Seeking a challenging role to utilize my expertise in sheet metal fabrication and contribute to the company’s success.

Education

Associate Degree in Computer-Aided Manufacturing (CAM) or a related field

April 2016

Skills

- SolidWorks

- AutoCAD

- Mastercam

- Hypertherm ProNest

- GibbsCAM

- NX CAM

Work Experience

Sheet Metal Computer Numerically Controlled (CNC) Programmer

- Troubleshot and resolved machine malfunctions, ensuring minimal downtime and maximizing production capacity

- Developed and implemented CNC programs for a wide range of sheet metal materials, including stainless steel, aluminum, and galvanized steel

- Utilized knowledge of sheet metal bending and forming processes to optimize machine setup and reduce cycle times

- Collaborated with quality control team to ensure adherence to specifications and maintain high product quality

Sheet Metal Computer Numerically Controlled (CNC) Programmer

- Programmed and optimized Gcode for complex sheet metal components, including intricate bends, flanges, and cutouts

- Utilized CNC software to generate tool paths and simulate machining operations, ensuring accuracy and efficiency

- Collaborated with engineers and designers to interpret drawings, determine manufacturing requirements, and optimize production processes

- Established and maintained CNC machine parameters, tooling, and fixture setup to maximize productivity and minimize scrap

Accomplishments

- Developed a custom macro that reduced programming time for complex sheet metal parts by 25%, resulting in increased productivity and cost savings.

- Implemented a new nesting algorithm that optimized material utilization, reducing scrap by 15% and contributing to cost reduction and environmental sustainability.

- Developed and implemented a training program for new CNC programmers, effectively transferring knowledge and ensuring a skilled workforce for the future.

- Collaborated with design engineers to optimize part designs for CNC manufacturing, reducing production costs and improving efficiency.

- Automated repetitive programming tasks using custom scripts, freeing up time for more complex and valueadded activities.

Awards

- Received the CNC Programmer of the Year award at the annual industry conference, recognizing exceptional skills in Sheet Metal CNC programming.

- Honored with the Excellence in CNC Programming award from the company for consistently delivering highquality programs that met or exceeded customer specifications.

- Received recognition for Outstanding Contribution to CNC Programming from industry peers for sharing innovative techniques and best practices at industry workshops.

- Honored with the Technical Excellence award by the company for exceptional performance in troubleshooting complex CNC programming challenges.

Certificates

- Certified SolidWorks Professional (CSWP)

- Certified AutoCAD Professional (CAP)

- Mastercam Certified Professional (MCP)

- Hypertherm ProNest Certified Operator (HPCO)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Sheet Metal Computer Numerically Controlled (CNC) Programmer

- Highlight your proficiency in relevant software, such as SolidWorks, AutoCAD, and Mastercam.

- Quantify your accomplishments whenever possible, such as reducing cycle times or increasing production efficiency.

- Showcase your ability to work independently and as part of a team.

- Obtain industry certifications, such as the Certified Manufacturing Technologist (CMfgT) or the Certified CNC Programmer (CCNP).

- Network with professionals in the field and attend industry events to stay updated on the latest technologies.

Essential Experience Highlights for a Strong Sheet Metal Computer Numerically Controlled (CNC) Programmer Resume

- Programmed and optimized G-code for complex sheet metal components, ensuring accuracy and efficiency.

- Utilized CNC software to generate tool paths and simulate machining operations, maximizing productivity and minimizing scrap.

- Collaborated with engineers and designers to interpret drawings, determine manufacturing requirements, and optimize production processes.

- Established and maintained CNC machine parameters, tooling, and fixture setup to enhance productivity and minimize downtime.

- Troubleshot and resolved machine malfunctions, ensuring minimal downtime and maximizing production capacity.

- Developed and implemented CNC programs for a wide range of sheet metal materials, including stainless steel, aluminum, and galvanized steel.

- Collaborated with quality control team to ensure adherence to specifications and maintain high product quality.

Frequently Asked Questions (FAQ’s) For Sheet Metal Computer Numerically Controlled (CNC) Programmer

What is the role of a Sheet Metal CNC Programmer?

A Sheet Metal CNC Programmer is responsible for creating and optimizing G-code programs for CNC machines used in sheet metal fabrication. They collaborate with engineers and designers to determine manufacturing requirements, select appropriate tooling, and ensure that parts are produced according to specifications.

What skills are required to be a successful Sheet Metal CNC Programmer?

Successful Sheet Metal CNC Programmers typically have a strong understanding of CNC programming, sheet metal fabrication processes, and relevant software applications. They are also proficient in troubleshooting and problem-solving, and possess excellent communication and teamwork skills.

What are the career prospects for Sheet Metal CNC Programmers?

Sheet Metal CNC Programmers are in high demand in various industries, including manufacturing, automotive, aerospace, and construction. With experience and specialized skills, they can advance to roles such as CNC Machinist, Manufacturing Engineer, or Production Supervisor.

How can I improve my skills as a Sheet Metal CNC Programmer?

To enhance your skills as a Sheet Metal CNC Programmer, consider obtaining industry certifications, attending training programs, and staying updated on the latest software and technologies. Additionally, seeking out opportunities to work on complex projects and collaborating with experienced professionals can contribute to your professional growth.

What is the job outlook for Sheet Metal CNC Programmers?

The job outlook for Sheet Metal CNC Programmers is expected to be positive in the coming years. The increasing use of CNC technology in manufacturing and the growing demand for skilled CNC programmers are expected to drive employment opportunities.

What is the average salary for Sheet Metal CNC Programmers?

The average salary for Sheet Metal CNC Programmers varies depending on experience, location, and industry. According to Indeed, the average salary for Sheet Metal CNC Programmers in the United States is around $60,000 per year.

What are the benefits of working as a Sheet Metal CNC Programmer?

Benefits of working as a Sheet Metal CNC Programmer include competitive salaries, opportunities for career advancement, job security due to the high demand for skilled CNC programmers, and the satisfaction of working with cutting-edge technology.