Are you a seasoned Sheet Metal Fabricator seeking a new career path? Discover our professionally built Sheet Metal Fabricator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

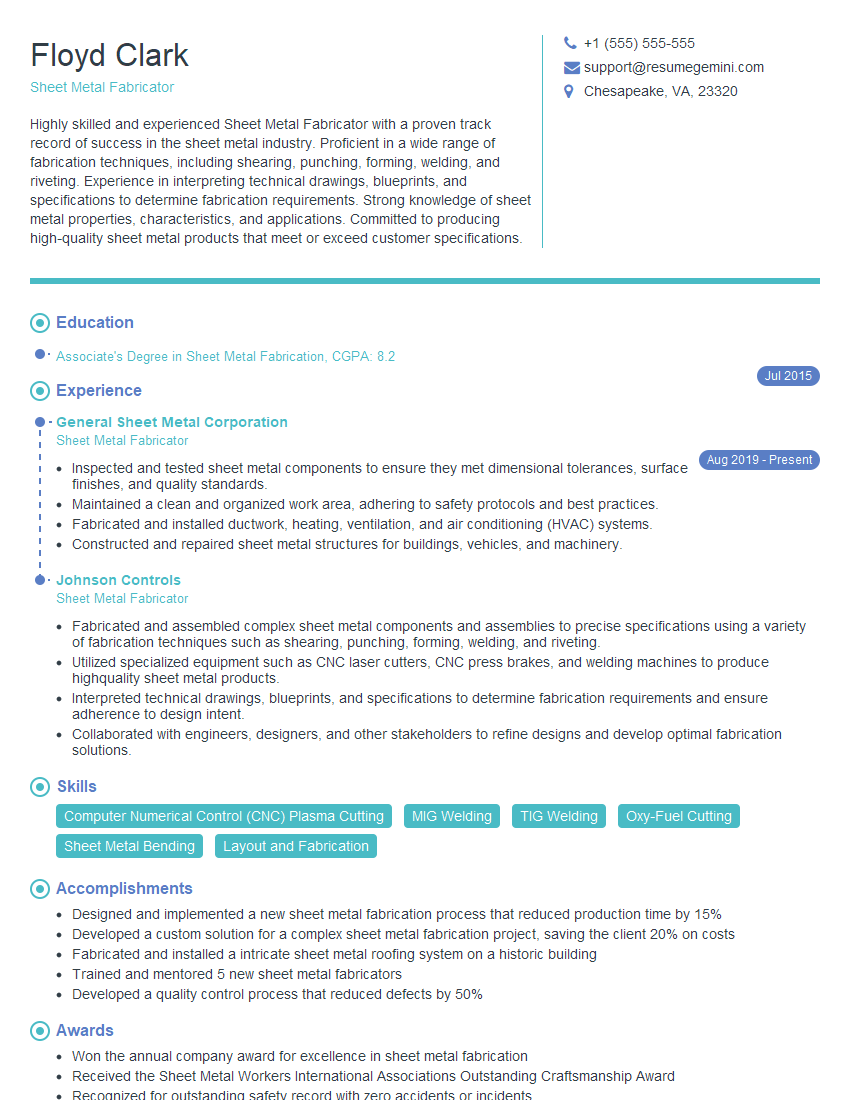

Floyd Clark

Sheet Metal Fabricator

Summary

Highly skilled and experienced Sheet Metal Fabricator with a proven track record of success in the sheet metal industry. Proficient in a wide range of fabrication techniques, including shearing, punching, forming, welding, and riveting. Experience in interpreting technical drawings, blueprints, and specifications to determine fabrication requirements. Strong knowledge of sheet metal properties, characteristics, and applications. Committed to producing high-quality sheet metal products that meet or exceed customer specifications.

Education

Associate’s Degree in Sheet Metal Fabrication

July 2015

Skills

- Computer Numerical Control (CNC) Plasma Cutting

- MIG Welding

- TIG Welding

- Oxy-Fuel Cutting

- Sheet Metal Bending

- Layout and Fabrication

Work Experience

Sheet Metal Fabricator

- Inspected and tested sheet metal components to ensure they met dimensional tolerances, surface finishes, and quality standards.

- Maintained a clean and organized work area, adhering to safety protocols and best practices.

- Fabricated and installed ductwork, heating, ventilation, and air conditioning (HVAC) systems.

- Constructed and repaired sheet metal structures for buildings, vehicles, and machinery.

Sheet Metal Fabricator

- Fabricated and assembled complex sheet metal components and assemblies to precise specifications using a variety of fabrication techniques such as shearing, punching, forming, welding, and riveting.

- Utilized specialized equipment such as CNC laser cutters, CNC press brakes, and welding machines to produce highquality sheet metal products.

- Interpreted technical drawings, blueprints, and specifications to determine fabrication requirements and ensure adherence to design intent.

- Collaborated with engineers, designers, and other stakeholders to refine designs and develop optimal fabrication solutions.

Accomplishments

- Designed and implemented a new sheet metal fabrication process that reduced production time by 15%

- Developed a custom solution for a complex sheet metal fabrication project, saving the client 20% on costs

- Fabricated and installed a intricate sheet metal roofing system on a historic building

- Trained and mentored 5 new sheet metal fabricators

- Developed a quality control process that reduced defects by 50%

Awards

- Won the annual company award for excellence in sheet metal fabrication

- Received the Sheet Metal Workers International Associations Outstanding Craftsmanship Award

- Recognized for outstanding safety record with zero accidents or incidents

- Received the American Society of Heating, Refrigerating, and AirConditioning Engineers (ASHRAE) Excellence in Sheet Metal Fabrication Award

Certificates

- Certified Welding Inspector (CWI)

- National Institute for Metalworking Skills (NIMS) Certification

- American Welding Society (AWS) Certification

- Occupational Safety and Health Administration (OSHA) Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Sheet Metal Fabricator

- Highlight your experience and skills in sheet metal fabrication, including specific techniques and equipment.

- Showcase your ability to read and interpret technical drawings and blueprints.

- Emphasize your experience in collaborating with engineers and designers.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Proofread your resume carefully for any errors or inconsistencies.

Essential Experience Highlights for a Strong Sheet Metal Fabricator Resume

- Fabricated and assembled complex sheet metal components and assemblies to precise specifications using a variety of fabrication techniques.

- Utilized specialized equipment such as CNC laser cutters, CNC press brakes, and welding machines to produce high-quality sheet metal products.

- Interpreted technical drawings, blueprints, and specifications to determine fabrication requirements and ensure adherence to design intent.

- Collaborated with engineers, designers, and other stakeholders to refine designs and develop optimal fabrication solutions.

- Inspected and tested sheet metal components to ensure they met dimensional tolerances, surface finishes, and quality standards.

- Maintained a clean and organized work area, adhering to safety protocols and best practices.

Frequently Asked Questions (FAQ’s) For Sheet Metal Fabricator

What is the job outlook for sheet metal fabricators?

The job outlook for sheet metal fabricators is expected to be good over the next few years. The demand for sheet metal products is expected to increase as construction and manufacturing continue to grow.

What are the educational requirements for becoming a sheet metal fabricator?

Most sheet metal fabricators have a high school diploma or equivalent. Some employers may prefer candidates with an associate’s degree in sheet metal fabrication or a related field.

What are the skills needed to be a successful sheet metal fabricator?

Successful sheet metal fabricators have strong math and spatial reasoning skills. They are also able to read and interpret technical drawings and blueprints. Additionally, they must be able to operate a variety of sheet metal fabrication equipment.

What are the different types of sheet metal fabrication techniques?

There are a variety of sheet metal fabrication techniques, including shearing, punching, forming, welding, and riveting. Each technique has its own advantages and disadvantages, and the best technique for a particular job will depend on the materials being used and the desired results.

What are the safety precautions that should be taken when working with sheet metal?

When working with sheet metal, it is important to take precautions to avoid injury. These precautions include wearing proper safety gear, such as gloves, eye protection, and a dust mask. It is also important to be aware of the potential hazards of sheet metal, such as sharp edges and hot surfaces.

What is the difference between a sheet metal fabricator and a welder?

A sheet metal fabricator is responsible for cutting, forming, and assembling sheet metal into a variety of products. A welder, on the other hand, is responsible for joining metal pieces together using a welding torch.